Continuous heat accumulating type heat exchanger

A technology of heat exchanger and heat storage type, which is applied in the direction of heat storage heat exchanger, heat exchanger type, indirect heat exchanger, etc., to achieve the effects of strong adaptability, fuel saving, and reduction of emission concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

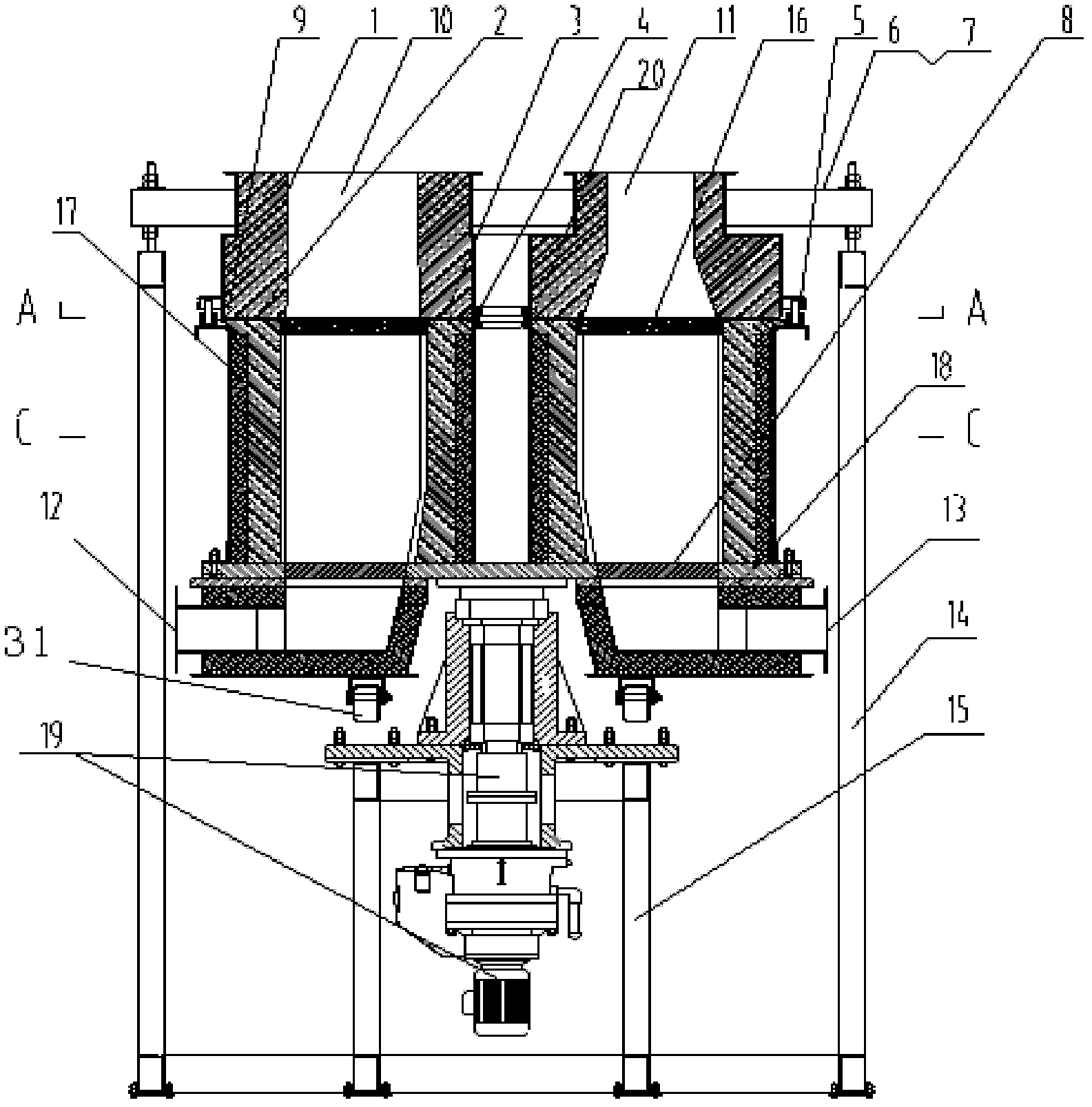

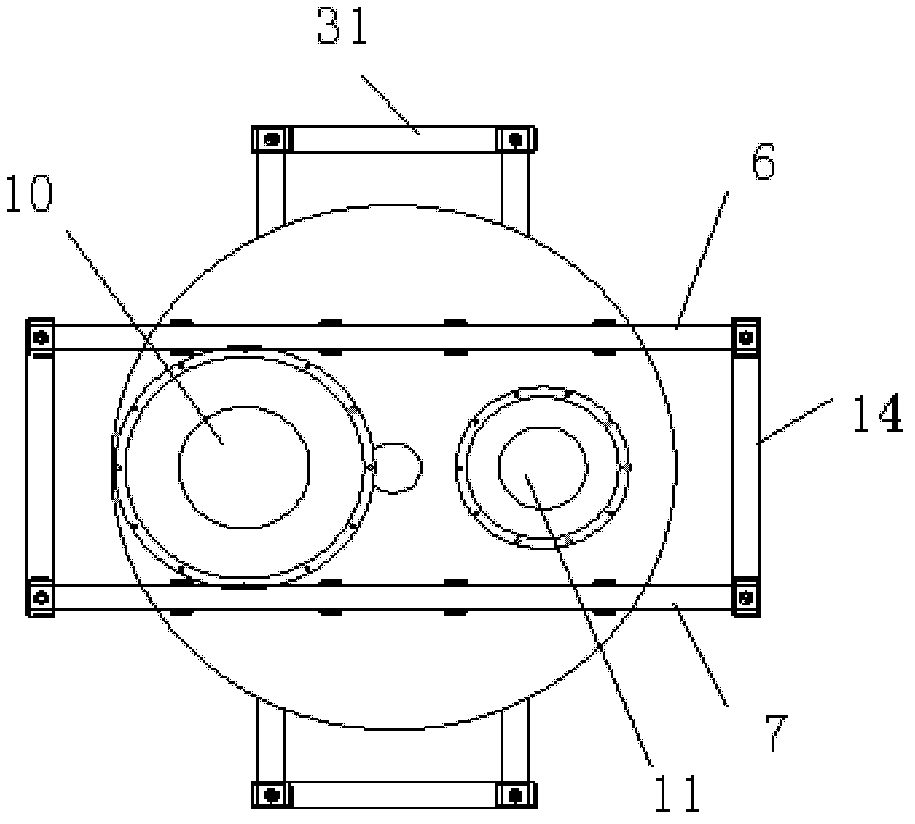

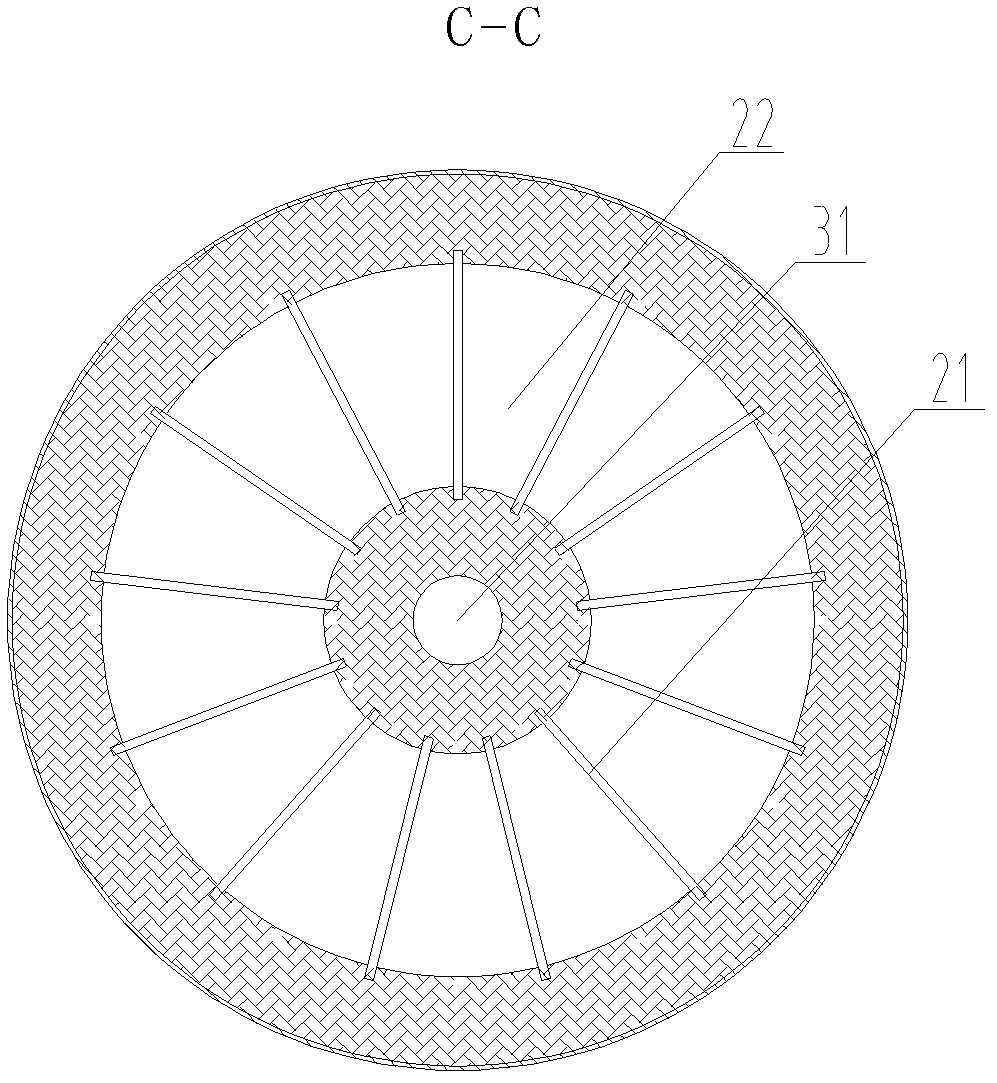

[0031] The present invention will be further described below in conjunction with accompanying drawing.

[0032] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9, the whole is a vertical arrangement, the cross section of the cylinder 17 is an annular hollow 22, the supporting plate 8 is fixed on the lower end of the cylinder 17 with bolts, the supporting plate 8 has a groove 28, and is connected with the middle hollow 31 of the cylinder 17 There are air holes 27 on the corresponding part. During the working state, the cavity is vacated in the middle, and the convective air from bottom to top can cool the balance of the lower part and the transmission device naturally; A uniform plate 21 with thirteen channels, among the thirteen channels, 4 flue gas channels, 3 air channels, 6 transition areas, and are symmetrically arranged, and the thirteen channels are filled with heat storage bodies , the regenerator adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com