A method for controlling the brittle laves phase in the process of laser additive manufacturing of nickel-based superalloy

A nickel-based superalloy, laser additive technology, applied in additive manufacturing, additive processing, energy efficiency improvement and other directions, can solve the problem of not completely removing long chain Laves, reduce cracking sensitivity, improve cooling rate, The effect of suppressing the segregation of Nb element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] S1. Preliminarily optimize the process parameters of laser additive manufacturing, obtain the preliminary laser additive manufacturing process window, and optimize the parameters: the average laser power is 400W, the scanning speed is 6mm / s, the powder feeding amount is 8g / min, and the spot diameter is 1 ~2mm, carrier gas flow rate 10L / min;

[0024] S2. Use tap water to cool the bottom of the nickel-based substrate to reduce heat accumulation during the forming process;

[0025] S3. Carry out laser additive manufacturing of nickel-based superalloys. The laser light source is controlled by a square wave. The parameters of the square wave are: peak power: 600W, pulse frequency: 10HZ-100HZ, duty cycle: 0.6.

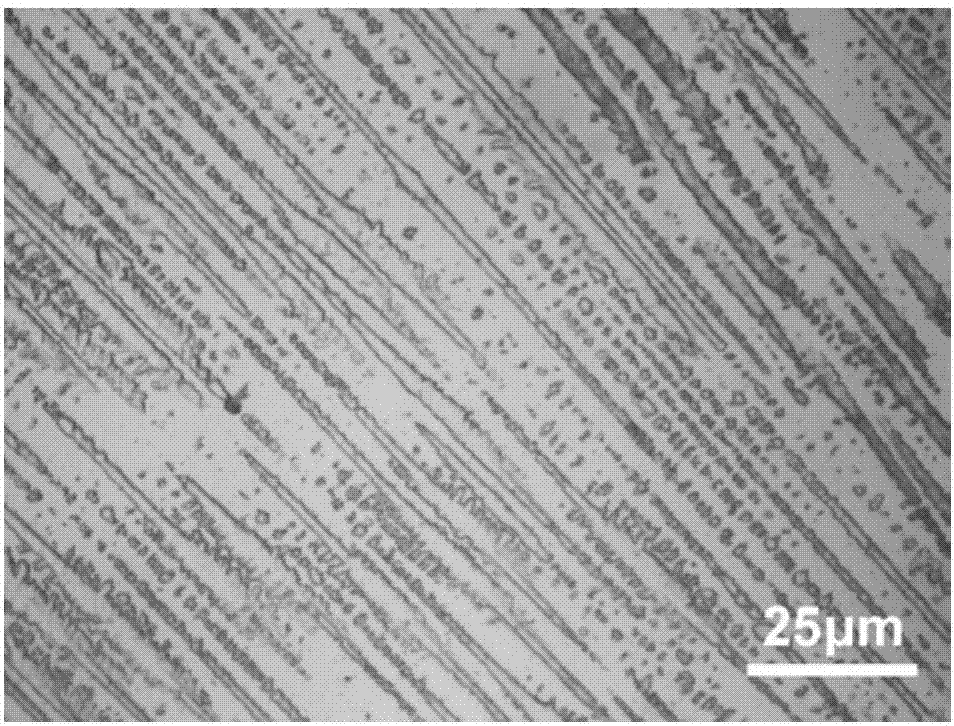

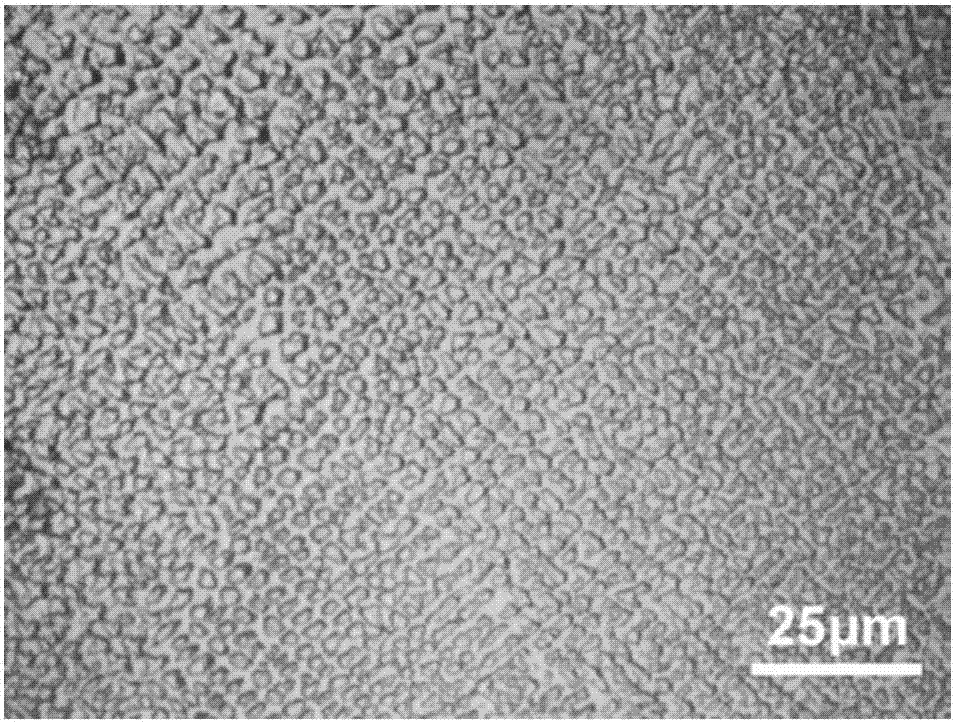

[0026] figure 2 It is the metallographic structure map obtained by adopting the laser modulation method of the present invention; from figure 2 It can be seen that the metallographic structure is composed of fine equiaxed dendrites; figure 1 The metallographic st...

Embodiment 2

[0032] S1. Preliminarily optimize the process parameters of laser additive manufacturing, obtain the preliminary laser additive manufacturing process window, and optimize the parameters: the average laser power is 400W, the scanning speed is 10mm / s, the powder feeding amount is 12g / min, and the spot diameter is 1 ~2mm, carrier gas flow rate 12L / min;

[0033] S2. Use tap water to cool the bottom of the nickel-based substrate to reduce heat accumulation during the forming process;

[0034] S3. Carry out laser additive manufacturing of nickel-based superalloys. The laser light source is controlled by a sawtooth wave. The parameters of the sawtooth wave are: peak 900W, valley 0W, pulse frequency: 90HZ.

Embodiment 3

[0036]S1. Preliminarily optimize the process parameters of laser additive manufacturing, obtain the preliminary laser additive manufacturing process window, and optimize the parameters: the average laser power is 600W, the scanning speed is 8mm / s, the powder feeding amount is 10g / min, and the spot diameter is 1mm , carrier gas flow rate 10L / min;

[0037] S2. Use liquid nitrogen to cool the bottom of the nickel-based substrate to reduce heat accumulation during the forming process;

[0038] S3. Carry out laser additive manufacturing of nickel-based superalloys. The laser light source is controlled by a sine wave. The parameters of the sine wave are: peak 700W, valley 0W, pulse frequency: 30HZ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com