Multifunctional leather goods processing workstation

A workstation, multi-functional technology, applied in the direction of leather softening, leather drying, clothing, etc., can solve the problem of high input cost, achieve the effect of low thermal inertia, fast processing speed and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

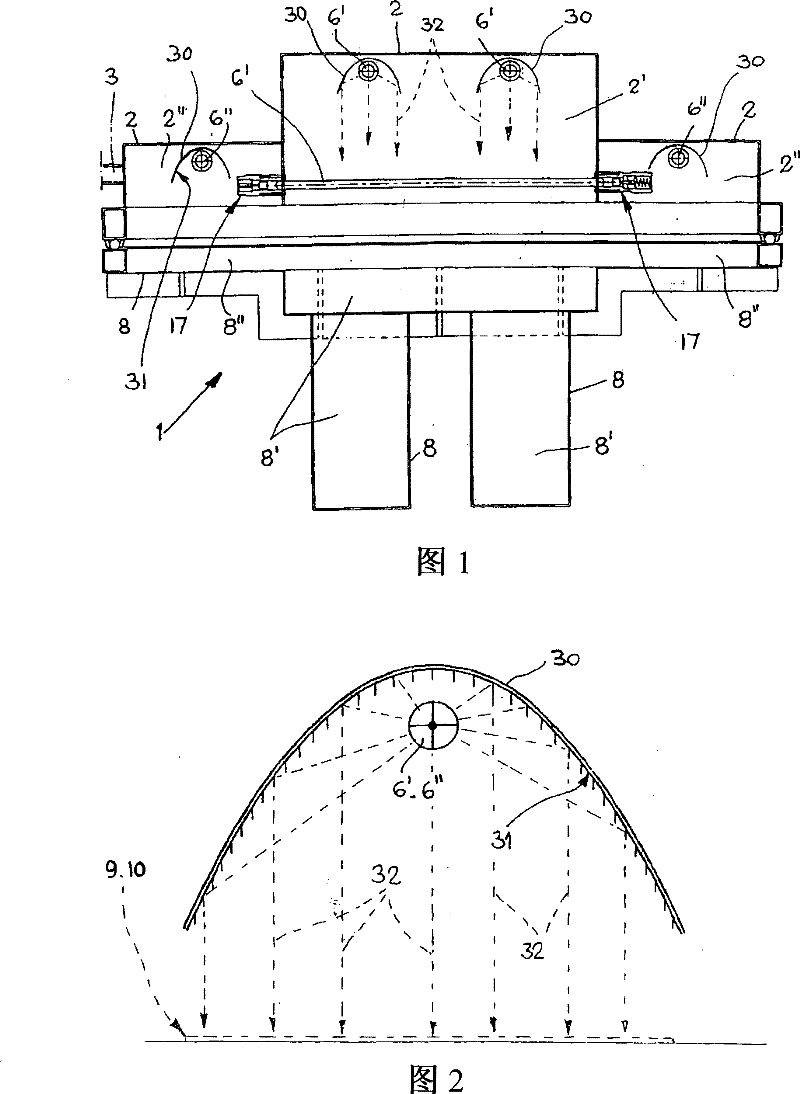

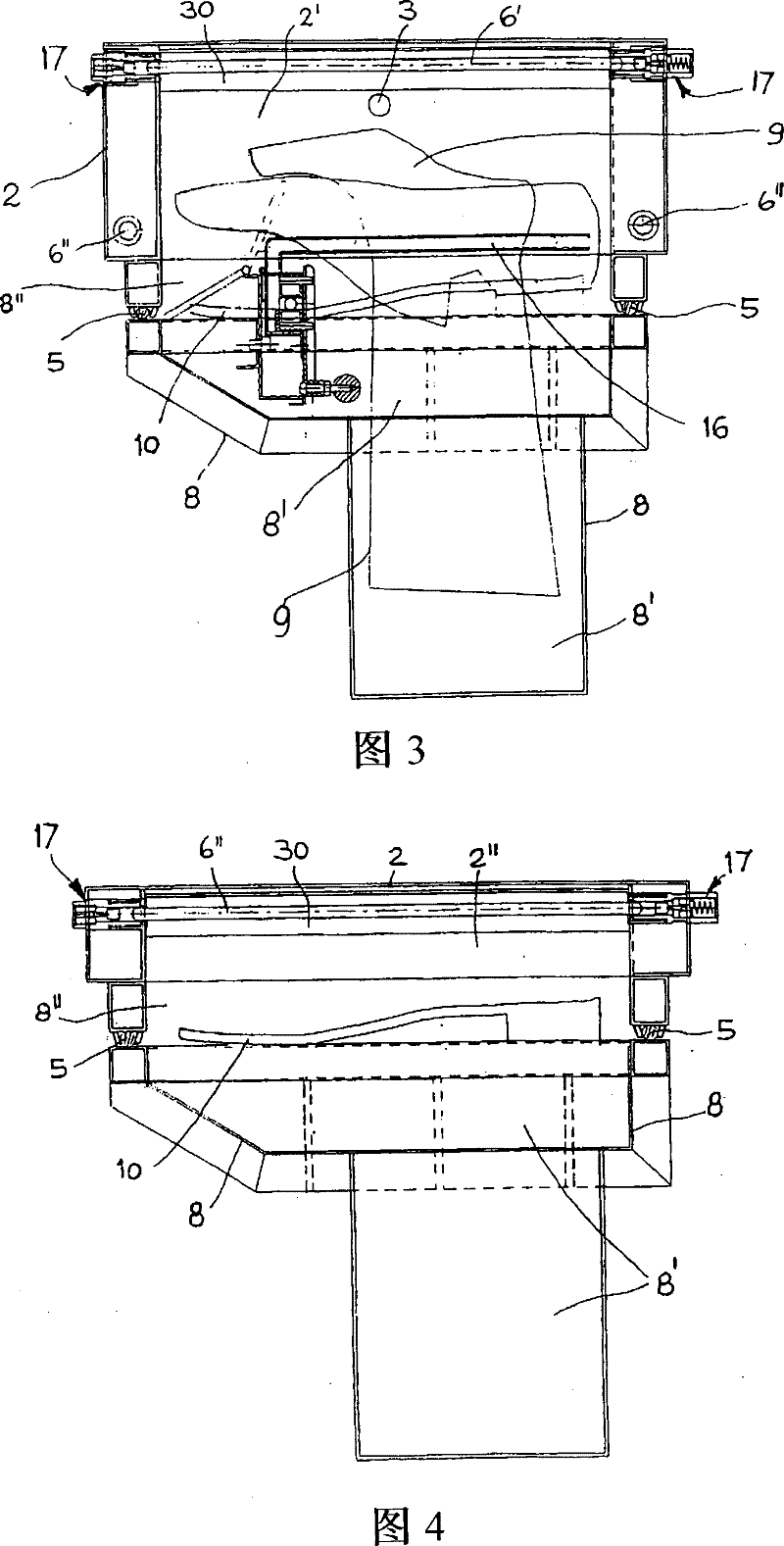

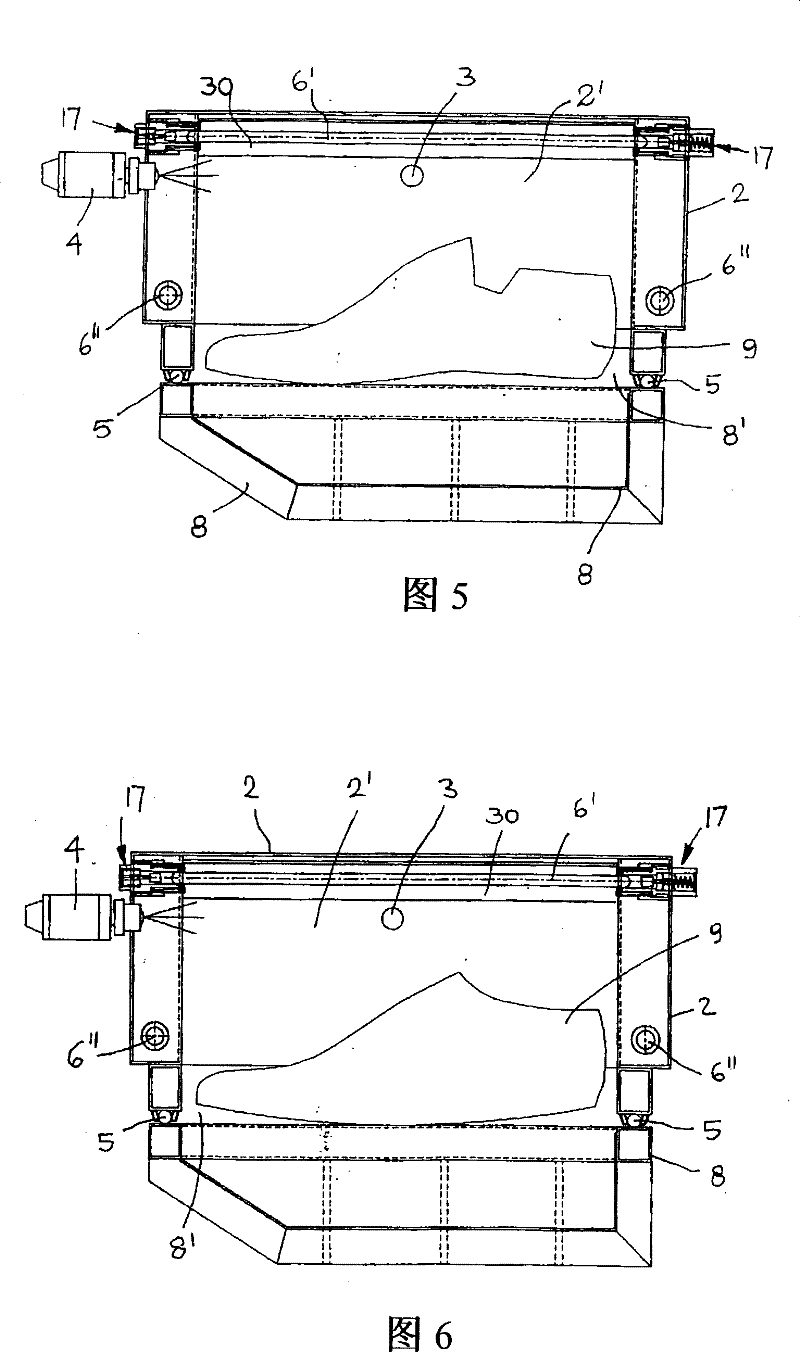

[0022] Please refer to figure 1 , the multifunctional leather processing workstation 1 includes at least one upper casing 2, which has a plurality of chambers 2', 2" connected to a vacuum generating device through at least one suction port 3. Each upper casing 2 is provided with a connecting The interface 4 of the external steam generator. Each chamber 2', 2" is provided with at least one near-infrared radiation type heating lamp 6', 6".

[0023] Each upper casing 2 is preferably, but not necessary, reserved sealing sockets 17 for heating lamp tubes 6 ', 6 "inserted in many different positions, so that according to different processing procedures and / or the shape of the leather goods to be processed , to install different numbers of heating lamps 6', 6" and / or arrange them in different positions.

[0024] Please refer to figure 2 , each near-infrared radiation type heating lamp tube 6', 6 "middle-section light-emitting part, in its face leather goods 9, 10 (see image 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com