Two-section flue gas hot-water single/double-effect composite lithium bromide absorption type refrigerating unit

An absorption refrigeration, flue gas hot water technology, applied in the direction of heating and refrigeration combination, refrigerator, adsorption machine, etc., can solve the problems of reduced economic benefits, lower temperature requirements of high-temperature cooling water return water, and increased number of units, etc. Achieve the effect of improving utilization rate, superior utilization performance and excellent energy saving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

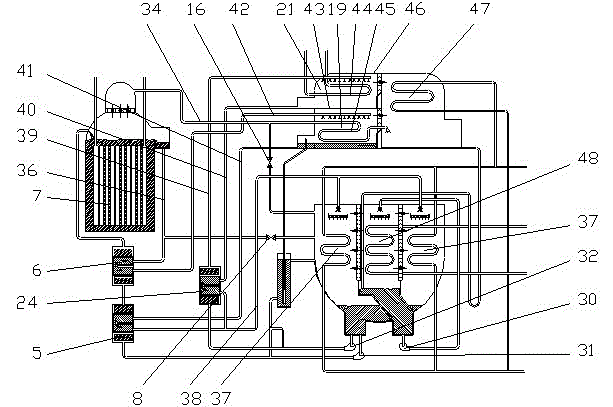

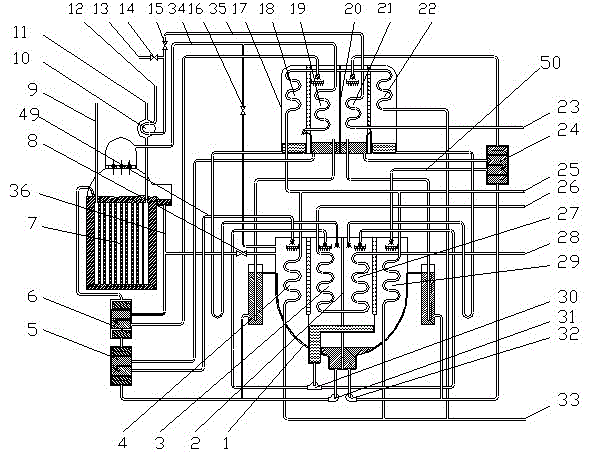

[0019] The present invention as figure 2The unit shown is composed of a flue gas type high-pressure generator 7, a double-effect evaporator 3, a double-effect absorber 4, a double-effect solution pump 31, a high-temperature heat exchanger 6, a low-temperature heat exchanger 5, and a steam generator 19 , double-effect condenser 18, single-effect evaporator 27, single-effect absorber 29, single-effect solution pump 32, single-effect heat exchanger 24, hot water generator 21, single-effect condenser 22, flue gas heat exchanger 10 , the refrigerant pump 30, the control system (not shown in the figure) and the pipelines and valves connecting the components constitute a two-stage flue gas hot water single-double-effect compound lithium bromide absorption chiller and hot water unit. The single-effect condenser 22 and the double-effect condenser 18 are collectively referred to as condensers. The single-effect evaporator 27 and the double-effect evaporator 3 are collectively referred...

Embodiment 2

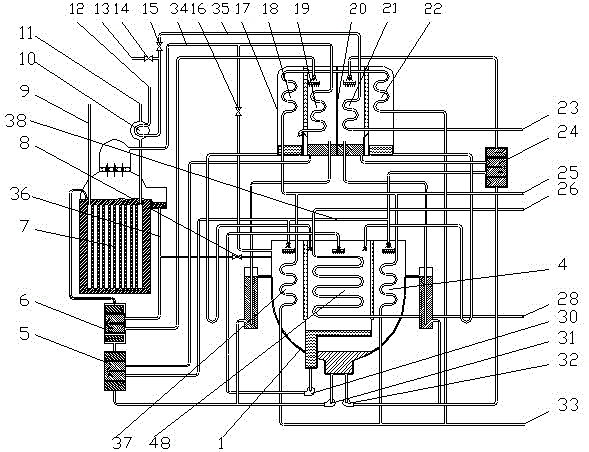

[0023] Cancel figure 2 The shown unit evaporates the evaporative absorber subsection partition 2 in the absorber cylinder 1, and combines the single-effect evaporator 27 and the double-effect evaporator 3 into one evaporator, and combines the single-effect evaporator 29 and the double-effect evaporator 4 Combined into one absorber, the liquid inlet pipe 49 of the double-effect absorber and the liquid inlet pipe 50 of the single-effect absorber are combined into the liquid inlet pipe 38 of the absorber, and the unit becomes a two-stage condenser with a two-stage structure for low emission Flue gas hot water single and double effect composite lithium bromide absorption cold and hot water unit (such as image 3 shown). It is suitable for the unit with this structure when the temperature of the return water of the heat source and hot water only needs to be reduced to about 80°C, which makes the structure of the unit relatively simple.

[0024] When the evaporative absorber adop...

Embodiment 3

[0026] Cancel Figure 2 ~ Figure 4 The solution switching valve, the steam switching valve, the first hot water switching valve and its connecting pipe and the second hot water switching valve in the shown unit, the unit becomes a two-stage flue gas hot water single-effect type for independent refrigeration Composite lithium bromide absorption chiller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com