Electromagnetic steam self-circulation air heating device

A heating device and self-circulation technology, applied in air heaters, lighting and heating equipment, fluid heaters, etc., can solve the problems of large occupation area, low surface temperature of radiators, and many materials used, so as to reduce the overall structure and materials, reducing radiator area, reducing energy consumption and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

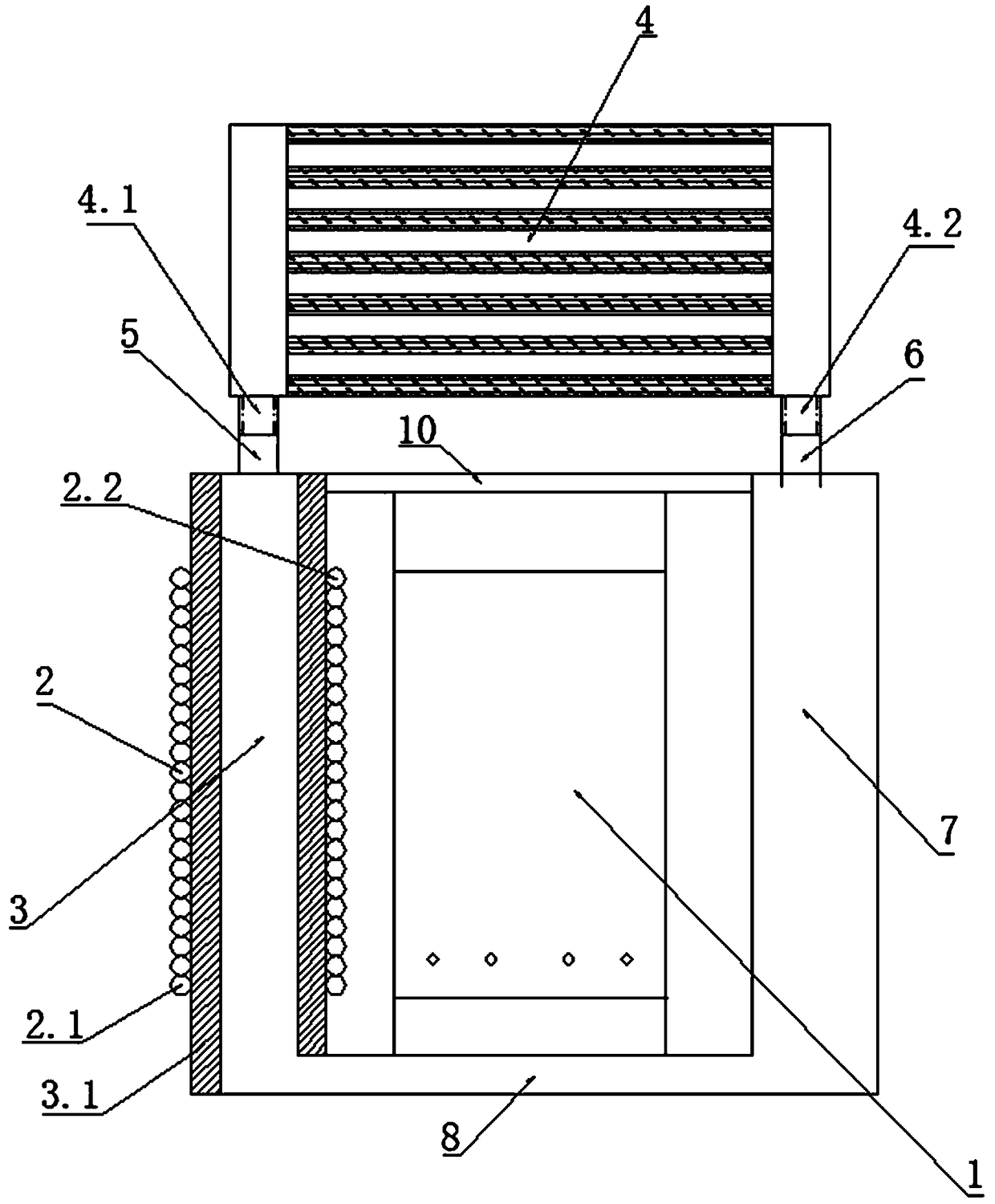

Embodiment 1

[0025] The invention proposes an electromagnetic steam self-circulating warm air device, which solves the shortcomings of water heating and warm air. The electromagnetic heating device is used to generate atmospheric pressure steam. The water in the return pipe is condensed into water and returned to the water storage tank. The water in the water storage tank is sent to the electromagnetic eddy current heating unit through the water supply pipe to generate steam; the natural circulation is realized through heating evaporation, exothermic condensation, and backflow water supply, and continuous heating , release heat, and realize heating. In this process, the circulating pump is canceled, the heating auxiliary energy consumption is reduced, the area of the radiator is reduced, the copper, aluminum and steel used in the radiator are saved, and there is no noise generated by the water pump, such as figure 1 , figure 2 As shown, the following arrangement structure is adopted in...

Embodiment 2

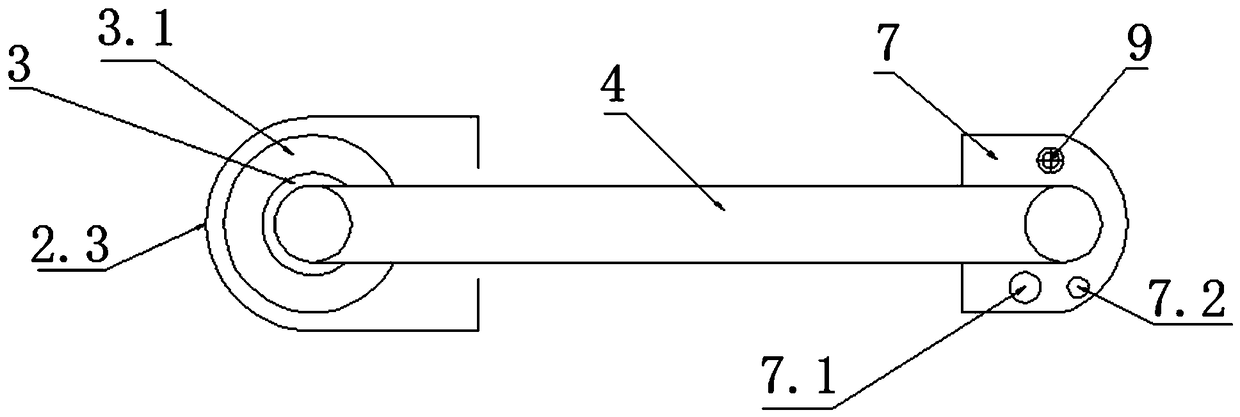

[0028] This embodiment is further optimized on the basis of the above-mentioned embodiments, such as Figure 1~2 As shown, further in order to better realize the present invention, the following arrangement structure is adopted in particular: the electromagnetic eddy current heating unit includes at least one control unit 1, a group of electromagnetic coils 2 and a heating chamber 3, and the electromagnetic coil 2 covers Set on the heating cavity 3, the control unit is connected with the control electromagnetic coil 2.

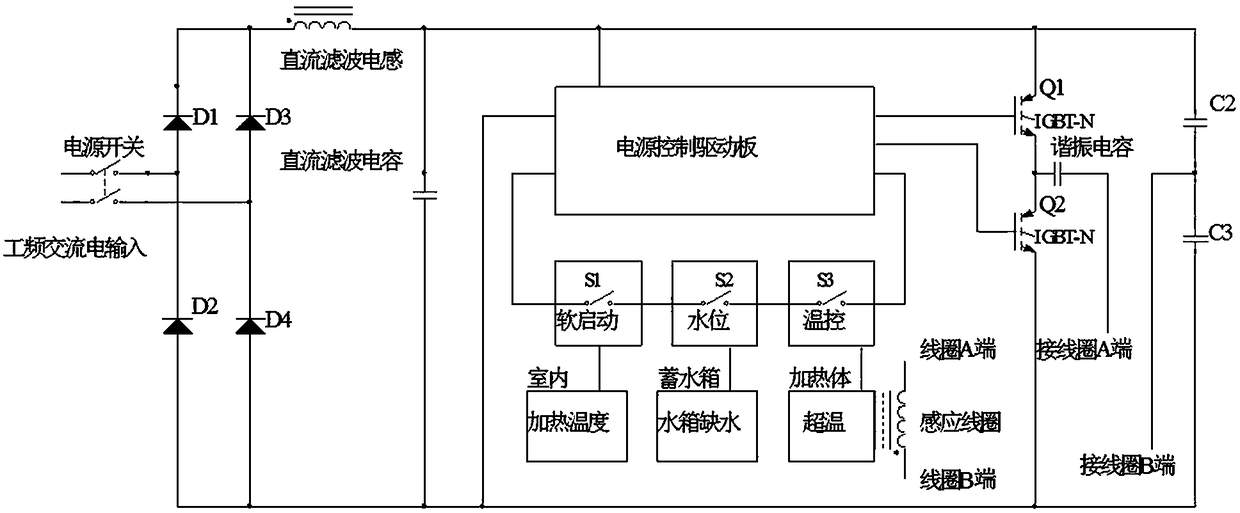

[0029] When setting, the preferred setting scheme is: the electromagnetic eddy current heating unit is provided with at least one control unit 1, a group of electromagnetic coils 2 and a heating chamber 3; The power supply and the electromagnetic coil 2, the power supply provides working power for the electromagnetic coil 2 under the control of the control unit 1; Preferably 15-50KHz) through the two ends of the electromagnetic coil 2 (coil A terminal 2.1 and...

Embodiment 3

[0036] This embodiment is further optimized on the basis of any of the above embodiments, further to better realize the present invention, such as Figure 1~2 As shown, the following arrangement structure is particularly adopted: the warm air radiator 4 is arranged above the heating chamber 3 and the water storage tank 7 .

[0037] As a preferred arrangement, the warm air radiator 4 is arranged above the heating chamber 3 and the water storage tank 7, and the inlet 4.1 of the warm air radiator 4 is connected to the upper end of the heating chamber 3 through a steam throttling pipe 5, and The steam throttling pipe 5 and the inlet 4.1 are connected by various connection methods such as screw connection, welding or clamping, and the steam throttling pipe 5 and the heating chamber 3 are connected by welding or auxiliary pipe connection or other connection methods; The outlet 4.2 of the warm air radiator 4 is connected to the upper end of the water storage tank 7 through the return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com