High-precision cold drawn pipe and manufacturing method thereof

A manufacturing method and technology of cold-drawn pipes, which are applied in the field of steel pipes, can solve problems such as unmentioned strength, achieve the effects of reducing heat treatment deformation, ensuring precision, and improving impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

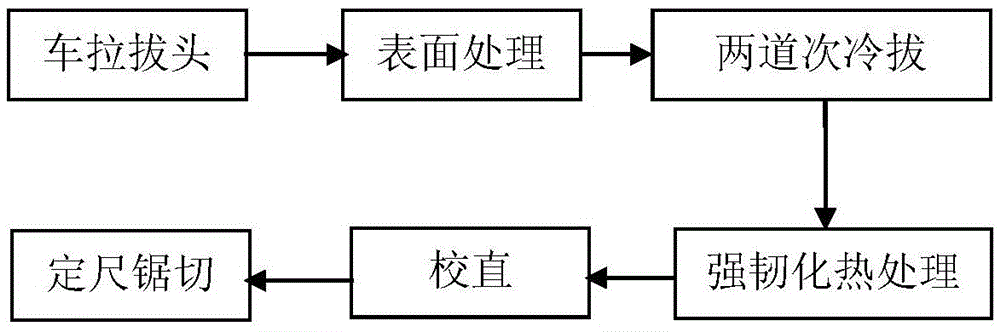

[0027] The present invention will be further described below in conjunction with accompanying drawing.

[0028] A high-precision cold-drawn tube, using low-alloy high-strength structural steel as a blank, the chemical element composition and mass percentage content are: carbon C≤0.20%, silicon Si≤0.50%, manganese Mn≤1.70%, phosphorus P≤0.035% , sulfur S≤0.035%, niobium Nb≤0.07%, vanadium V≤0.20%, titanium Ti≤0.20%, chromium Cr≤0.30%, nickel Ni≤0.80%, copper Cu≤0.30%, nitrogen N≤0.015%, molybdenum Mo≤0.20%, aluminum Al element and trace boron B element are added to adjust steelmaking quality and mechanical properties, and the balance is iron Fe.

[0029] Preferably, when vanadium V≤0.15%, nickel Ni≤0.50%, nitrogen N≤0.012%, molybdenum Mo≤0.10%, tensile strength≥700Mpa, impact energy≥27.

[0030] Preferably, when vanadium V≤0.20%, nickel Ni≤0.50%, nitrogen N≤0.015%, molybdenum Mo≤0.10%, tensile strength≥745Mpa, impact energy≥27.

[0031] Preferably, when vanadium V≤0.20%, nick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com