Method for controlling precipitation of delta phase in Nb-containing nickel-based superalloy

A technology for nickel-based superalloys and alloys, which is applied in the field of controlling the precipitation of δ phases in nickel-based superalloys containing Nb, and in the field of ultra-supercritical units. It can solve the problems of excessive number of needle-like δ phases and cracks, and achieve the increase of precipitation-strengthening phases. , improve the lasting life and reduce the effect of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Alloy composition (wt.%) of this example: C0.04%, Cr21.5%, Mo9.0%, Nb3.7%, Fe<5.0%, Mn<1.0%, Si<1.0%, Al1.2% , Ti0.6%, B0.005%, Hf0.4%, and the rest is Ni;

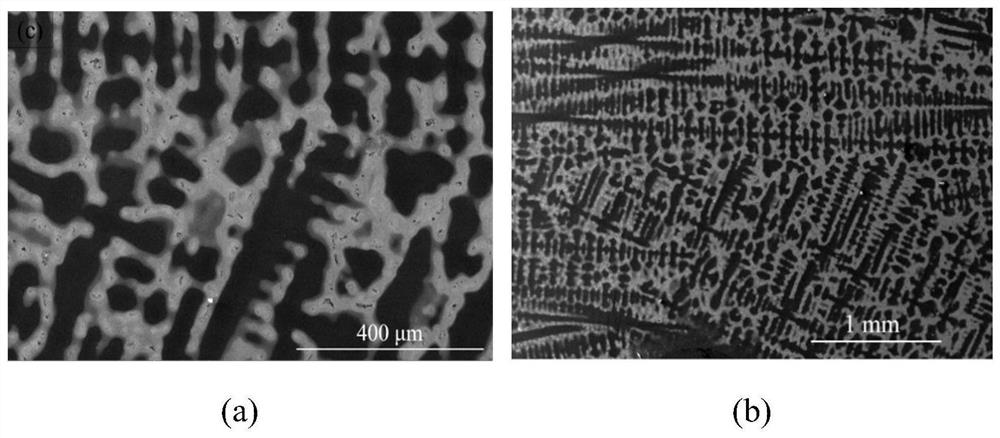

[0042] The metallographic structure of the obtained alloy after heat treatment is as follows: figure 1 Shown, MC carbide and M 23 C 6 The carbides are distributed on the matrix or grain boundaries, and the spherical γ′ strengthening phase is evenly distributed on the matrix.

[0043] The metallographic structure of the alloy after long-term aging at 700℃ for 1000-7000h is shown in figure 2 , it can be seen from the figure that the δ phase precipitated in the alloy structure is controlled to precipitate a small amount near the grain boundary region.

[0044] The properties of the alloy of this embodiment at 700°C are as follows:

[0045] Standard heat treatment: σ b =400MPa, σ 0.2 =205MPa, δ=46.0%, ψ=59.0%. Aging at 650°C for 1000 hours: σ b =530MPa, σ 0.2 =410MPa, δ=36.0%, ψ=43.0%. Aging at 650°C for 30...

Embodiment 2

[0053] Alloy composition (wt.%) of this example: C0.02%, Cr21.5%, Mo9.0%, Nb3.7%, Fe<5.0%, Mn<1.0%, Si<1.0%, Al1.2% , Ti0.6%, B0.005%, Hf0.8%, and the rest is Ni;

[0054] The tensile properties of the alloy at 700°C are as follows

[0055] Standard heat treatment: σ b =360MPa, σ 0.2 = 170MPa, δ = 62.0%, ψ = 64.0%, aging at 650°C for 1000 hours: σ b =600MPa, σ 0.2 =450MPa, δ=37.0%, ψ=31.0%. Aging at 650°C for 3000 hours: σ b =635MPa, σ 0.2 =420MPa, δ=25.0%, ψ=12.0%. Aging at 700°C for 1000 hours: σ b =608MPa, σ 0.2 =495MPa, δ=20.0%, ψ=27.0%. Aging at 700°C for 3000 hours: σ b =705MPa, σ 0.2 =520MPa, δ=26.0%, ψ=28.0%. Aging at 750°C for 1000 hours: σ b =930MPa, σ 0.2 =565MPa, δ=19.0%, ψ=21.0%. Aging at 750°C for 3000 hours: σ b =575MPa, σ 0.2 =500MPa, δ=5.0%, ψ=20.0%.

[0056] Durability performance: aging at 700°C for 1000h, and the durability life at 700°C / 350MPa is >299.95h.

Embodiment 3

[0058] Alloy composition of this example: C0.03%, Cr21.5%, Mo9.0%, Nb3.7%, Fe<5.0%, Mn<1.0%, Si<1.0%, Al0.9%, Ti0.6% , B0.005%, Hf0.5%, and the rest are Ni;

[0059] The tensile properties of the alloy at 700°C are as follows

[0060] Standard heat treatment: σ b =400MPa, σ 0.2 =195MPa, δ=59.0%, ψ=57.0% 650°C aging for 1000 hours: σ b =480MPa, σ 0.2 =375MPa, δ=40.0%, ψ=64.0%. Aging at 650°C for 3000 hours: σ b =585MPa, σ 0.2 =480MPa, δ=22.0%, ψ=35.0%. Aging at 700°C for 1000 hours: σ b =640MPa, σ 0.2 =456MPa, δ=32.0%, ψ=38.0%. Aging at 700°C for 3000 hours: σ b =665MPa, σ 0.2 =485MPa, δ=25.0%, ψ=31.0%. Aging at 750°C for 1000 hours: σ b =693MPa, σ 0.2 =445MPa, δ=22.0%, ψ=26.0%. Aging at 750°C for 3000 hours: σ b =775MPa, σ 0.2 =485MPa, δ=18.0%, ψ=32.0%.

[0061] Durability performance: aging at 700°C for 1000h, and the durability life at 700°C / 350MPa is >299.95h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com