Radiant heater for heating the building material in a laser sintering device

A radiation heater, laser sintering technology, applied in the field of radiation heaters, can solve the problem of no rapid temperature control or adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

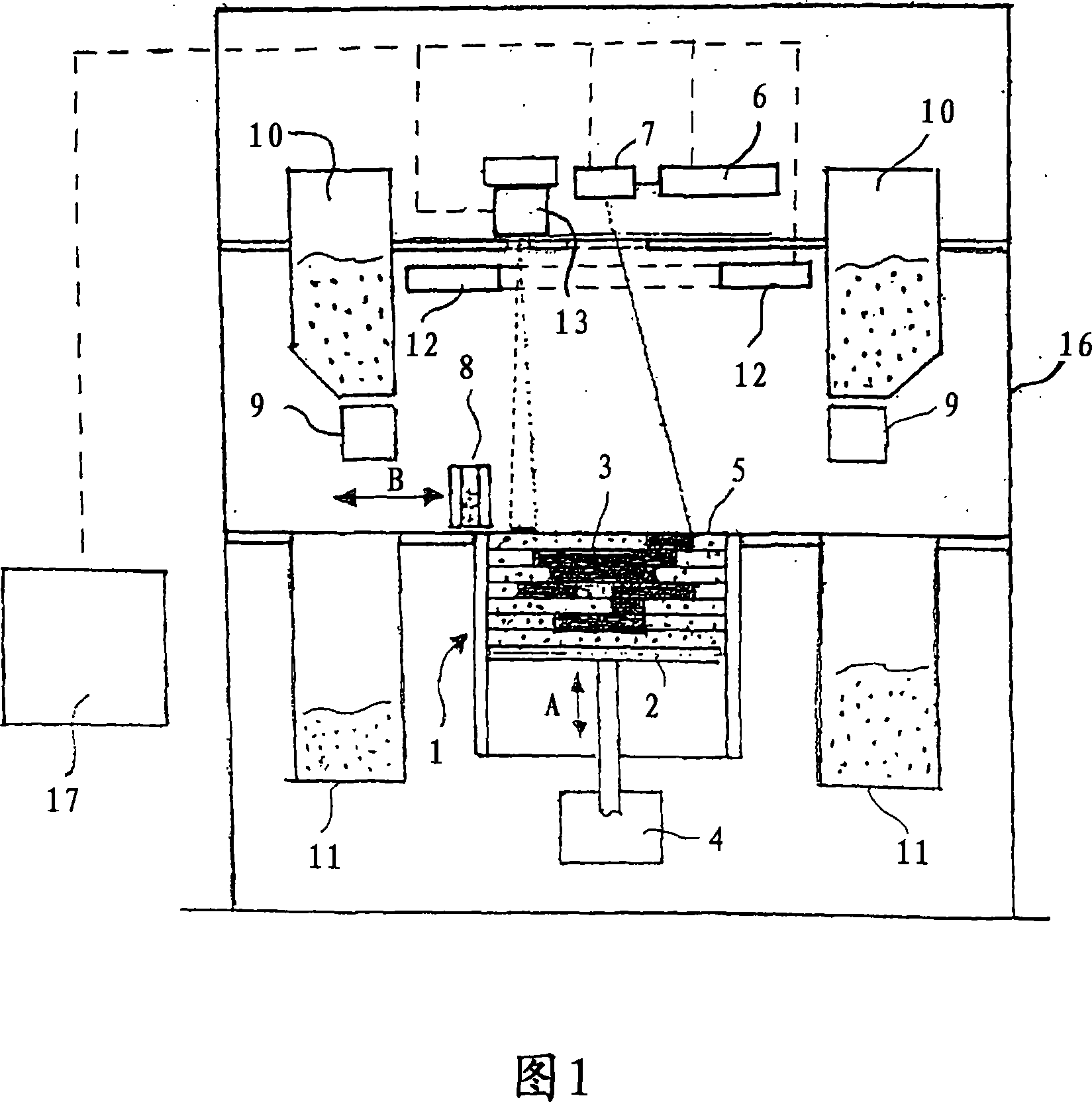

[0019] FIG. 1 shows a laser sintering device with radiation heating according to the invention. The laser sintering device includes a container 1 that is open upwards. Arranged in the container 1 is a support 2 for supporting an object 3 to be formed. The support 2 can be moved up and down in the vertical direction A in the container 1 by means of a drive device 4 . The upper edge of the container 1 defines a working surface 5 . An irradiation device 6 in the form of a laser is located above the working surface 5 and emits a directed laser beam which is deflected onto the working surface 5 by means of a deflection device 7 . Furthermore, an application device 8 is provided for applying a layer of powder material to be cured onto the surface of the support 2 or a layer that is finally cured. The coating device can be moved back and forth on the working surface 5 by a drive device, which is schematically indicated by arrow B. The coating device 8 is fed by two powder storage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com