Method for producing metal foams and furnace for producing same

A metal and melting furnace technology, applied in the field of melting furnaces for manufacturing the metal foam material, can solve the problems of increased production cost, dealing with danger, etc., and achieves the effect of easy handling and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

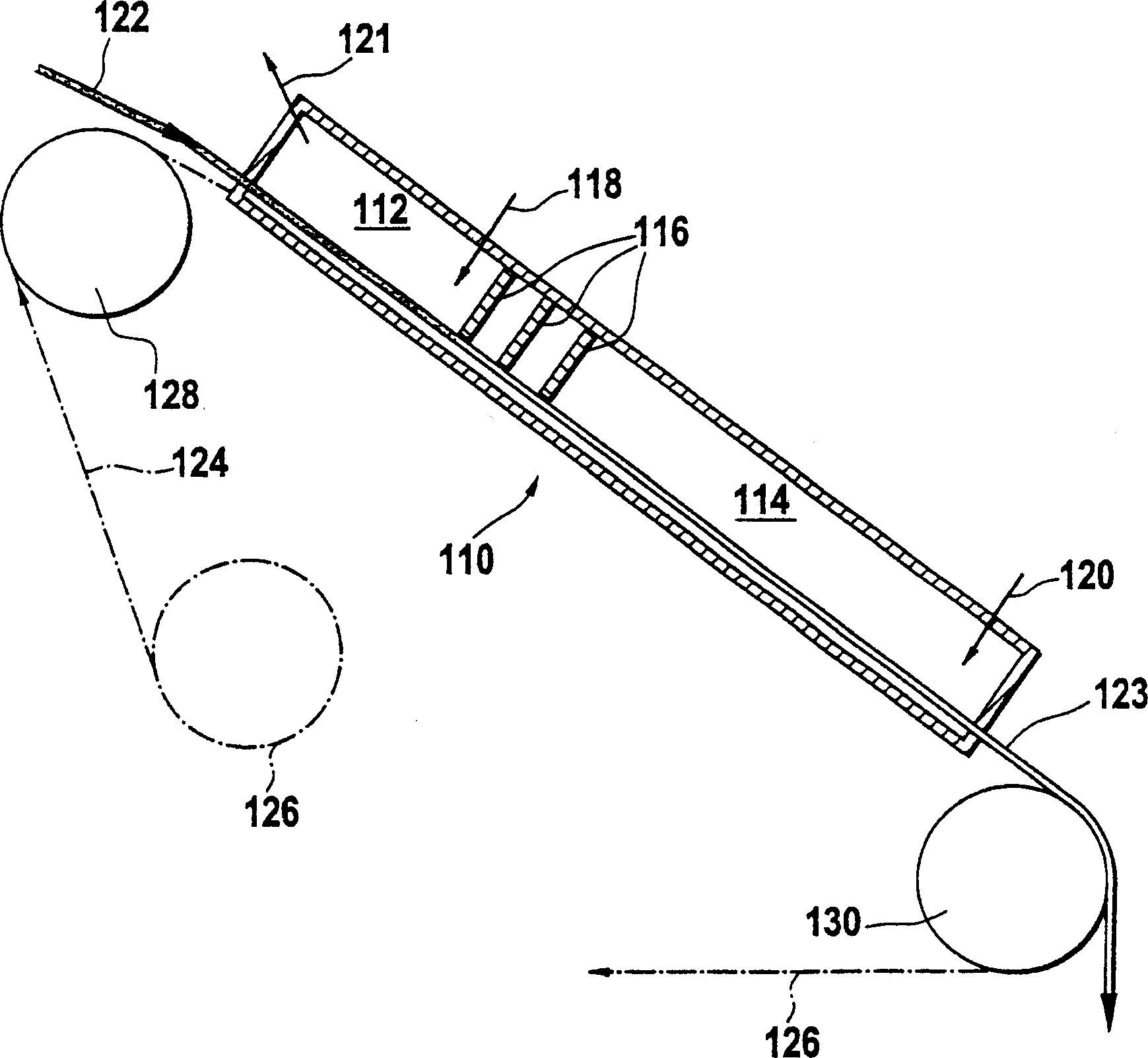

[0063] As with the first embodiment, the copper-clad polymeric substrate 122 is advanced within the furnace due to the rotation of two rollers 128 and 130 . However, it must be noted that the pulling force is not applied to the copper-clad substrate 122 , but to the copper foil 124 . And it is obvious that the copper-clad polymer substrate 122 is not in contact with the furnace plate because it is placed on the copper foil 124 . The copper-clad polymer substrate is therefore protected from damage, tearing or deformation as it travels through the furnace 110 .

[0064] From a thermal point of view, copper foil is more advantageous than conveyor belts. Indeed, a conveyor belt generally has 10 to 15kg / m 2 Surface mass density between , while the surface mass density of suitable copper foil may be in the range of 100 to 200g / m 2 between. Therefore, the thermal inertia of the copper foil is much lower than that of the conveyor belt, and the heating rate is much faster, so the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com