Horizontal heat accumulating type efficient heat exchanger

A technology of heat exchanger and heat storage type, which is applied in the direction of heat storage equipment, heat exchanger type, indirect heat exchanger, etc., to achieve the effects of light weight, reduced emissions, and avoiding cumulative errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

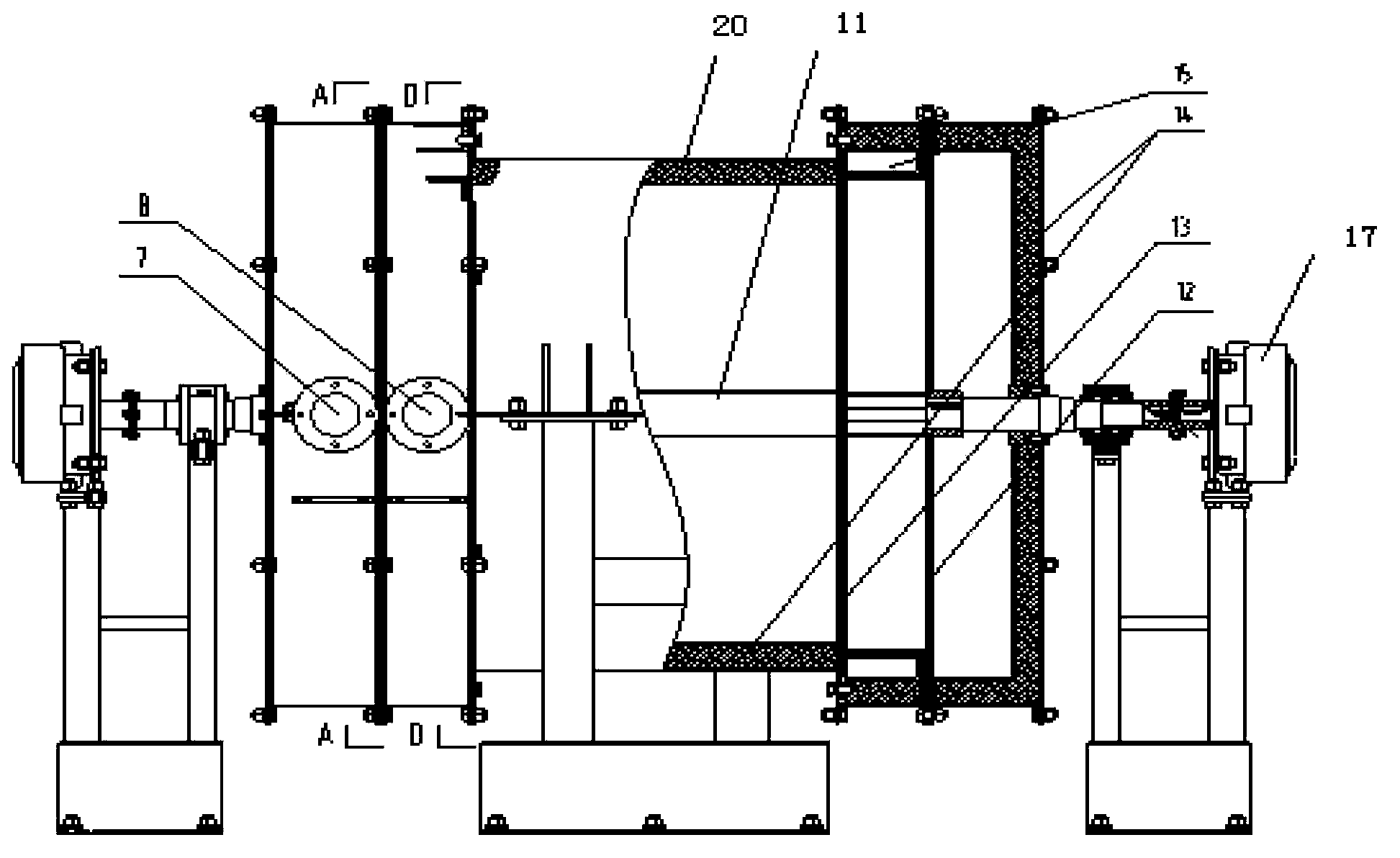

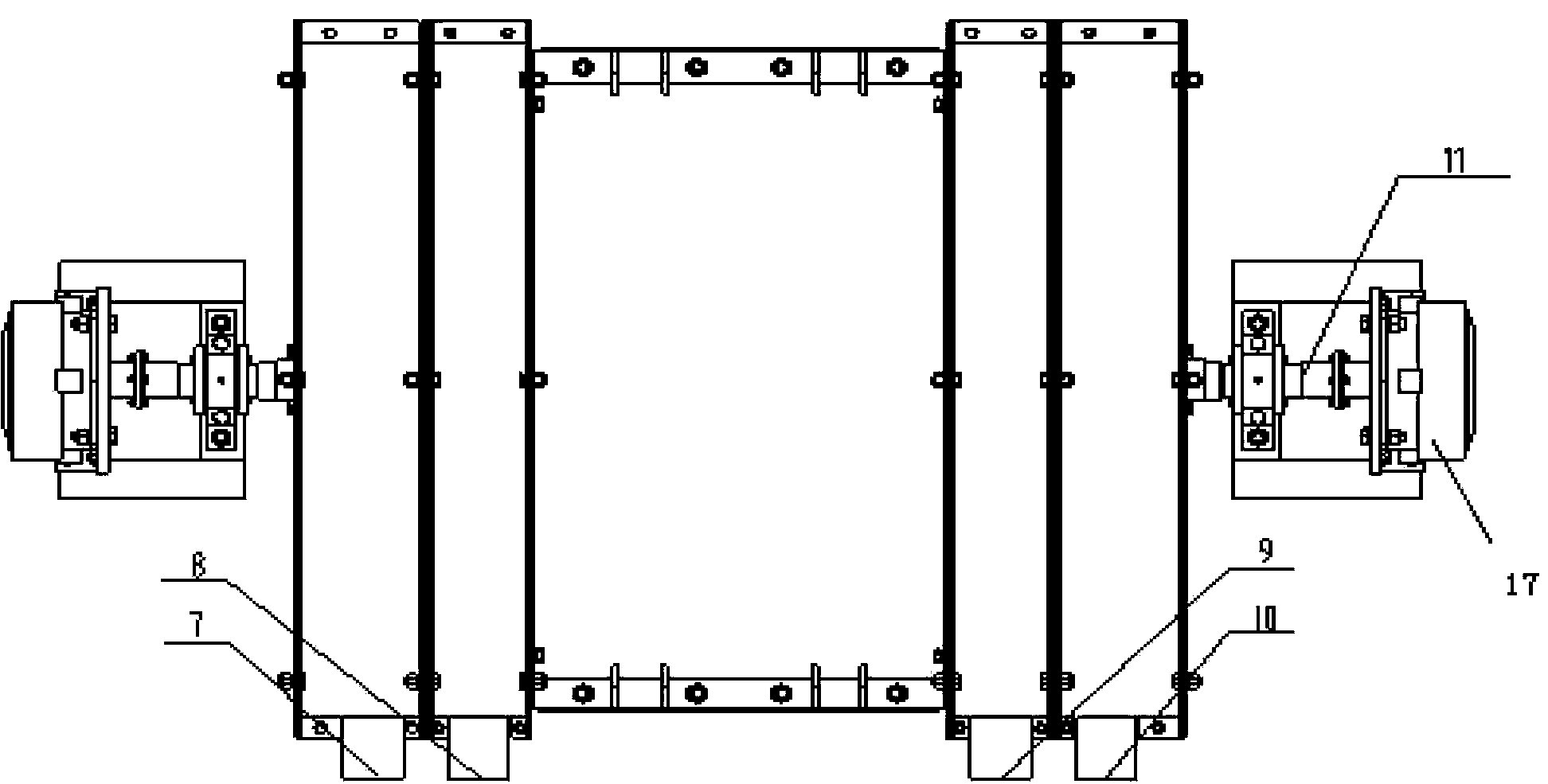

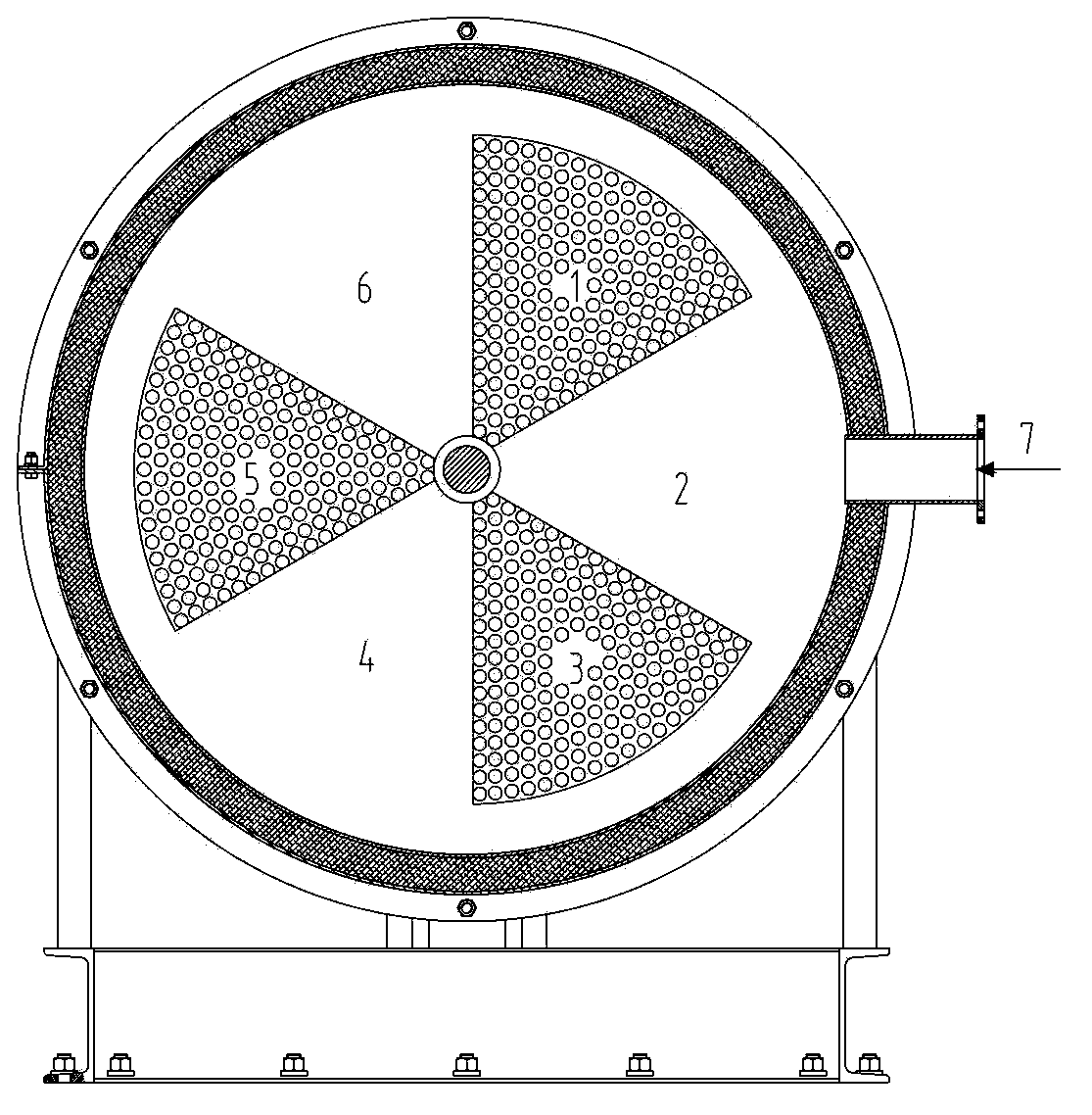

[0033] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7, the inner wall of the horizontal cylindrical shell 20 is provided with a thermal insulation layer 14, and the inside of the horizontal cylindrical shell 20 is divided into six equal axial cavities by partitions: the first cavity 1, the second cavity 2. The third chamber 3, the fourth chamber 4, the fifth chamber 5 and the sixth chamber 6, all of the axial chambers are filled with heat storage bodies, and the two ends of the axial chambers are provided with perforated baffles 13 is used to fix the regenerator. The regenerator is divided into: ceramic ball 21 and ceramic honeycomb body 18 according to different flue gas qualities. The perforated baffle 13 is fixed with the horizontal cylindrical shell 20 by bolts, which is easy to disassemble . One end of the horizontal cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com