Gear steel 20CrMoSH and technology for improving hardenability stability thereof

A gear steel, hardenability technology, applied in the field of gear steel and its production process, can solve the problems of narrow hardenability control, hardenability fluctuation, composition segregation, etc., to achieve long service life, stable hardenability, production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0026] Embodiment 1-8: Gear steel 20CrMoSH and the production process for improving its hardenability stability are as follows:

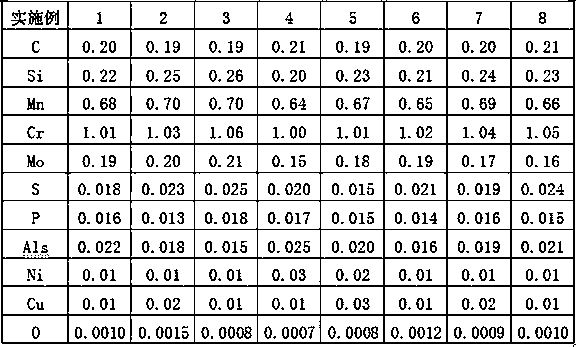

[0027] (1) Composition ratio: The specific composition ratio of 20CrMoSH steel in each embodiment is shown in Table 1:

[0028] Table 1: Chemical composition (wt%) of each embodiment

[0029]

[0030] In Table 1, the balance of the components is Fe and unavoidable impurities.

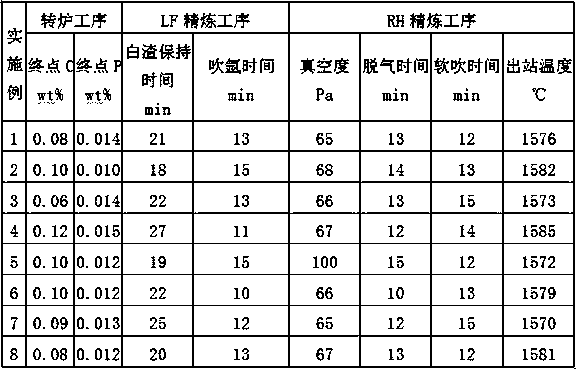

[0031](2) Process conditions: See Table 2 for the specific process parameters of the converter, LF refining, and RH refining processes in each embodiment, see Table 3 for the specific process parameters of the continuous casting process, and see Table 4 for the specific process parameters of the heating and rolling process: Table 2: Specific process parameters of converter, LF refining and RH refining processes

[0032]

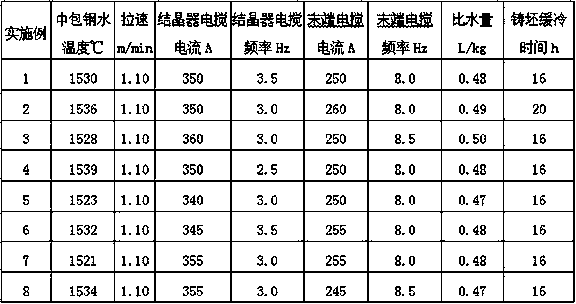

[0033] Table 3: Specific process parameters of continuous casting process

[0034]

[0035] Table 4: Specific process parameters of heating and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com