Gas engine driven steam compressing and absorbing combined type heat pump hot water unit running method

A vapor compression, heat pump hot water technology, applied in heat pumps, refrigerators, refrigeration components, etc., can solve problems such as the quality of waste heat is not further improved, the efficiency of energy utilization is not high, and the advantages of gas engine heat pumps cannot be fully utilized. Improve the efficiency and efficiency of primary energy utilization, improve primary energy utilization, and improve the effect of primary energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

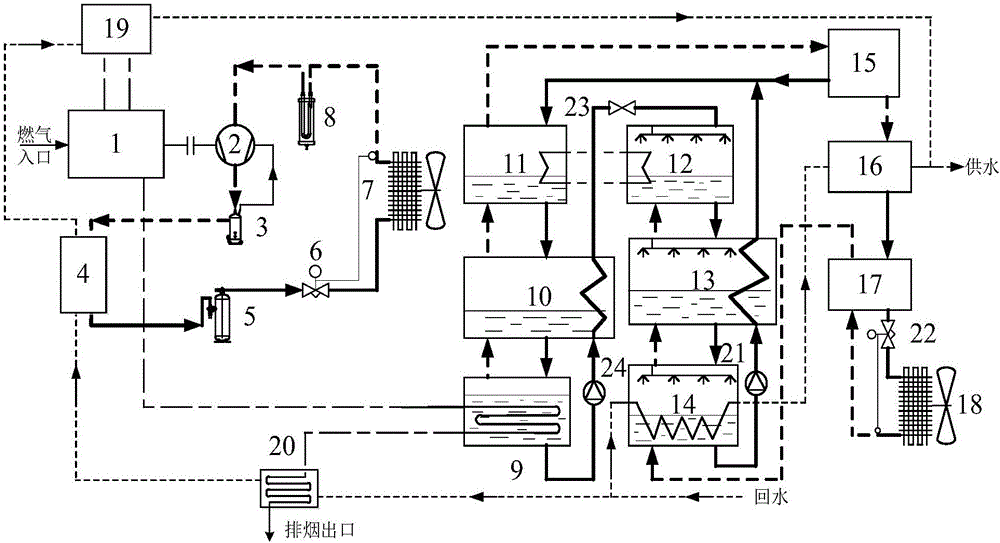

[0029] The gas engine 1 drives the compressor 2 to do work, and compresses the refrigerant in the compression heat pump system into a high-temperature and high-pressure gaseous state. The gaseous refrigerant first passes through the oil separator 3, and then enters the first condenser 4 to be heated by the first user return water. The heat is transferred to the user's return water by exchange, and the refrigerant condenses into a relatively low-temperature high-pressure liquid state, enters the liquid receiver 5, and then expands through the expansion valve 6 to become a low-temperature and low-pressure liquid state and then enters the first evaporator. The first evaporator 7 absorbs the heat of the external environment and evaporates into a gaseous state. The gaseous refrigerant enters the compressor 2 through the gas-liquid separator 8 and is compressed into a high-temperature and high-pressure gaseous state, thus forming a compressed refrigerant cycle. ;

[0030] The waste ...

Embodiment 2

[0035] The gas engine 1 drives the compressor 2 to do work, and compresses the refrigerant in the compression heat pump system into a high-temperature and high-pressure gaseous state. The gaseous refrigerant first passes through the oil separator 3, and then enters the first condenser 4 to be heated by the first user return water. The heat is transferred to the user's return water by exchange, and the refrigerant condenses into a relatively low-temperature high-pressure liquid state, enters the liquid receiver 5, and then expands through the expansion valve 6 to become a low-temperature and low-pressure liquid state and then enters the first evaporator. The first evaporator 7 absorbs the heat of the external environment and evaporates into a gaseous state. The gaseous refrigerant enters the compressor 2 through the gas-liquid separator 8 and is compressed into a high-temperature and high-pressure gaseous state, thus forming a compressed refrigerant cycle. ;

[0036] The waste ...

Embodiment 3

[0041] The gas engine 1 drives the compressor 2 to do work, and compresses the refrigerant in the compression heat pump system into a high-temperature and high-pressure gaseous state. The gaseous refrigerant first passes through the oil separator 3, and then enters the first condenser 4 to be heated by the first user return water. The heat is transferred to the user's return water by exchange, and the refrigerant condenses into a relatively low-temperature high-pressure liquid state, enters the liquid receiver 5, and then expands through the expansion valve 6 to become a low-temperature and low-pressure liquid state and then enters the first evaporator. The first evaporator 7 absorbs the heat of the external environment and evaporates into a gaseous state. The gaseous refrigerant enters the compressor 2 through the gas-liquid separator 8 and is compressed into a high-temperature and high-pressure gaseous state, thus forming a compressed refrigerant cycle. ;

[0042]The waste h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com