A kind of oil sludge modifier and method for converting oil sludge into regenerated solid fuel by modifying the same

A solid fuel and modifier technology, applied in solid fuel, sludge treatment, chemical instruments and methods, etc., can solve the problems of high treatment cost, limited treatment capacity, secondary pollution, etc., and achieve simple preparation process and high combustion performance Good, high burnout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

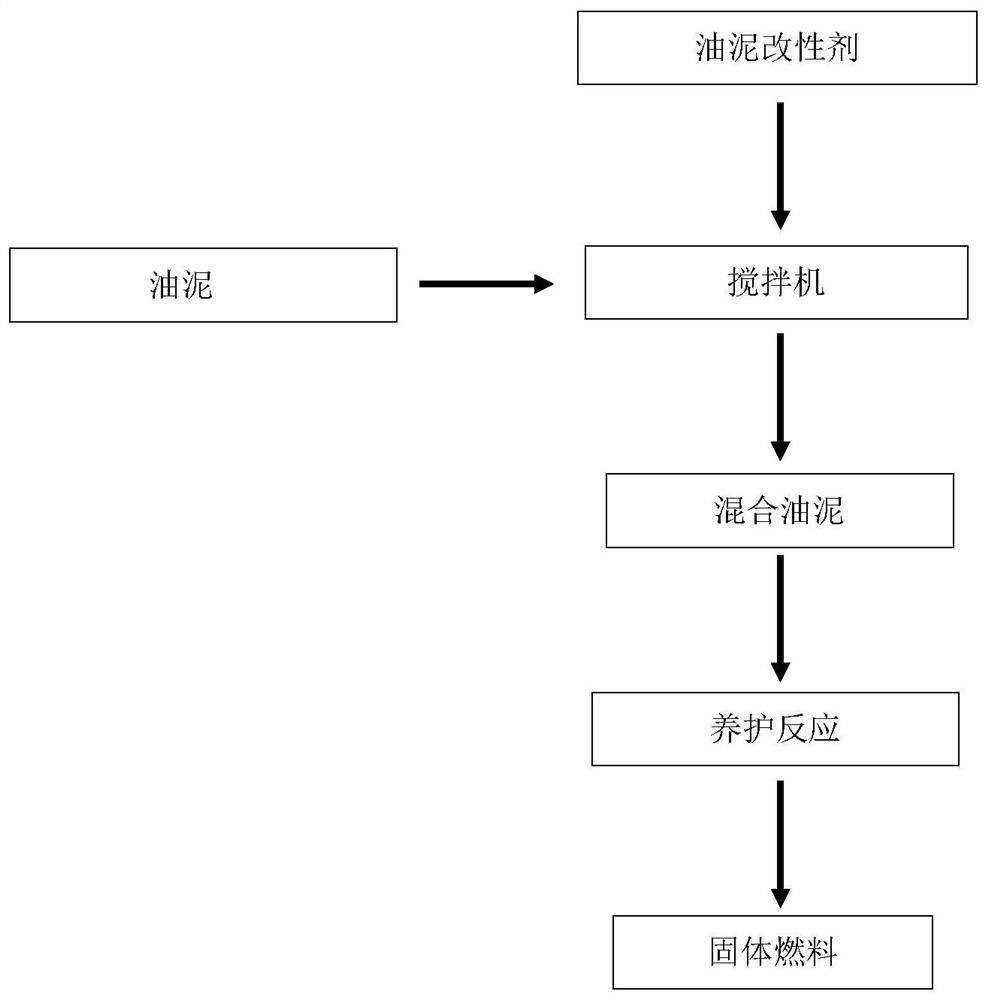

Method used

Image

Examples

Embodiment 1

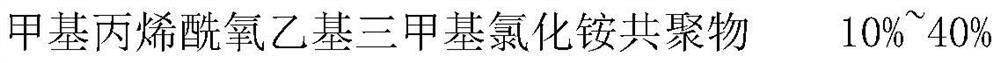

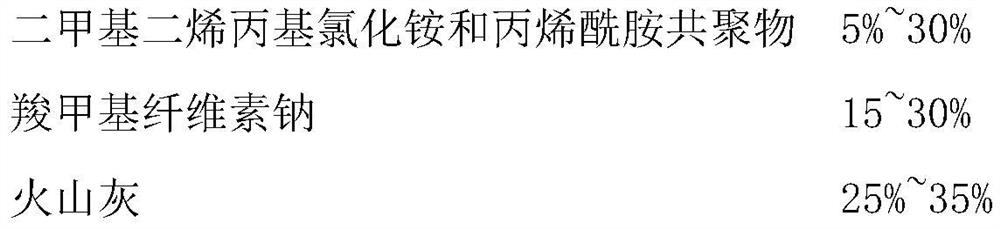

[0028] The sludge modifier of this embodiment is composed of methacryloxyethyltrimethylammonium chloride copolymer, dimethyldiallylammonium chloride and acrylamide copolymer, sodium carboxymethylcellulose, pozzolan The mass percentage 10%:30%:30%:30% is evenly mixed.

Embodiment 2

[0030] The sludge modifier of this embodiment is composed of methacryloxyethyl trimethyl ammonium chloride copolymer, dimethyl diallyl ammonium chloride and acrylamide copolymer, sodium carboxymethyl cellulose, pozzolan press The mass percentage 30%:20%:25%:25% is evenly mixed.

Embodiment 3

[0032] The sludge modifier of this embodiment is composed of methacryloxyethyl trimethyl ammonium chloride copolymer, dimethyl diallyl ammonium chloride and acrylamide copolymer, sodium carboxymethyl cellulose, pozzolan press The mass percentage 40%: 15%: 10%: 35% is mixed uniformly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com