Platinum thermal resistance temp. sensor

A temperature sensor, platinum thermal resistance technology, used in thermometers, thermometers and instruments with directly sensitive electrical/magnetic components, etc., can solve the problems of corrosion resistance, volume increase, thermal inertia and measurement accuracy, and reduce Production cost, product life extension, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

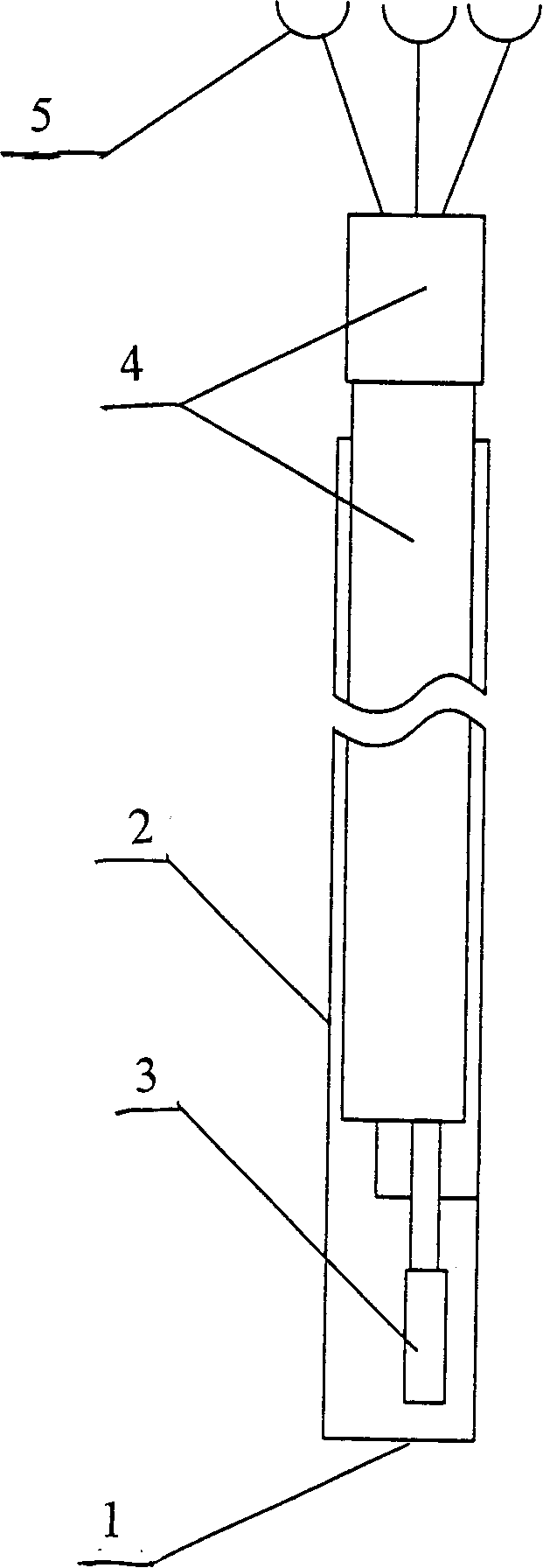

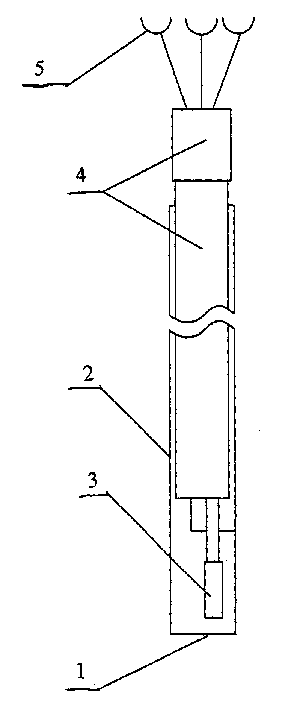

[0017] From figure 1 It can be seen that the present invention is composed of a polytetrafluoroethylene sleeve 2, a platinum thermal resistance 3, a heat shrinkable tube 4, and a lug 5; wherein the platinum thermal resistance 3 is connected to the lug 5 through the heat shrinkable tube 4 through a wire, and the platinum thermal resistance Resistor 3, wire and heat shrinkable tube 4 are covered with polytetrafluoroethylene sleeve 2, platinum thermal resistance 3 is close to the tube wall of polytetrafluoroethylene sleeve 2 and the inner wall of PTFE sleeve bottom cover 1, heat shrinkable tube The outer wall of 4 is socketed with the tube wall of polytetrafluoroethylene sleeve 2.

[0018] The key process of the present invention is the welding back cover of the polytetrafluoroethylene casing, which requires absolutely tight and no gaps at the welding place, and it can perform temperature measurement operations in corrosive liquids or gases exceeding 250 degrees Celsius under nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com