Pyrolysis gasification furnace

A pyrolysis gasification and furnace body technology, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve problems such as energy consumption, land waste, and environmental pollution, and achieve improved combustion effects, increased safety, and improved The effect of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

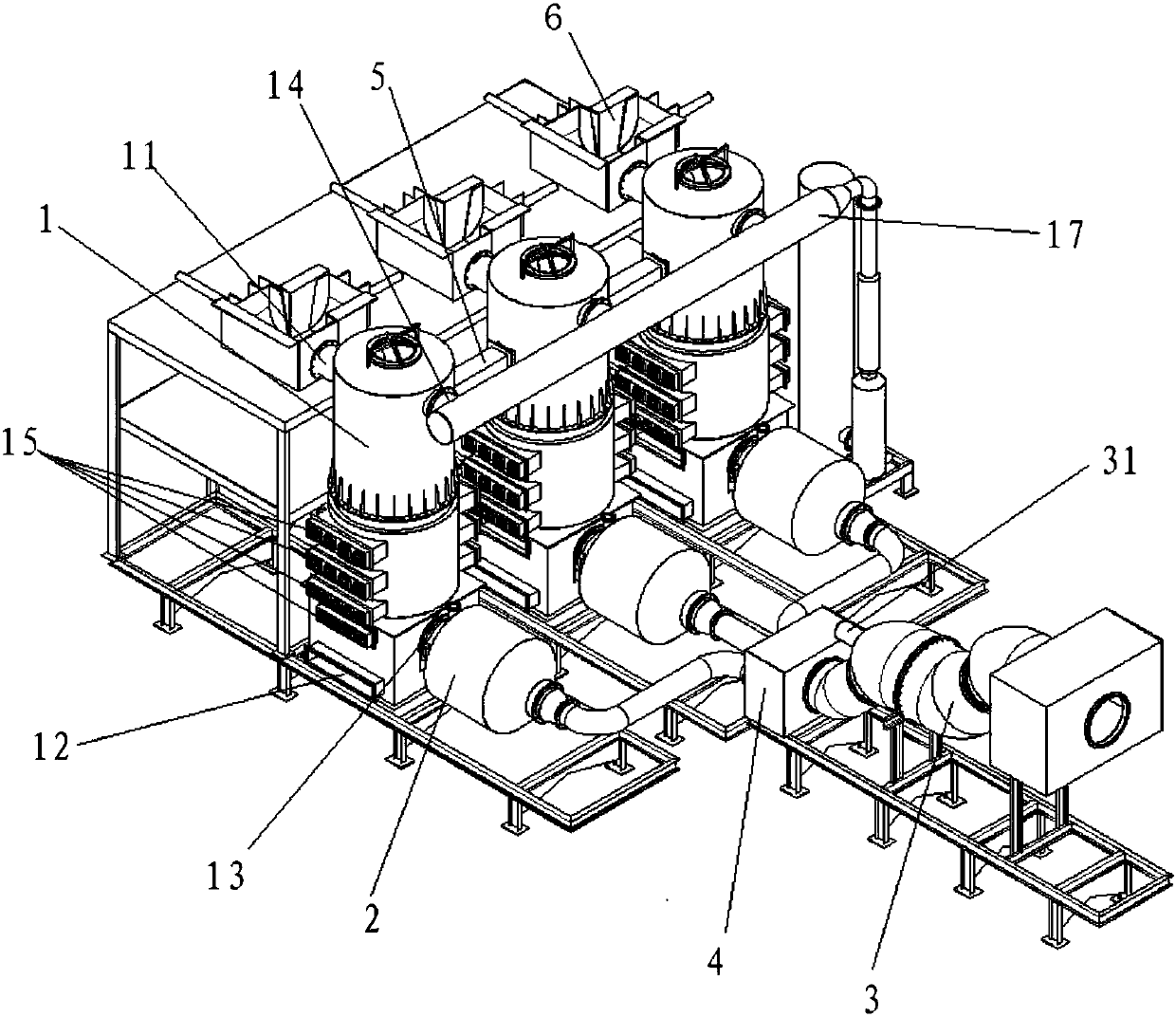

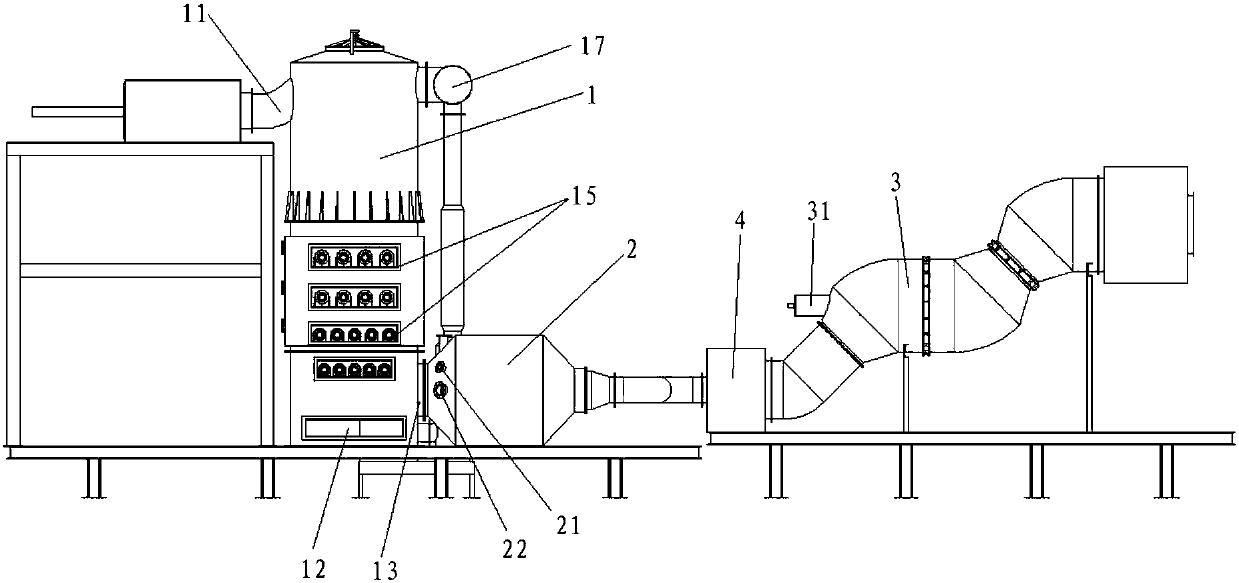

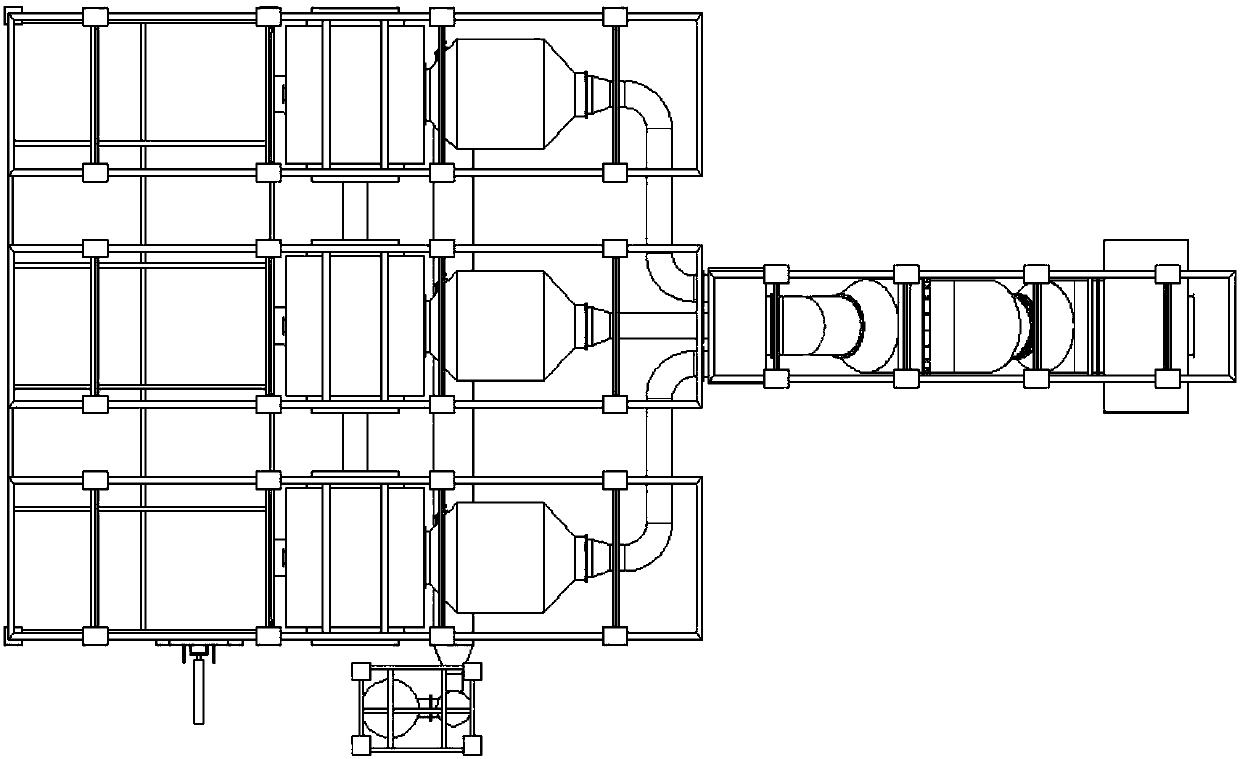

[0030] Refer to attached Figures 1 to 4 As shown, the pyrolysis gasification furnace of the present invention includes a furnace body 1 , a combustion chamber 2 and a rapid cooling tube 3 .

[0031] The furnace body 1 is a sealable chamber with a feed inlet 11 on its upper part, a slag discharge port 12 and an exhaust port 13 on its lower part, and an air inlet for feeding auxiliary gas on the side wall of the furnace body 1. . The feeding port 11 is connected with the hydraulic closed continuous feeding system 6 . This body of heater 1 inside is provided with four-layer fire grate 15, then this fire grate 15 is divided into four combustion chambers by body of heater 15, and the body of heater side wall of each combustion chamber is all provided with air inlet, and organic waste is discharged from the upper part. The feed port 11 enters the uppermost combustion chamber after being sealed and fed through the hydraulic closed continuous feeding system 6, where the organic mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com