New type sensor for measuring temperature of bearing

A technology for temperature measurement sensors and bearings, applied in the fields of instrumentation and temperature measurement sensors, can solve the problems of lead breakage, connecting pipe bending, squeezing or breaking of rigid connecting pipes, etc., so as to prevent squashing or breaking and increase guiding performance , the effect of reducing the heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

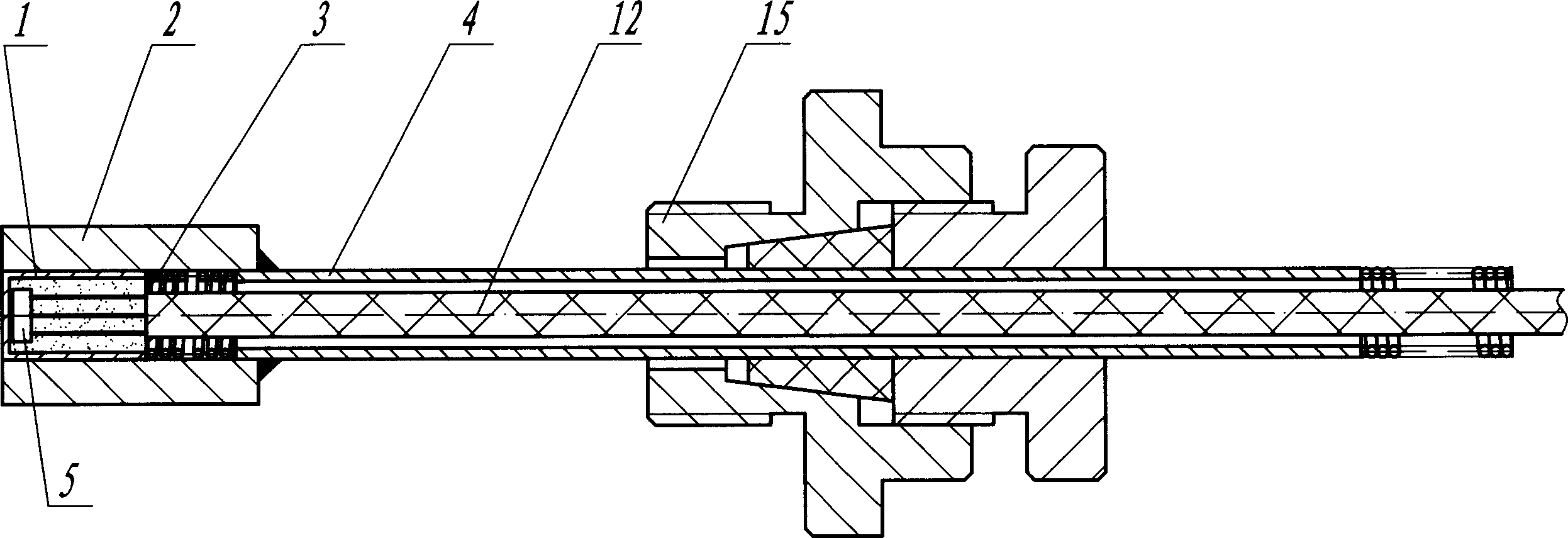

[0014] figure 1 It is the basic structure of the current bearing temperature sensor. The outer surface of the short temperature sensing head (1) is in full contact with the surface of the inner hole of the short guide sleeve (2), and the end face of the short guide sleeve (2) is in full contact with the end face of the bearing. The temperature measuring sensor has high thermal inertia and poor sensitivity; the lead wire ( 12) The bonding area between the original adhesive (3) and the short temperature sensing head (1) is small, and it is easy to fall off or break during use, installation and transportation; the rigid connecting pipe (4) is often squeezed flat during bending or break off, causing the lead wire (12) to crack or break.

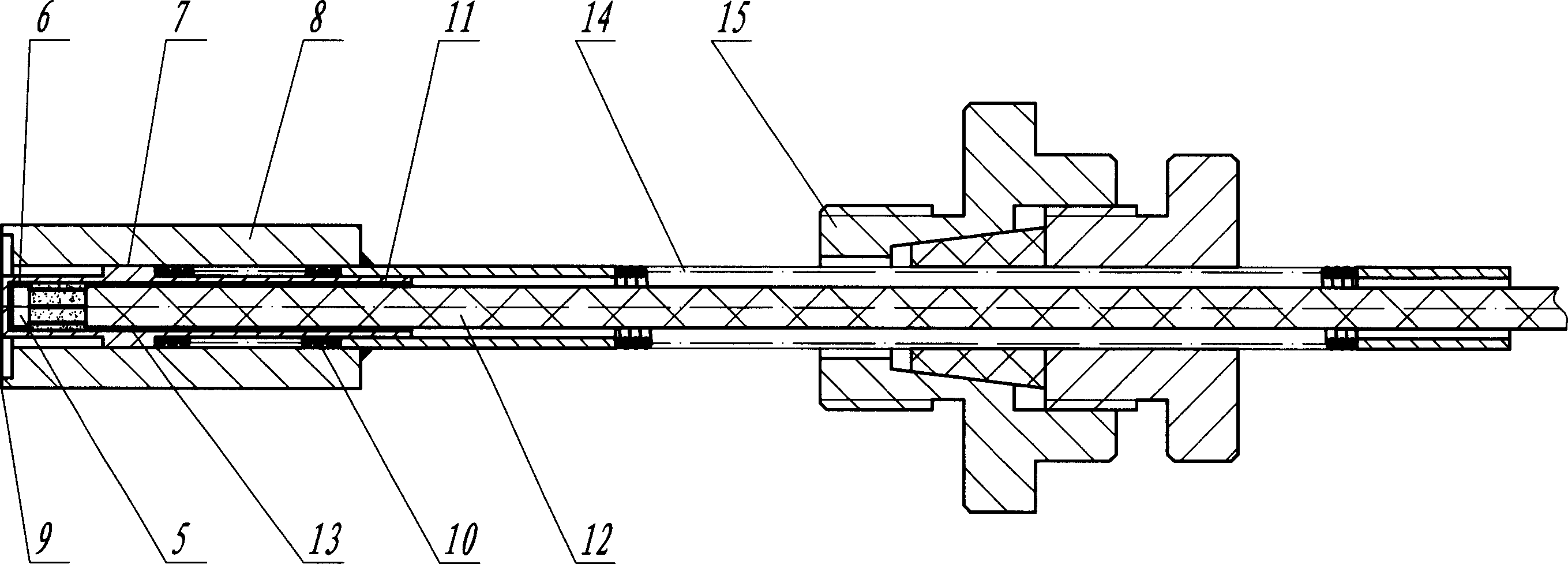

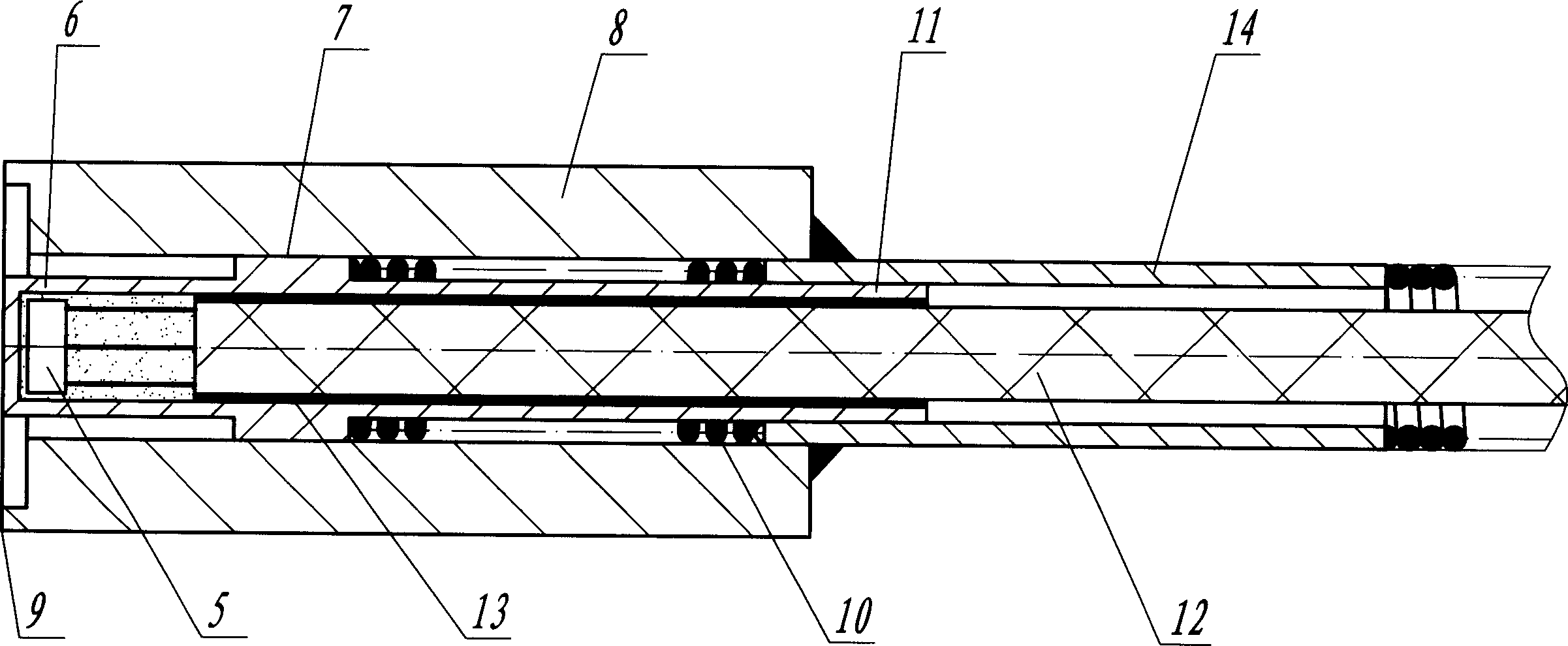

[0015] figure 2 It is the basic structure of a new bearing temperature sensor. The new-type bearing temperature mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com