Sulfur recovery tail gas processing technology and system

A tail gas treatment and sulfur recovery technology, applied in gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems of complex operation and maintenance, easy corrosion of the system, high operating costs, etc., to achieve abundant resources, reduce secondary pollution, maintain and The effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited to this: the present invention is not only applicable to secondary Claus+SCOT sulfur recovery process, tail gas incineration and waste heat recovery process, and semi-dry flue gas desulfurization The combined process is also applicable to SO in the tail gas of other Claus sulfur recovery processes 2 Concentration≤1000mg / Nm 3 Any obvious improvements or changes made by those skilled in the art to the above embodiments will not exceed the concept of the present invention and the protection scope of the claims.

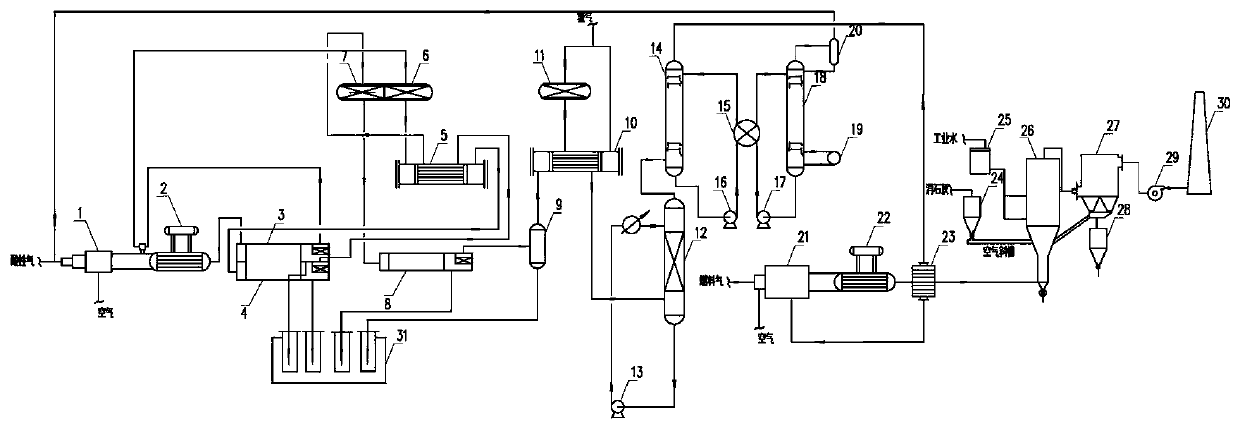

[0022] As shown in the figure: a sulfur recovery tail gas treatment process system:

[0023] 1) Klaus + SCOT process

[0024] Contains H 2 S acid gas enters the acid gas waste heat boiler 2 to by-produce medium-pressure steam through the acid gas combustion furnace 1 under-oxygen combustion, and reduces the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com