Quenching machining tool for heat treatment and cooling for track plate

A heat treatment cooling and quenching machine tool technology, which is applied in heat treatment furnaces, heat treatment equipment, quenching devices, etc., can solve problems such as uneven hardness, slow heat dissipation, and soft spots, and achieve good quality stability, small heat treatment deformation, and high hardness. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

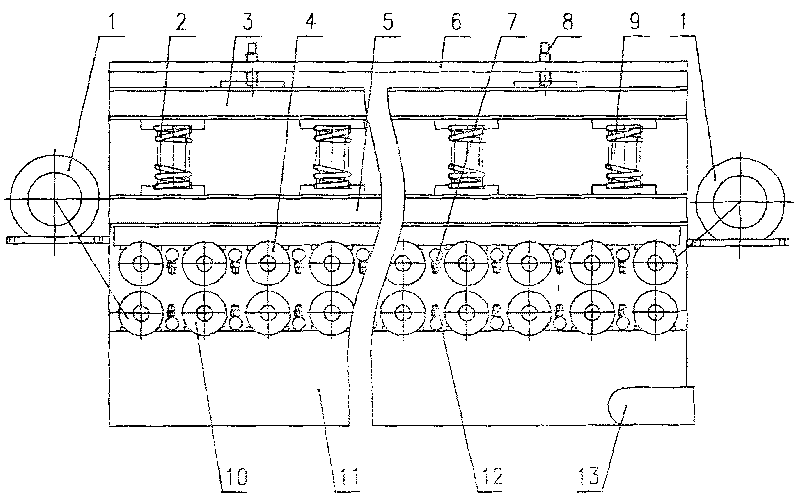

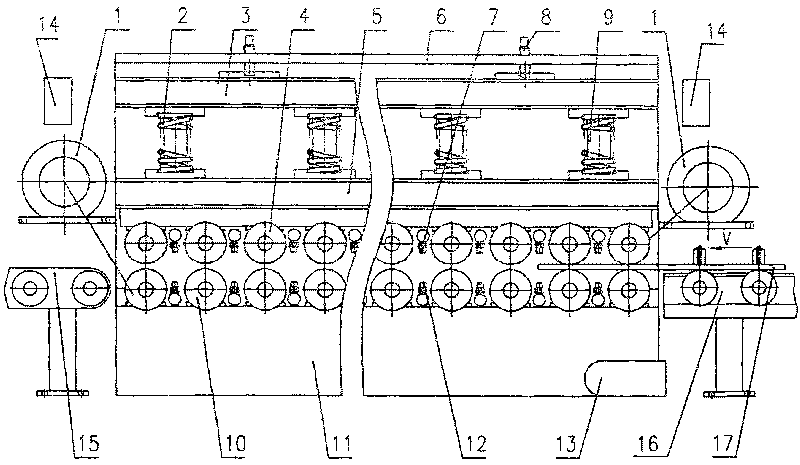

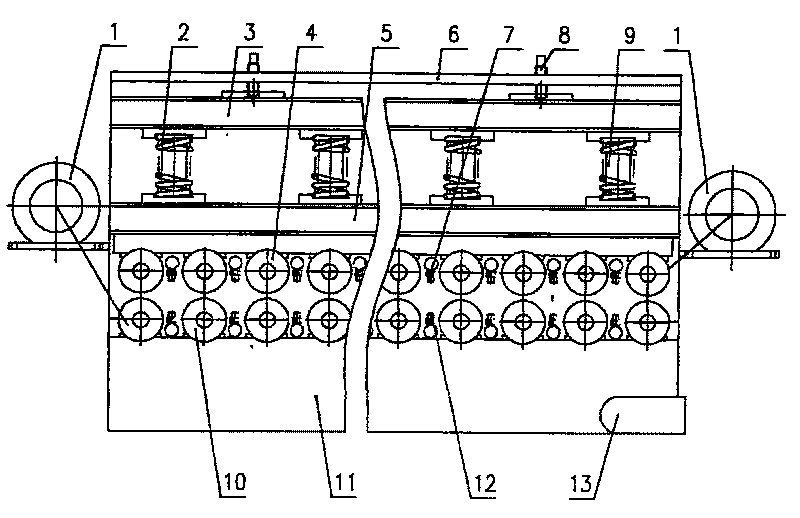

[0008] refer to figure 1 , it includes a box body 11, the lower part of the box body has a drain pipe 13 connected to the reservoir through the pipeline, and several lower drive rollers 10 are installed on the upper part of the box body, and several lower drive rollers are connected with each other by chains, and are all on a horizontal plane , arranged in a straight line, lower water spray nozzles 12 are installed between each lower driving roller, an upper driving roller frame 5 is arranged above the lower driving roller, and the upper driving roller frame is connected with the upper beam 3 above it through the connecting rod 9 Sliding connection, the connecting rod is equipped with a compression spring 2, the upper beam is connected with the bed 6 through the screw 8, the bed is fixedly connected with the box body, and several upper transmission rollers 4 are installed under the upper transmission roller frame, and several upper transmission rollers are uploaded The moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com