Ammonia absorption type refrigerating apparatus utilizing waste heat of exhaust

An absorption refrigeration and waste heat technology, applied in the field of absorption refrigeration, can solve the problems of low refrigeration coefficient, unused heat, and unrecycled ammonia cooling capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail by the following examples.

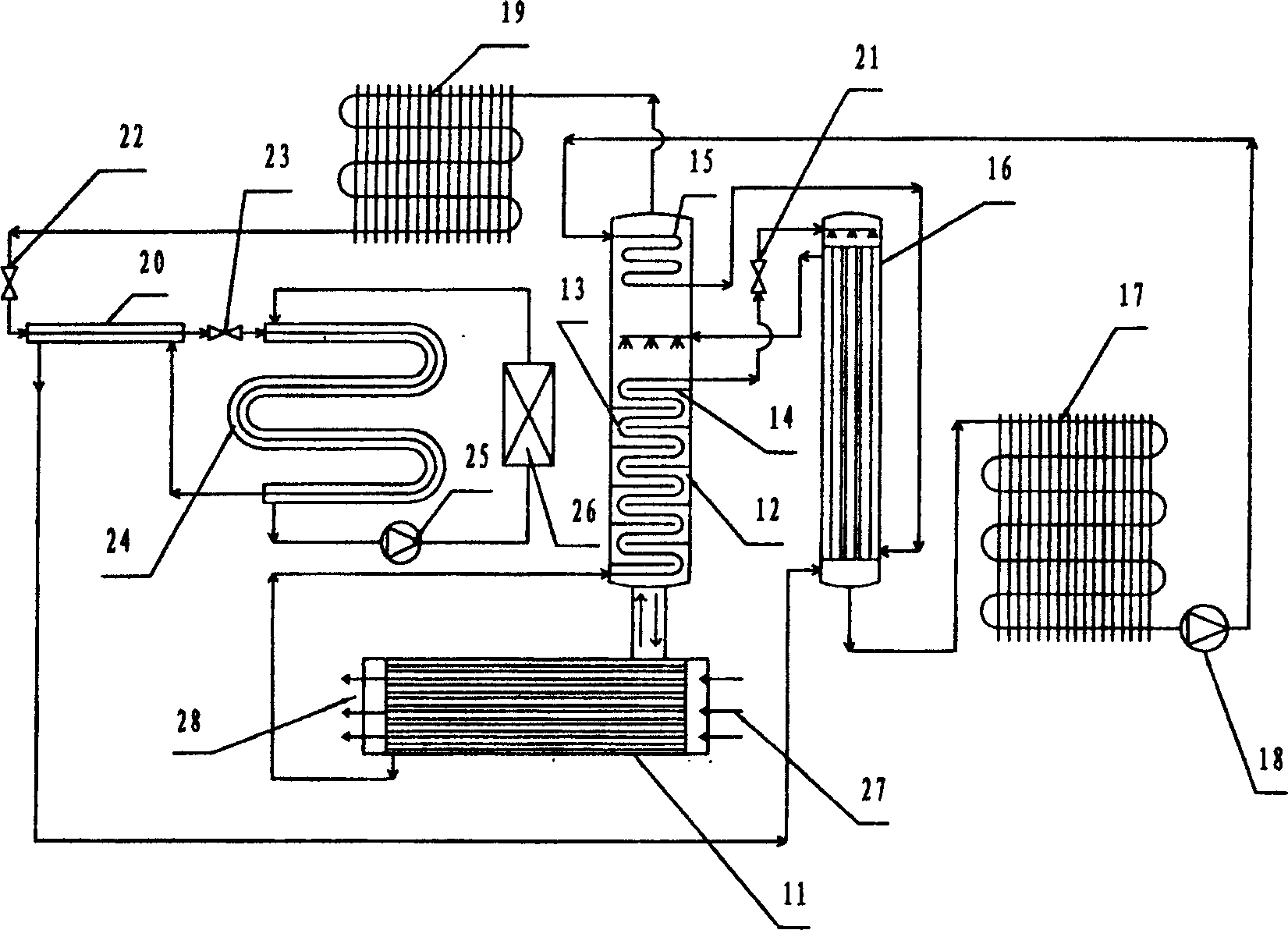

[0019] A kind of ammonia water absorption refrigerating device utilizing tail gas waste heat, such as figure 2 , and its workflow is as follows:

[0020] The high-temperature dilute ammonia solution from the shell-side solution outlet of the waste heat generator 11 enters the regenerator 13, exchanges heat with the lower-temperature concentrated ammonia solution sent back to the waste heat generator 11, and comes out of the regenerator 13 after the temperature drops. It enters the upper part of the generating-absorbing heat exchanger 16 through the solution throttling valve 21 for ammonia absorption and heat exchange, then exits from the bottom of the generating-absorbing heat exchanger 16 and enters the absorber 17 for further ammonia absorption , and dissipate the heat generated by absorption at the same time; the concentrated ammonia solution after coming out from the absorber 17 ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com