Manufacturing process of external gear drum type broach fine gear cutter disc

A manufacturing process and cutter head technology, which is applied in the manufacturing process field of fine-cutting gear cutter heads for external gear barrel broaches, can solve the problems of reducing the processing quality of parking gears, low manufacturing precision of cutter heads, and long manufacturing cycle of cutter heads, etc. Achieve the effects of reducing processing costs, facilitating operation, and reducing plane unevenness errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

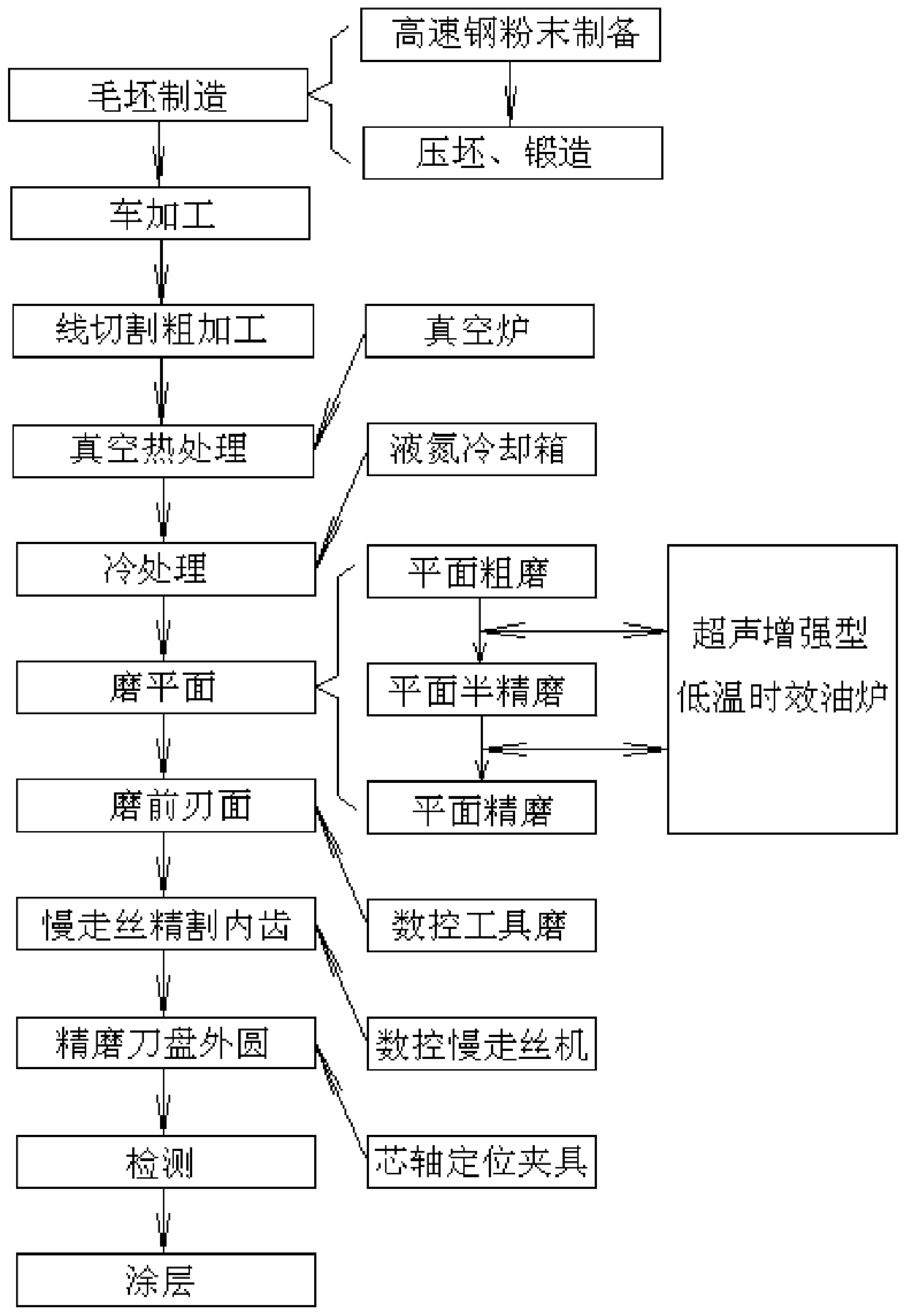

[0060] Such as Figures 1 to 7 Shown is an embodiment of the manufacturing process of a fine-cut toothed cutterhead for an external tooth cylinder type broach of the present invention, including the following process steps:

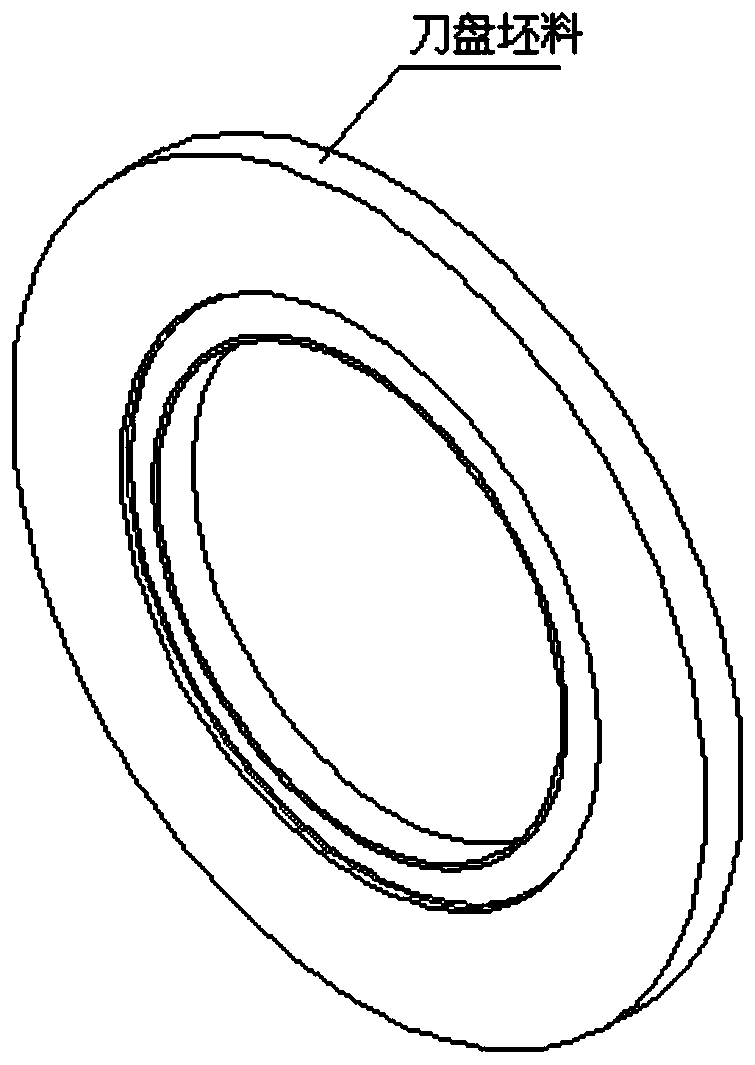

[0061] (1) Blank manufacturing: the high-speed steel powder is pressed and forged at high temperature and high pressure to make a cutter head blank;

[0062] (2) Turning processing: use a CNC lathe to install the cutter head blank on a precision chuck for turning processing; among them, the inner hole, end face, and front edge face of the cutter head are processed in one clamping to ensure the size of each part. Concentricity and perpendicularity;

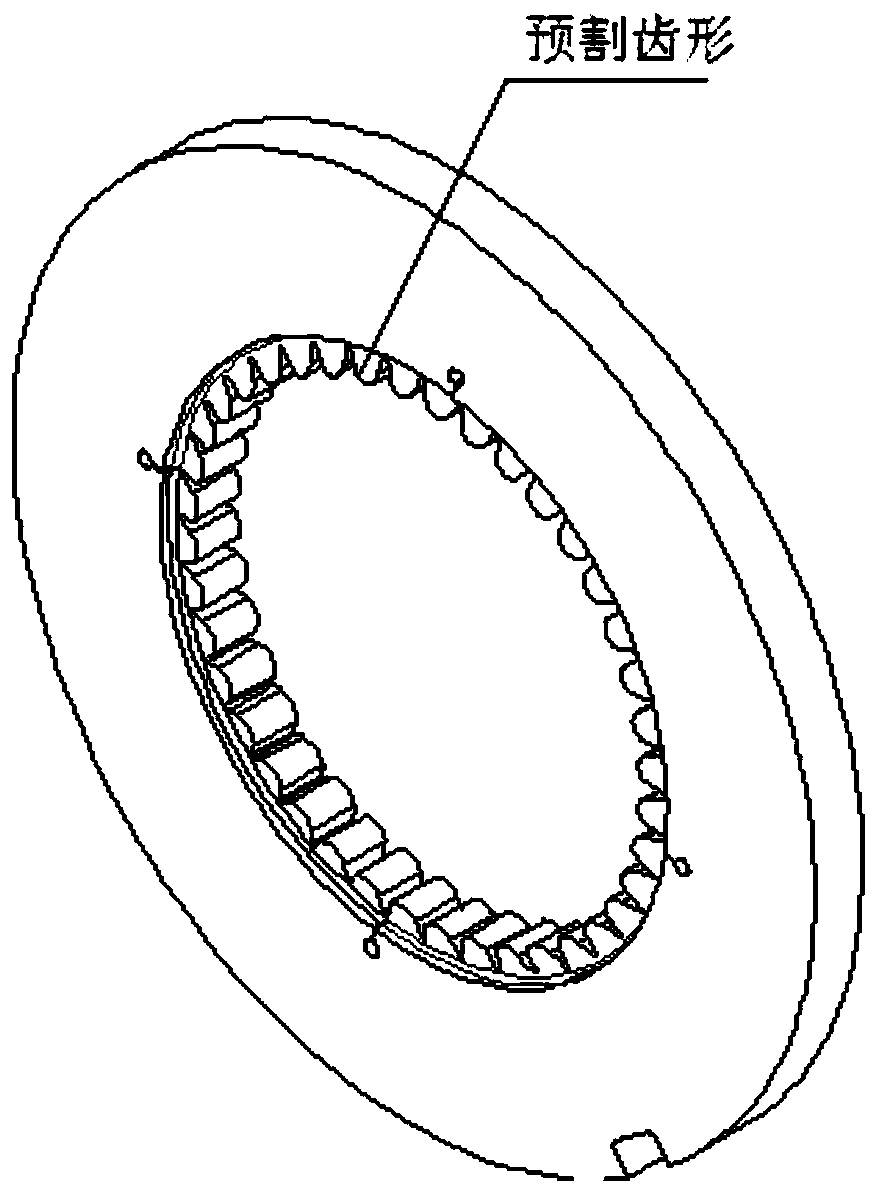

[0063] (3) Wire-cut rough machining: Use CNC wire-cut electric discharge machine tools to rough-machine the internal teeth and positioning keyways of the cutterhead;

[0064] (4) Vacuum heat treatment: place the wire-cut rough-processed cutter head in a vacuum furnace for vacuum quenching and vacuum temperin...

Embodiment 2

[0095] The Klingelnberg Gear Testing Center is used to detect the fine-cutting cutter head of the external gear barrel broach in Example 1, and input the fine-cutting cutter head according to the German standard DIN3962, the national standard GB / T 10095 and the Japanese standard JIS B1751, etc. Parameters and technical indicators are tested to comprehensively evaluate the manufacturing accuracy level of the fine-cutting cutter head. The detection structure is as follows:

[0096] Testing Standard Execution precision class Test results German standard DIN3962 Level 7 qualified National standard GB / T 10095 Level 7 qualified Japanese standard JIS B1751 Level 3 qualified

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com