Composite ship hybrid power system based on ammonia-hydrogen driving

A hybrid power system and composite technology, applied in the field of ship power plant, can solve the problems of excessive exhaust waste heat utilization rate and low efficiency, and achieve the effect of improving waste heat utilization rate, reducing irreversible loss and protecting marine environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

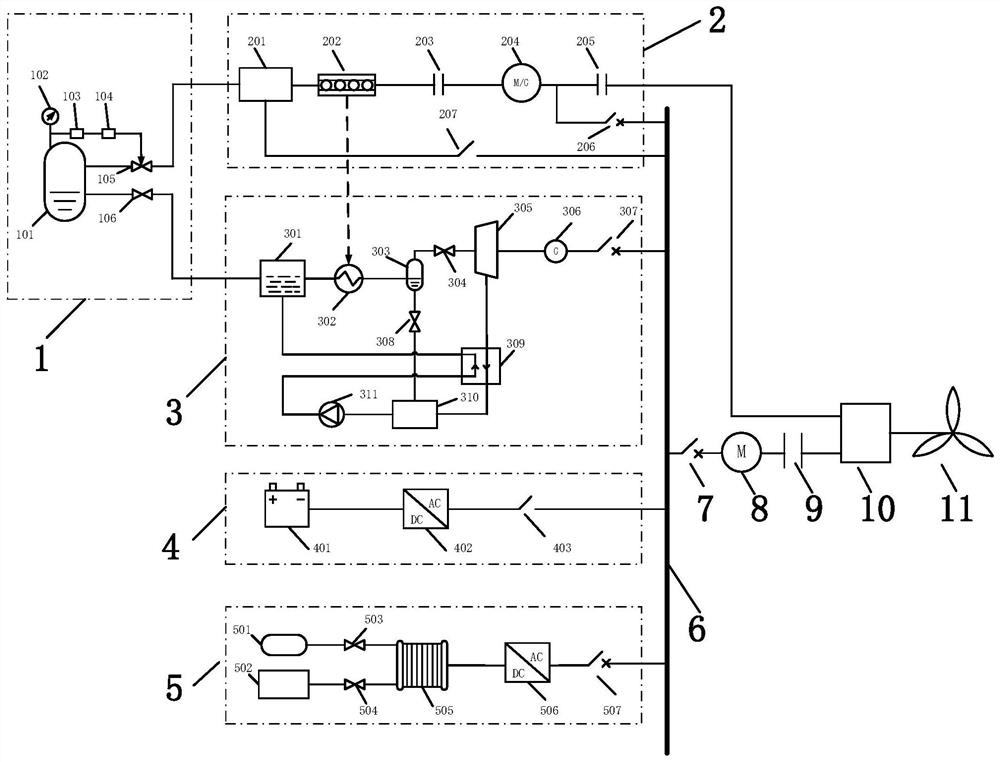

[0020] combine figure 1 , the present invention includes: liquid ammonia supply device 1, ammonia fuel power device 2, waste heat utilization device 3, battery energy storage device 4, hydrogen fuel power device 5, ship main bus 6, main motor switch 7, main motor 8, main clutch 9. Gear box 10, ship propeller 11.

[0021] The liquid ammonia supply device 1 includes a liquid ammonia tank 101 , a pressure gauge 102 , a pressure alarm 103 , a control unit 104 , a first one-way valve 105 , and a second one-way valve 106 . The pressure gauge 102 is installed on the top of the first liquid ammonia tank 101, the pressure gauge 102 is connected to the pressure alarm 103, the pressure alarm 103 is connected to the control unit 104, and the control unit 104 is connected to the electromagnetic valve core of the first one-way valve 105. The first outlet of the ammonia tank i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com