Metal-ceramic composite coating layer for steel piston

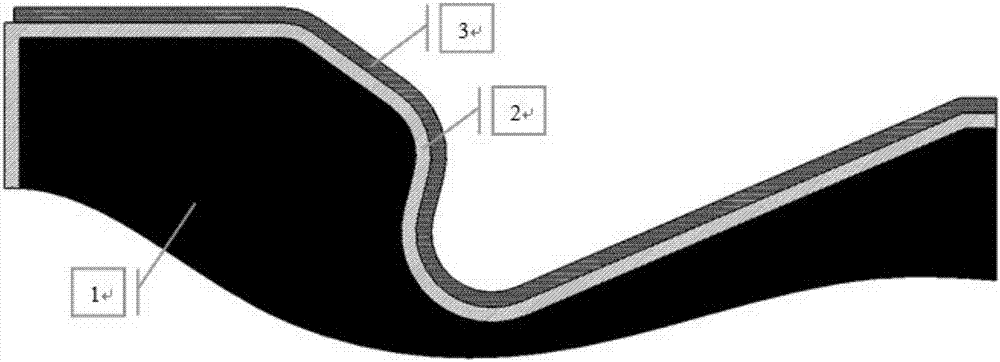

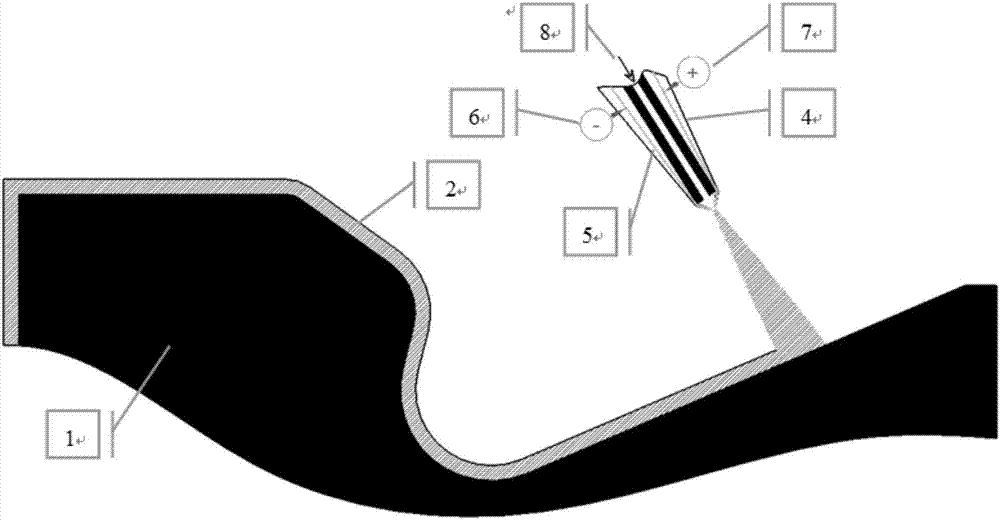

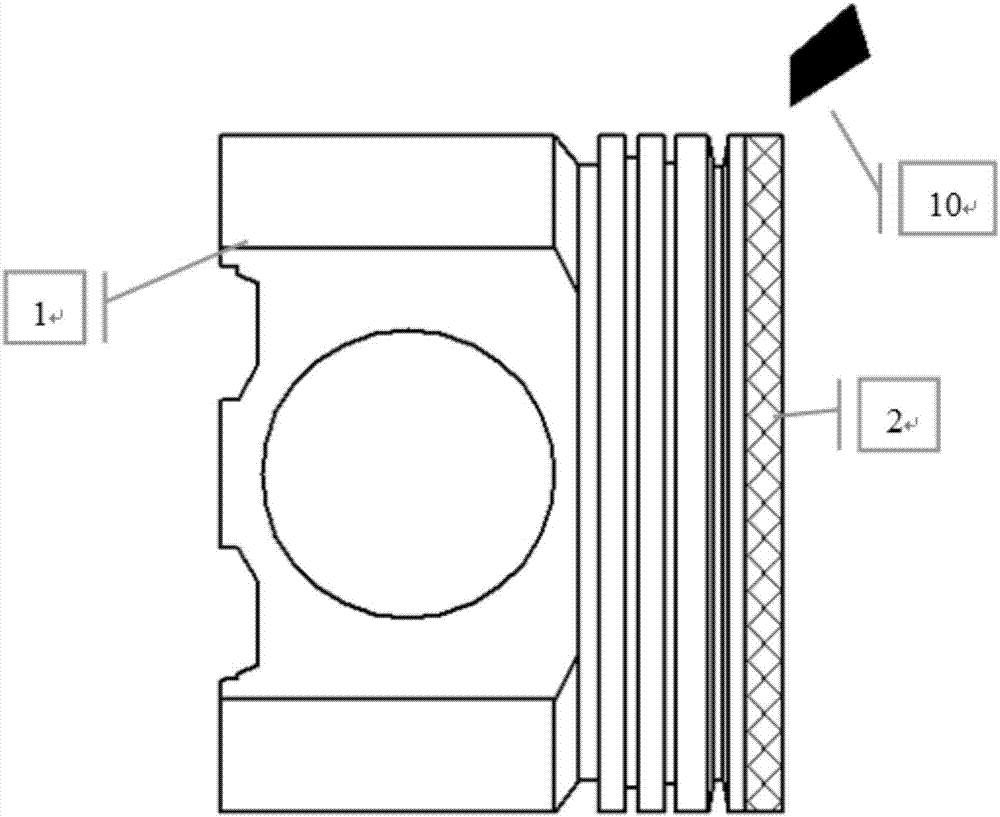

A ceramic composite, steel piston technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the problems of high temperature strength drop, large coating thickness, corrosion and other problems, to reduce heat conduction downward, Simple preparation method and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The steps of the method are:

[0052] Reserved size→2, arc sprayed pure aluminum metal layer→3, secondary machining→4, hard anodizing.

[0053] Detailed description: (Assuming that the metal layer is a and the ceramic layer is b, the total thickness of the coating is A=a+b / 2)

[0054] 1. Reserve size: Before preparing the coating, you need to reserve a size for the thickness of the coating to prevent the thickness of the coating from affecting the size of the piston. The specific method is to process an extra layer in the area to be processed when processing the piston. Consistent with coating thickness A;

[0055] 2. Arc spraying pure aluminum metal layer: the pure aluminum layer is sprayed on the predetermined position by the arc spraying process, the spraying voltage is 30-50V, the current is 200-300A, the pure aluminum wire with a purity of 99.999% is used, the wire diameter is 1.0mm, and the wire feeding speed is 10 -20mm / s, compressed air pressure 0.6-0.8MPa, time 3-5min...

Embodiment 2

[0059] The steps of the method are:

[0060] Reserved size→2, arc spraying pure magnesium metal layer→3, secondary machining→4, hard anodizing.

[0061] Detailed description: (Assuming that the metal layer is a and the ceramic layer is b, the total thickness of the coating is A=a+b / 2)

[0062] 1. Reserve size: Before preparing the coating, you need to reserve a size for the thickness of the coating to prevent the thickness of the coating from affecting the size of the piston. The specific method is to process an extra layer in the area to be processed when processing the piston. Consistent with coating thickness A;

[0063] 2. Arc spraying pure magnesium metal layer: the pure magnesium layer is sprayed on the predetermined position by the arc spraying process, the spraying voltage is 30-50V, the current is 200-300A, the pure magnesium wire with a purity of 99.999% is used, the wire diameter is 1.0mm, and the wire feeding speed is 10 -20mm / s, compressed air pressure 0.6-0.8MPa, time 3...

Embodiment 3

[0067] The steps of the method are:

[0068] Reserved size→2, arc sprayed pure titanium metal layer→3, secondary machining→4, hard anodizing.

[0069] Detailed description: (Assuming that the metal layer is a and the ceramic layer is b, the total thickness of the coating is A=a+b / 2)

[0070] 1. Reserve size: Before preparing the coating, you need to reserve a size for the thickness of the coating to prevent the thickness of the coating from affecting the size of the piston. The specific method is to process an extra layer in the area to be processed when processing the piston. Consistent with coating thickness A;

[0071] 2. Arc sprayed pure titanium metal layer: the pure titanium layer is sprayed on the predetermined position by the arc spraying process, the spraying voltage is 30-50V, the current is 200-300A, the pure titanium wire with a purity of 99.999% is used, the wire diameter is 1.0mm, and the wire feeding speed is 10 -20mm / s, compressed air pressure 0.6-0.8MPa, time 3-5min....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com