Fire-retardant low concentration gas burner

A low-concentration gas and burner technology, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of atmospheric environmental pollution and high probability of tempering, and achieve reduced NOx emissions, fast cooling speed, and heat inert little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

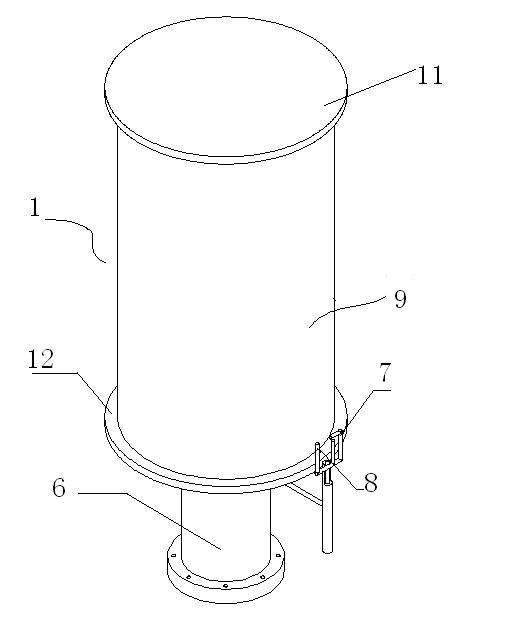

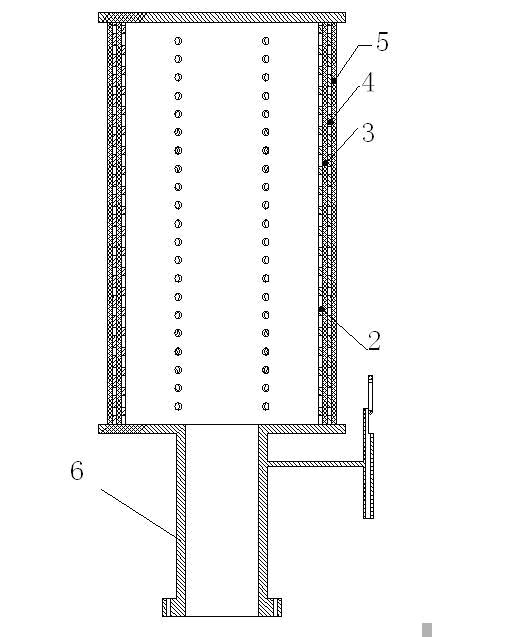

[0031] As shown in the figure, the flame-retardant low-concentration gas burner of the present invention includes a combustion cylinder 1, which includes a cylinder body 9 with a multi-layer structure and an upper end that is respectively arranged on the cylinder body and the lower end surface and is closely connected with the cylinder body. The cover 11, the lower end cover 12, and the cylinder body 9 are the support layer 2, the fire resistance layer 3, the diverter plate layer 4 and the combustion layer 5 in sequence from the inside to the outside. In this embodiment, the upper end cover 11 adopts a single-layer structure made of high temperature resistant metal material.

[0032] Wherein, the support layer 2 can adopt a fence-like structure made of a high-temperature-resistant metal material, and its function is to support the metal fibers of the fire-resistant layer. In this embodiment, the support layer is made of a fence-like structure made of a high-temperature-resistan...

Embodiment 2

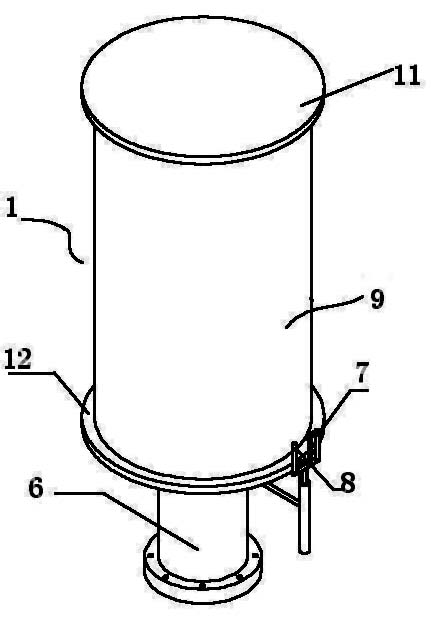

[0041] The difference between this embodiment and Embodiment 1 is that the upper end cover 11 is a multi-layer structure, which is a support layer, a fire retardant layer, a diverter plate layer and a combustion layer from bottom to top. The support layer, fire retardant layer of the upper end cover Layer, diverter plate layer and combustion layer have the same material and structure as the support layer 2, fire retardant layer 3, diverter plate layer 4 and combustion layer 5 of the barrel respectively, and are correspondingly manufactured as one. That is to say, in this embodiment, the supporting layer 2, the fire-blocking layer 3, the diverter plate layer 4 and the combustion layer 5 of the cylinder body adopt a structure similar to one layer wrapping one layer on the upper side and the side surface, which can increase the combustion area of the combustion layer , which is conducive to improving the combustion efficiency of gas.

[0042] The flame-retardant low-concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com