Burning and waste heat power generation system for hazardous wastes

A waste heat power generation and hazardous waste technology, applied in the steam generation method using heat carrier, incinerator, combustion method, etc., can solve the problems of high maintenance cost of refractory bricks, incomplete incineration, high investment cost, etc., and achieve comprehensive utilization of flue gas Effects of waste heat, saving energy consumption and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail, is not to limit the implementation scope of the present invention hereto, and this embodiment does not limit protection scope of the present invention, and those who are familiar with this art will not deviate from the present invention Reasonable changes made under the protection scope and spirit of the invention should all belong to the protection scope of the present invention.

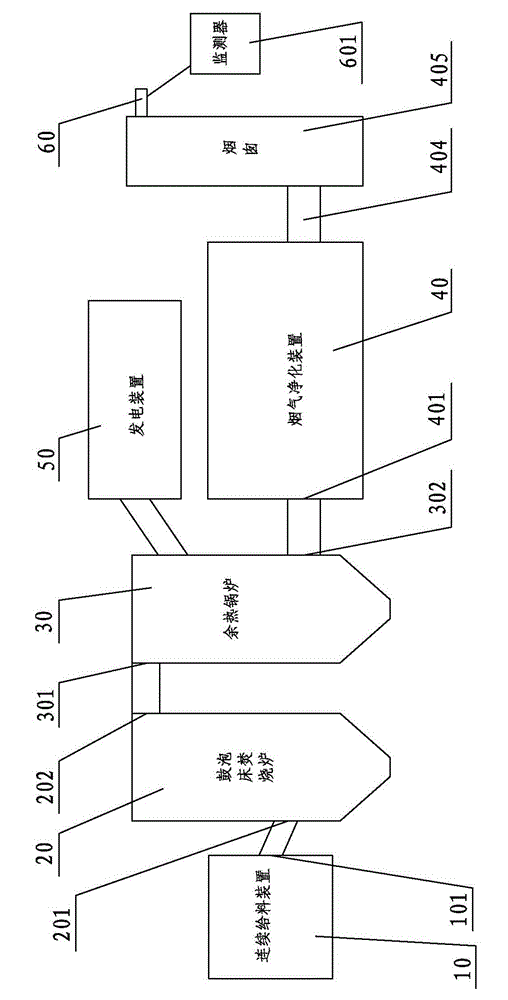

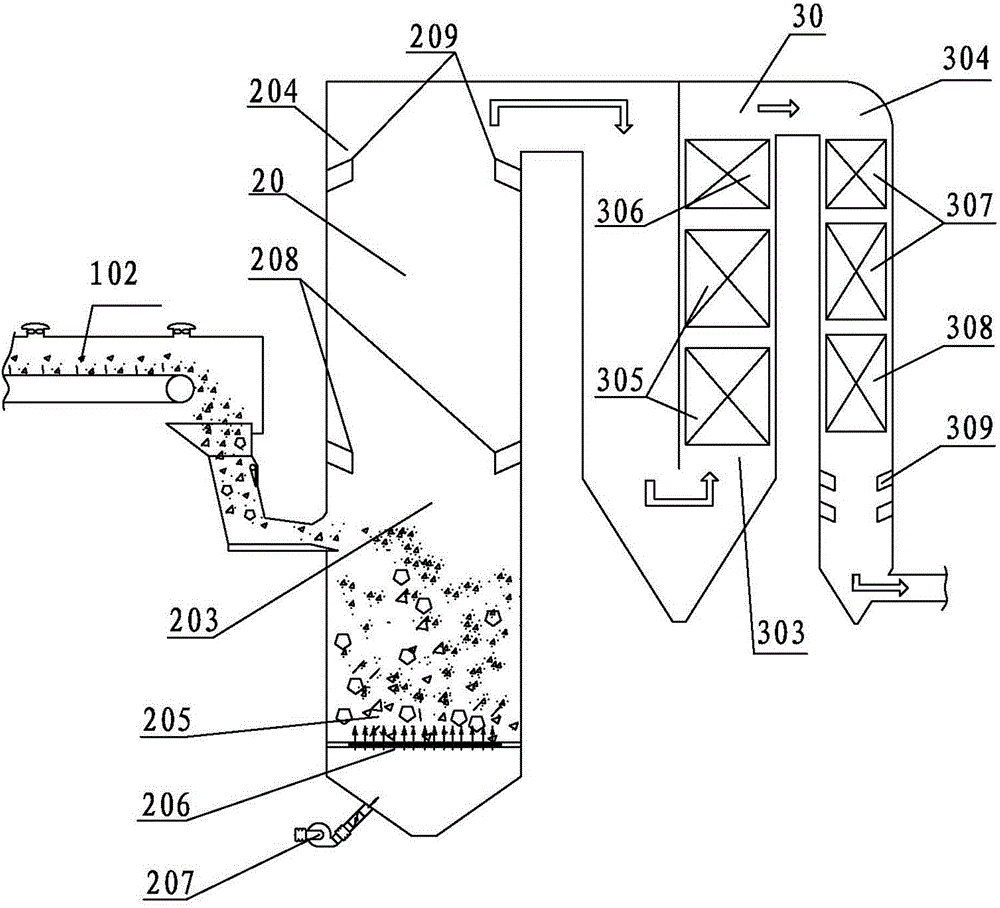

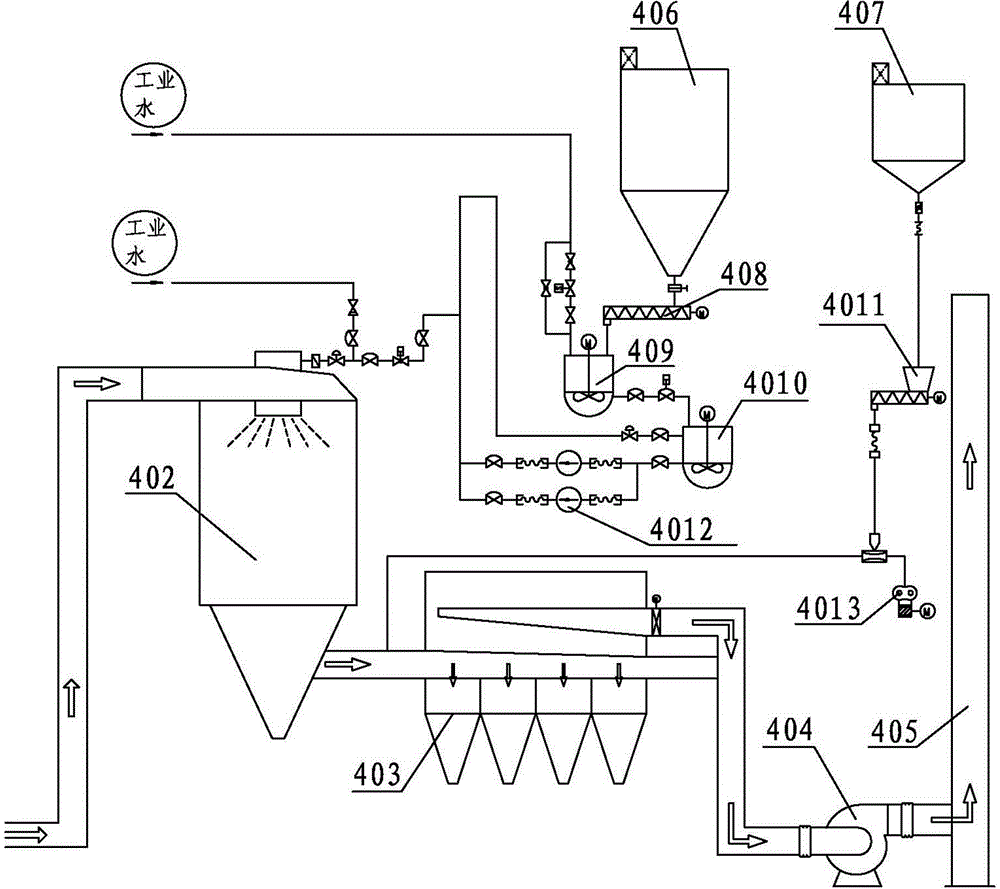

[0030] Such as figure 1As shown, a hazardous waste incineration and waste heat power generation system described in this embodiment includes a continuous feeding device 10, a flue gas purification device 40, a power generation device 50, and an on-line monitoring device 60. The hazardous waste incineration and waste heat power generation system The system also includes a bubbling bed incinerator 20 and a waste heat boiler 30, the continuous feeding device 10 has a disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com