De-icing and/or anti-icing system for the leading edge of an aircraft wing

a leading edge and aircraft technology, applied in the direction of electrical equipment, power plant arrangements/mountings, heating element shapes, etc., can solve the problems of reducing the performance of the aircraft's engine, and affecting the performance of the aircraft. achieve the effect of keeping the temperature substantially constan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]In the following, the system according to the invention will be described when it is integrated with an air intake lip of an aircraft engine.

[0039]It must, however, be remembered that the invention can also apply to a leading edge of an aircraft wing.

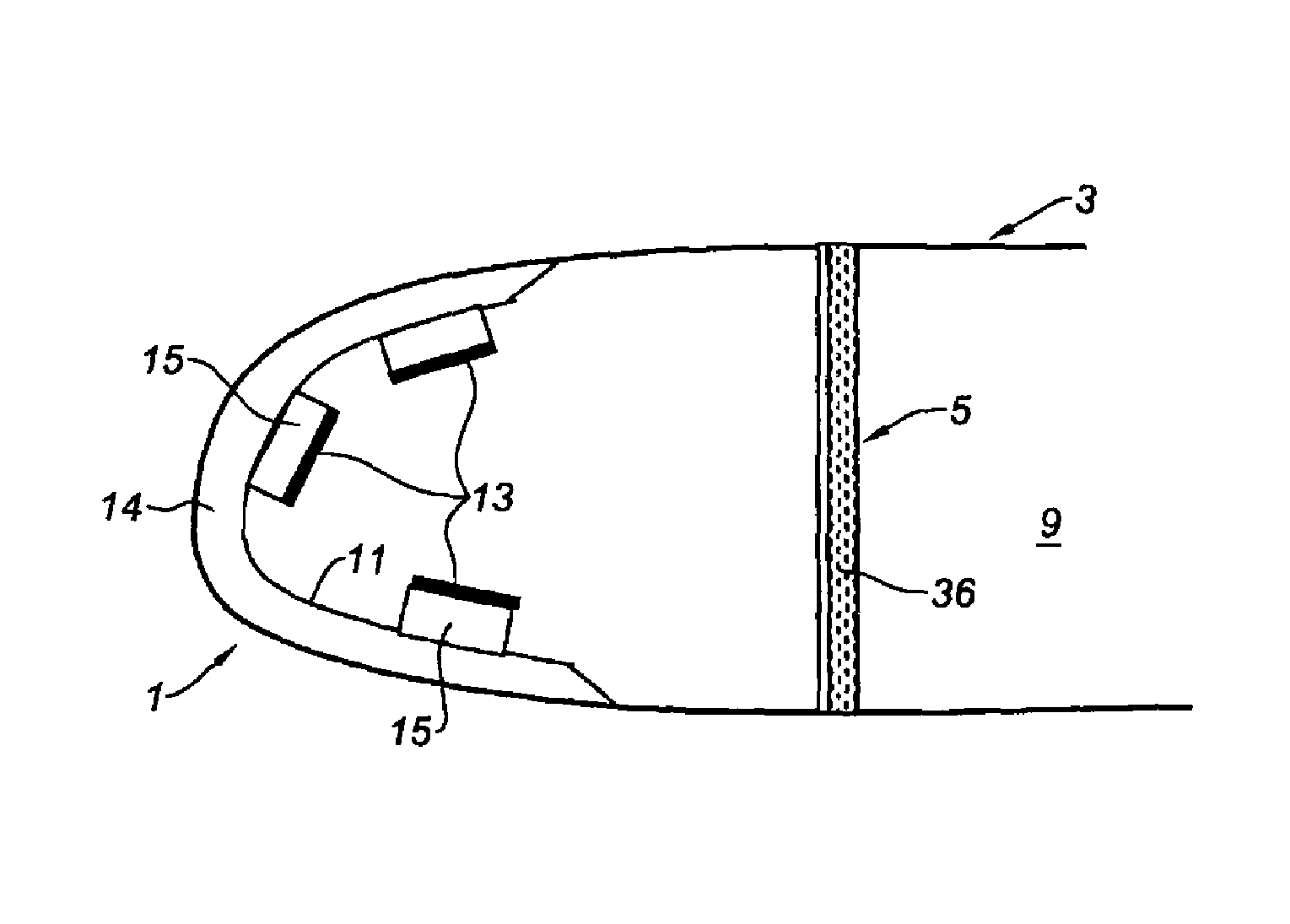

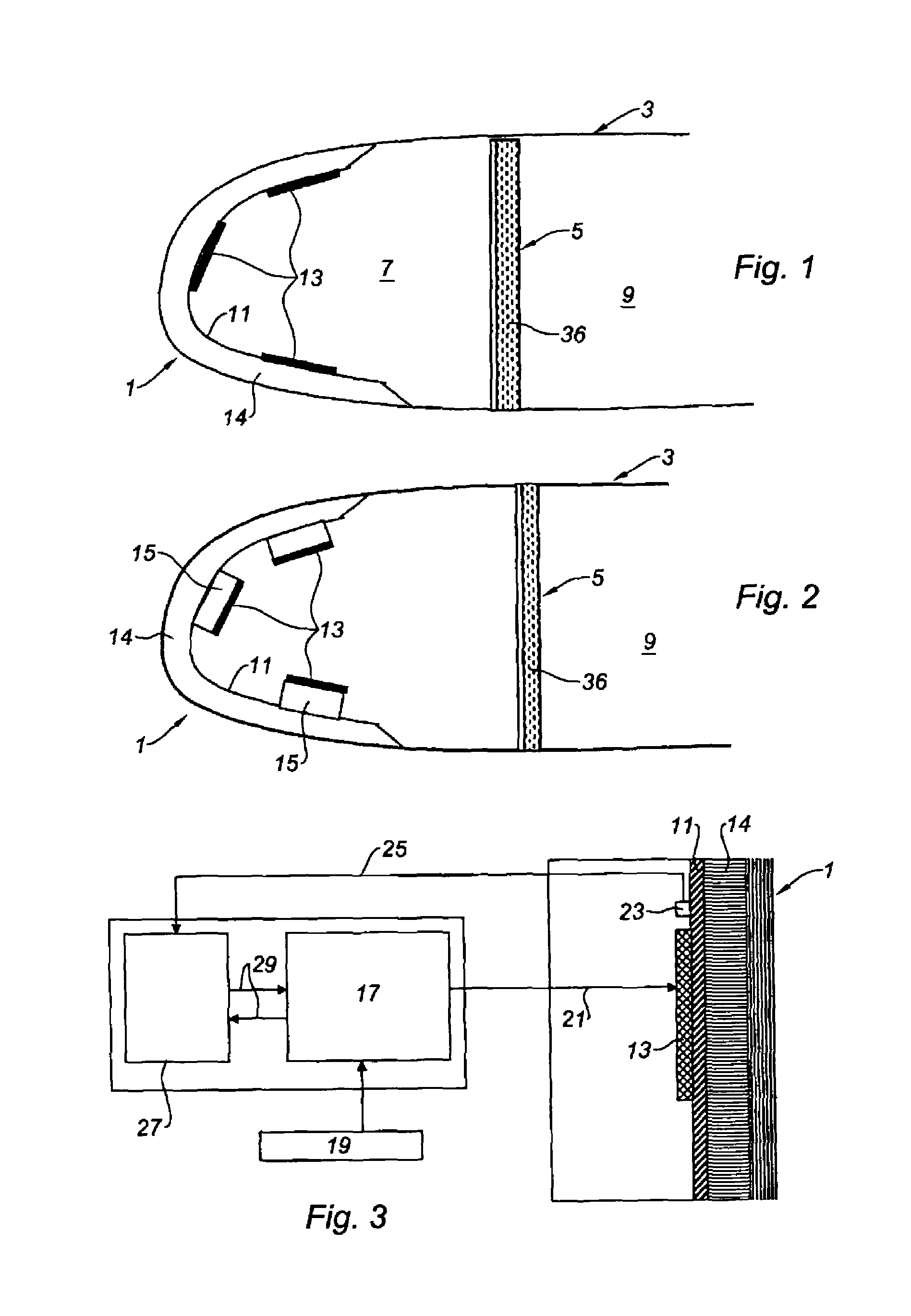

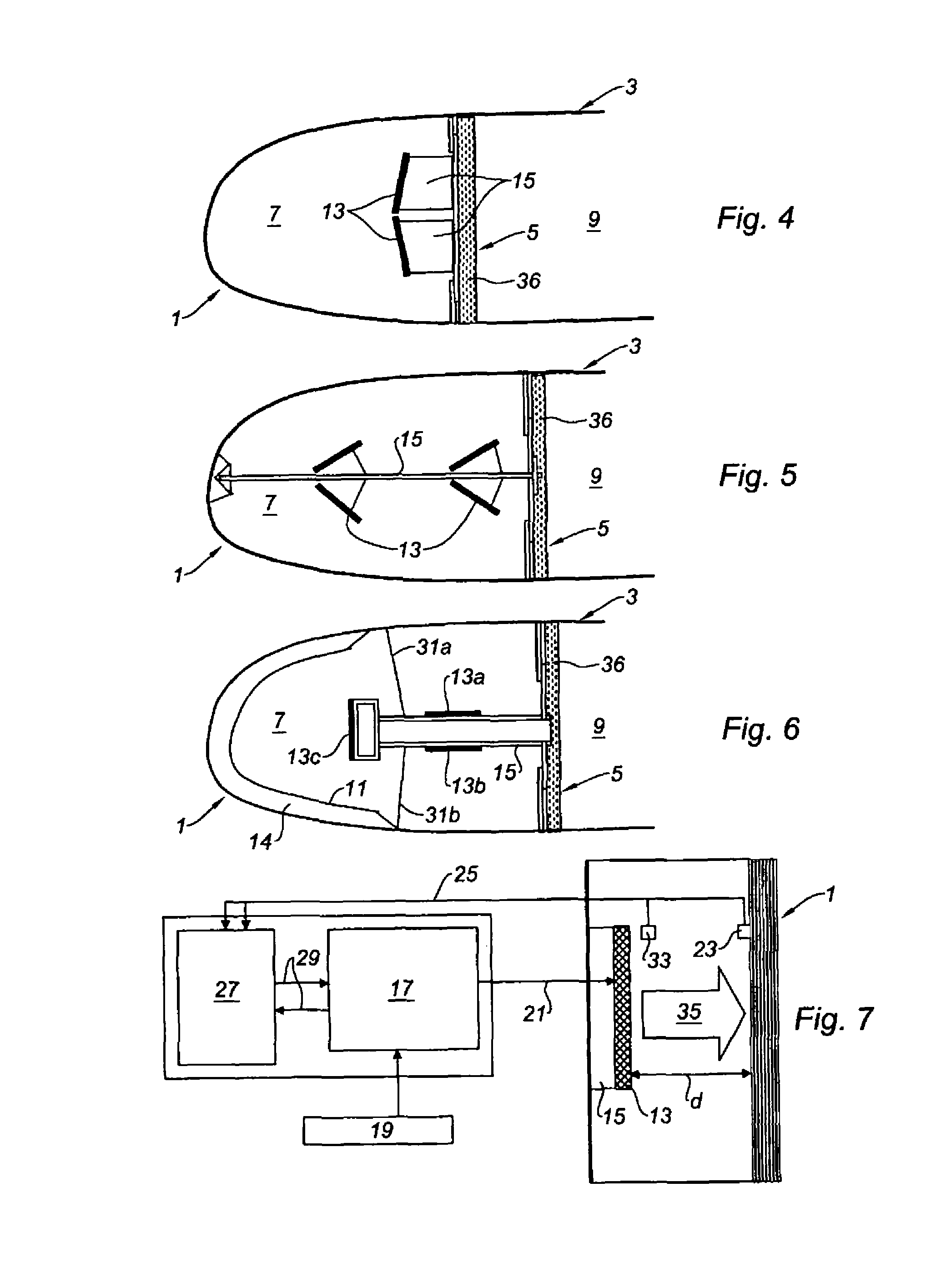

[0040]We will now refer to FIG. 1, which shows an air intake 3 lip 1 of the aircraft engine.

[0041]As known in itself, the air intake of an aircraft engine, which is part of the nacelle surrounding said engine, is a sort of substantially annular shroud making it possible to capture outside air and orient it toward the fan, then toward the compressor of the aircraft engine.

[0042]The lip 1 of this air intake 3 is the leading edge thereof in a way, i.e. the edge that separates the stream of air entering the engine from that flowing toward the outside of the nacelle.

[0043]As known in itself, the air intake 3 generally comprises a partition 5 called “front partition” separating the cavity 7 defined by the lip 1 from the rest of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com