Preparation method of high-toughness gel electrolyte and all-solid-state zinc-air battery with firm interface

A gel electrolyte and high toughness technology, applied in the field of energy storage devices, can solve the problems of reducing the performance of flexible batteries, achieve the effect of reducing battery polarization and interface contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

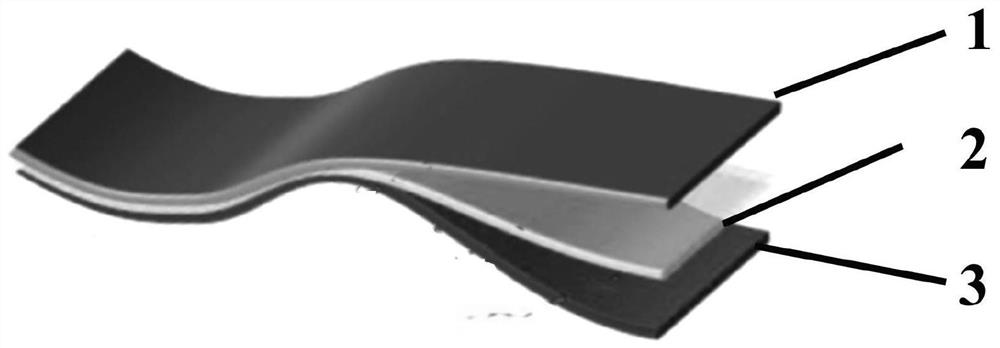

[0031] 1. Preparation of carbon cloth air electrode

[0032] The air electrode is composed of nine cobalt octasulfide powder loaded on carbon cloth. Wash and dry the carbon cloth with alcohol and deionized water. The electrode slurry is prepared from nine cobalt octasulfide powder, conductive carbon black, deionized water, isopropanol and Nafion solution. The catalyst slurry prepared by ultrasonication for 30min was uniformly coated on the cleaned carbon cloth, and the loading capacity was about 1 mg cm -2 . Subsequently, the prepared air electrode was dried overnight at room temperature. The prepared carbon cloth air electrode can be obtained.

[0033] 2. Electrolyte preparation

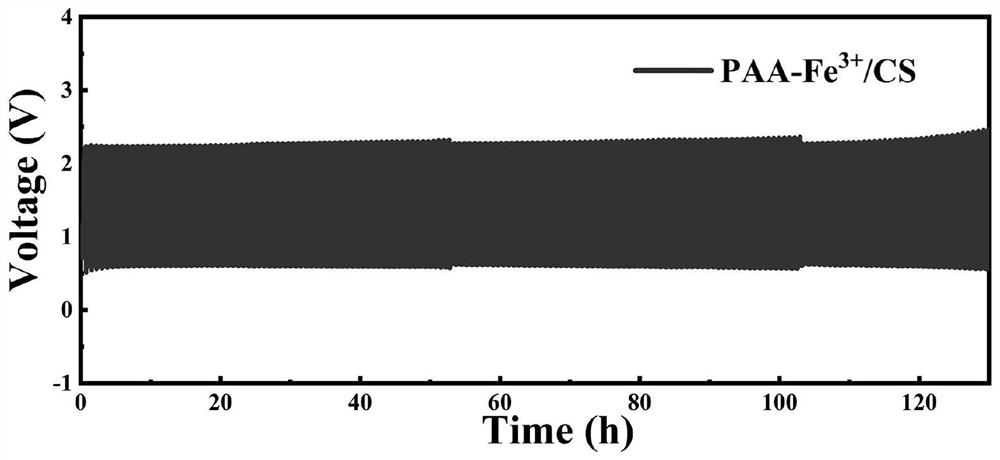

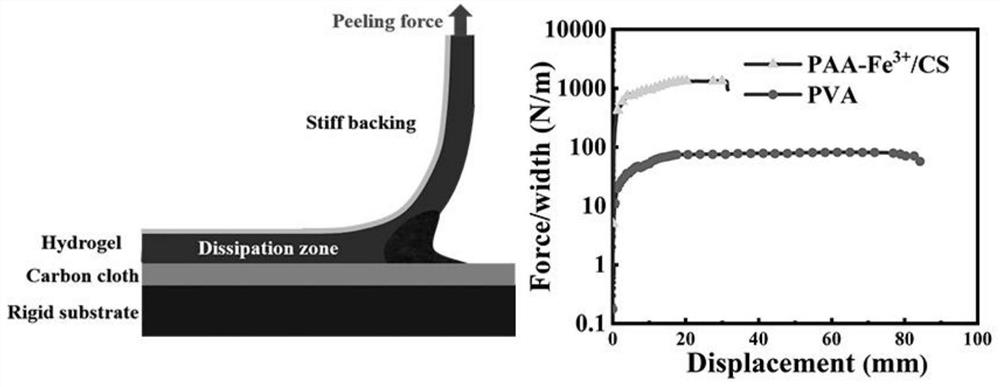

[0034] PAA-Fe 3+ / CS hydrogel: first weigh 1-2g chitosan and dissolve it in the aqueous solution, and stir it magnetically at room temperature. Acrylic acid (AA, 10-20g), crosslinker N,N'-methylenebisacrylamide (MBA, 90ul, 20mg / mL) and ferric chloride hexahydrate (FeCl 3 6H2O, 1 g) was stirre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com