Energy-saving shower

A bather and heat energy technology, applied in the field of energy-saving bathers, can solve problems such as troublesome operation and complex structure, and achieve the effects of simple and lightweight structure, high utilization rate of waste heat, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

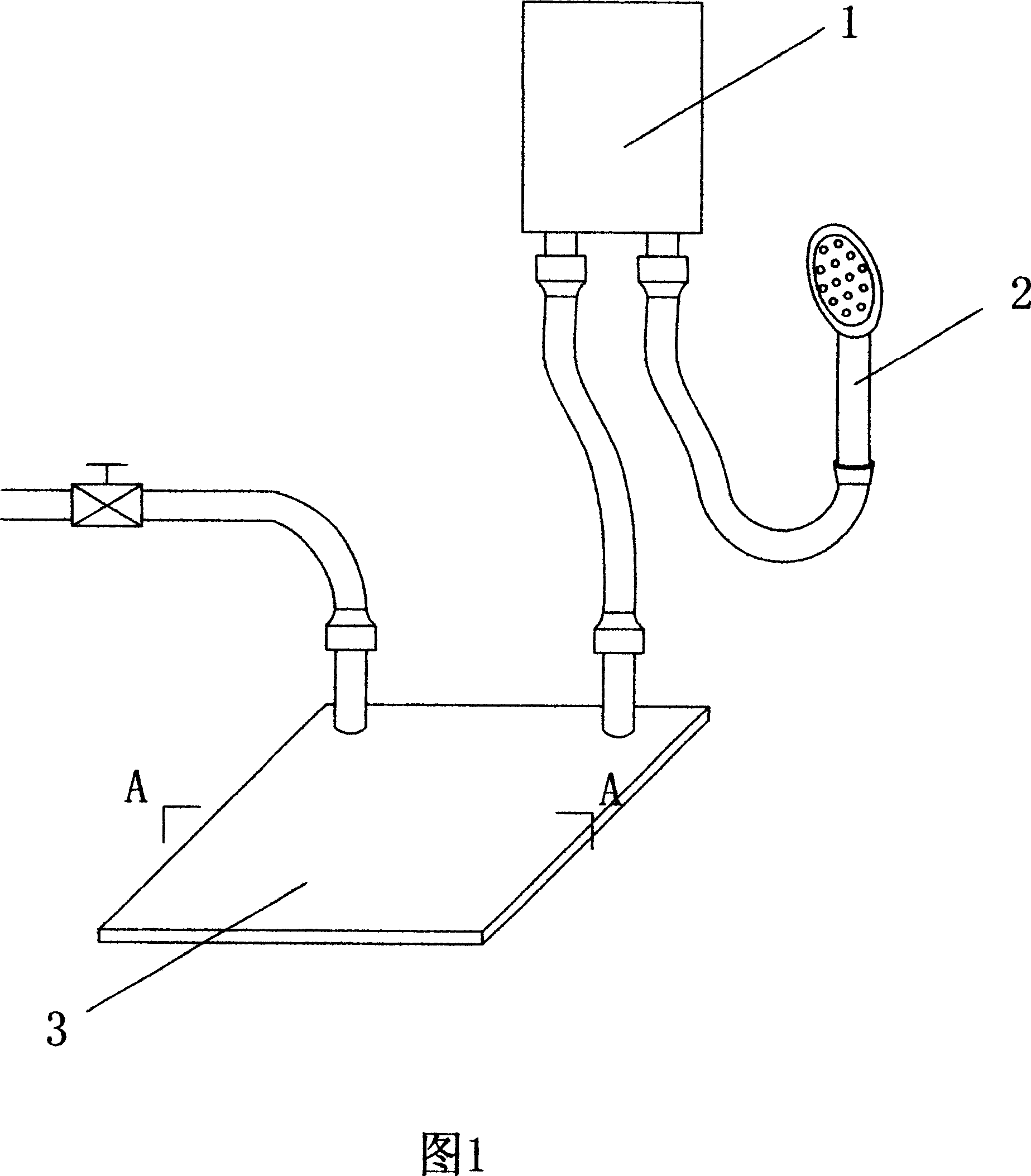

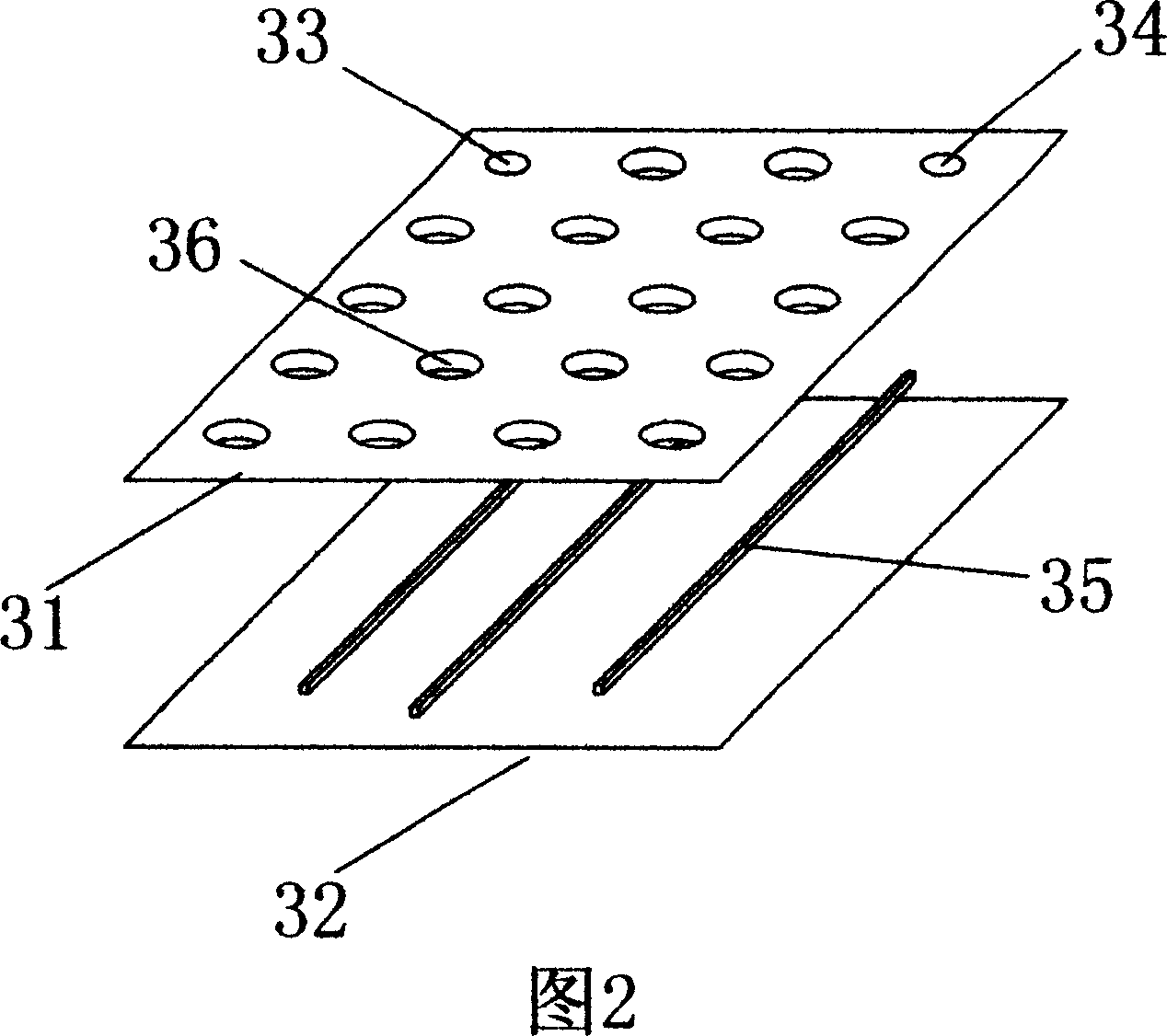

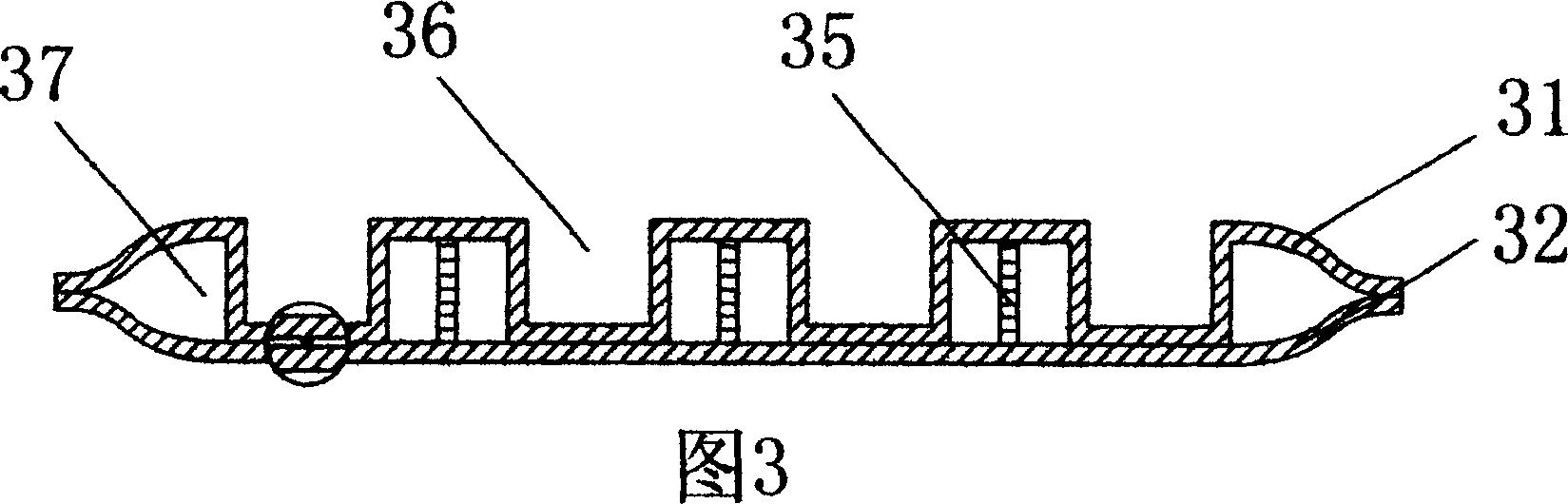

[0019] As shown in FIG. 1 , an energy-saving foam bath includes a water heater 1 , a shower head 2 and a heat transfer device 3 , and the water heater 1 is connected to the shower head 2 and the heat transfer device 3 respectively. As shown in Figures 2, 4 and 6, the thermal energy transmitter 3 is composed of a sealed container, a water inlet port 33 and a water outlet port 34, and the sealed container is provided with an upper panel 31 and a lower bottom plate 32. As shown in Figures 3, 5 and 7, the peripheral seal of the panel 31 and the bottom plate 32 constitutes a hollow layer 37, the water inlet port 33 and the water outlet port 34 are all connected to the hollow layer 37, and the hollow layer 37 is provided with a guide line 35. The upper panel 31 is provided with a groove 36 , and the bottom wall of the groove 36 is welded to the bottom plate 32 .

[0020] As shown in Figure 2, it is the first embodiment of the present invention. The diameter of the groove 36 is 2-10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com