Method for avoiding hot crack on outer layer of high speed steel roll for rods and wires

A high-speed steel, rod and wire technology, applied in the field of centrifugal casting of rolls, can solve problems such as thermal cracks, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

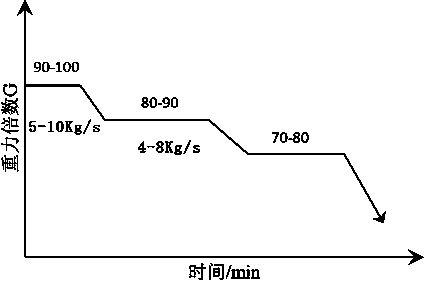

[0028] There is a high-speed steel centrifugal roll for rolling rods and wires. Its size is Φ430×650×1535 mm, the thickness of the working layer is 55mm, and the total amount of molten steel in the outer layer is about 320Kg. The outer layer pouring steps of the high-speed steel roll are as follows:

[0029] (1) Before pouring, the centrifuge idles for 10 minutes with the casting mold, and starts pouring after the centrifugal pouring system runs smoothly, and the speed is controlled at 740r / min (centrifugal gravity multiple is about G=100);

[0030] (2) The temperature measured before the pouring of the outer layer of molten steel is 1500°C;

[0031] (3) When pouring starts, quickly pour 130Kg of molten steel within 16s, then reduce the speed of the centrifuge to 700 r / min, at this time reduce the pouring flow, and pour the remaining 190Kg of molten steel into the rotary in 40s In the mold.

[0032] (4) After all the outer layer of molten steel is poured, sprinkle anti-oxidat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com