Selective laser melting forming method of hot-crack-free precipitation strengthened high-temperature alloy

A technology of selective laser melting and precipitation strengthening, applied in the direction of additive processing, etc., can solve the problems of small 3D printing process window, inability to guarantee process stability, weakening of material strength, etc., achieve high versatility, flexible and convenient production, and improve mechanics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a selective laser melting forming method for athermal crack precipitation strengthening superalloy, the method includes the following steps:

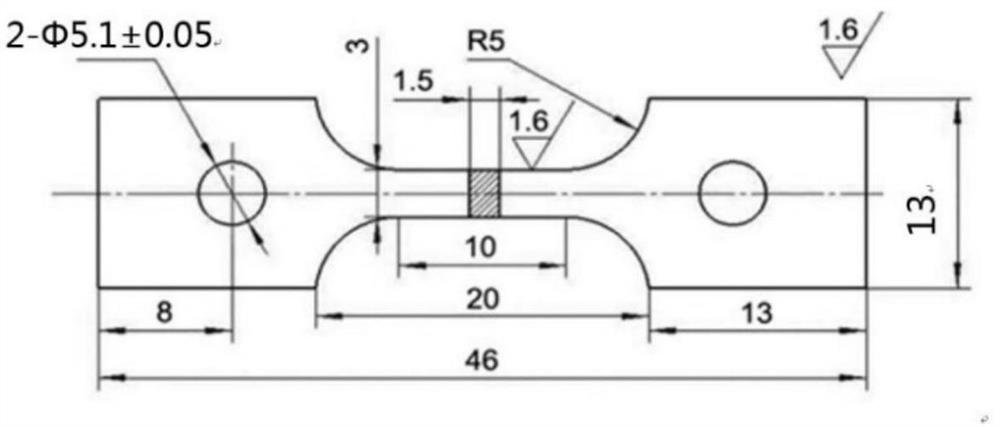

[0044] Among them, the present embodiment prepares a kind of such as figure 1 The tensile test piece shown is made of IN738LC precipitation-strengthened superalloy.

[0045] (1) Mix IN738LC precipitation-strengthened high-temperature alloy powder with a particle size D90 of 40 μm and demelting element particles (hafnium elemental powder) with a particle size of 1 to 5 μm at a mass ratio of 99:1 to obtain a mixed powder;

[0046] (2) Vacuumize the cavity of the selective laser melting equipment to 10 -3 Pa, filled with high-purity argon, repeated 3 times, the mixed powder described in step (1) was added into the molding cavity to form a powder layer with a thickness of 30 μm, the powder layer was preheated to 200 ° C, and the The mixed powder is melted and formed. The power of the laser is 230w, the beam...

Embodiment 2

[0049] This embodiment provides a selective laser melting forming method for athermal crack precipitation strengthening superalloy, the method includes the following steps:

[0050] Among them, the present embodiment prepares a kind of such as figure 1 The tensile test piece shown is made of IN738LC precipitation-strengthened superalloy.

[0051] (1) Mix IN738LC precipitation-strengthened high-temperature alloy powder with a particle size D90 of 40 μm and demelting element particles (hafnium elemental powder) with a particle size of 1 to 5 μm at a mass ratio of 99:1 to obtain a mixed powder;

[0052] (2) Vacuumize the cavity of the selective laser melting equipment to 10 -3 Pa, filled with high-purity argon, repeated 3 times, the mixed powder described in step (1) was added into the molding cavity to form a powder layer with a thickness of 30 μm, the powder layer was preheated to 200 ° C, and the The mixed powder is melted and formed. The power of the laser is 230w, the beam...

Embodiment 3

[0055] This embodiment provides a selective laser melting forming method for athermal crack precipitation strengthening superalloy, the method includes the following steps:

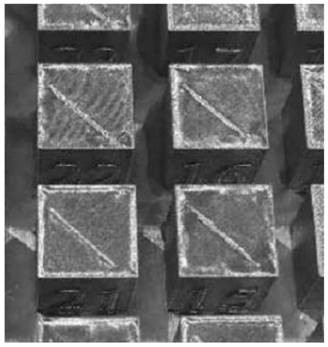

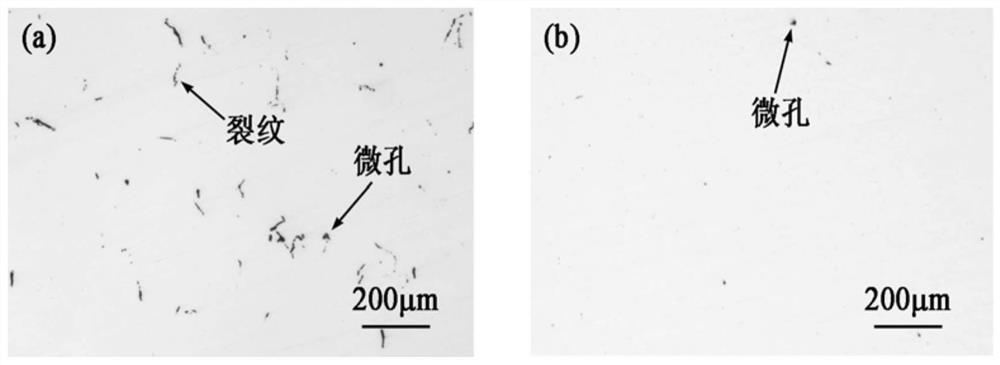

[0056] Among them, the present embodiment prepares a kind of such as Figure 4 The cubic shape shown (10×10×10mm 3 ) specimen, the material is IN738LC precipitation strengthened superalloy.

[0057] (1) Mix IN738LC precipitation-strengthened high-temperature alloy powder with a particle size D90 of 40 μm and demelting element particles (hafnium elemental powder) with a particle size of 1-5 μm at a mass ratio of 98:2 to obtain a mixed powder;

[0058] (2) Vacuumize the cavity of the selective laser melting equipment to 10 -3 Pa, filled with high-purity argon, repeated 3 times, the mixed powder described in step (1) was added into the molding cavity to form a powder layer with a thickness of 30 μm, the powder layer was preheated to 200 ° C, and the The mixed powder is melted and formed. The power of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com