Anode plate of stainless-steel cold-rolling pickling line and manufacture method thereof

A manufacturing method and pickling line technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problem of high cost, and achieve the effect of moderate manufacturing cost, enhanced corrosion resistance, and fine and uniform grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation of the anode plate of the stainless steel cold-rolled pickling line and its manufacturing method will be described in detail below in conjunction with the examples and accompanying drawings, but the specific implementation of the anode plate of the stainless steel cold-rolling pickling line and its manufacturing method are not limited in the following examples.

[0034] Example of anode plate

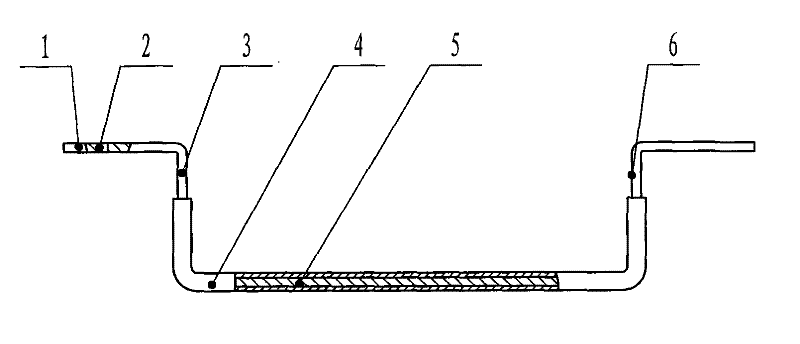

[0035] figure 1 The anode plate of the described stainless steel cold rolling pickling line has a core plate 6 . The longitudinal section of the core plate 6 is in the shape of a handle. The core plate 6 includes two side plates 3 and a bottom plate 5. There is an outwardly bent mounting plate 1 on each of the upper sides of the mounting plate 1, and there is an electrical connection through hole 2 on the mounting plate 1. The core plate 6 is 4500mm long, 580mm high, and the cross-sectional specification is 200mm×24mm. The main part of the core plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com