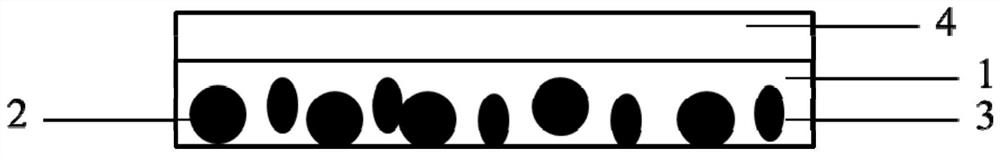

All-solid-state battery electrode and preparation method and application thereof

An all-solid-state battery and solid-state electrolyte technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, electrode manufacturing, etc., can solve problems such as poor contact and large battery internal resistance, achieve simple production process, reduce preparation processes, and enrich ions. The effect of the transmission channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

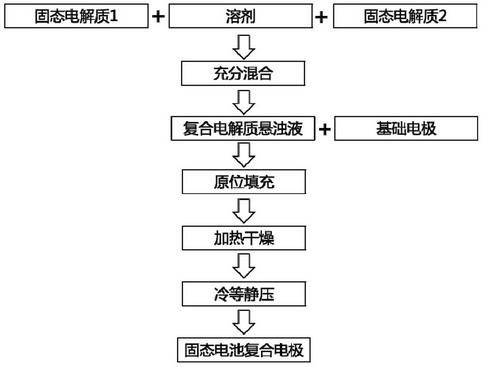

[0067] This embodiment provides a method for preparing an all-solid-state battery electrode, the method comprising the following steps:

[0068] (1) Provide a basic positive electrode, the basic positive electrode uses aluminum foil as the positive electrode current collector, and uses a surface-coated LiNbO 3 Nickel cobalt lithium manganese oxide is used as positive electrode active material, adopts carbon nanofiber as positive electrode conductive agent, adopts polytetrafluoroethylene as positive electrode binder, and the mass ratio of described positive electrode active material, positive electrode conductive agent, positive electrode binder is 97: 1:2, the compacted density of the basic positive electrode is 3g / cm 3 ;

[0069] (2) will Li 6 P.S. 5 Add ethanol to dissolve Br, then add Li 10 GeP 2 S 12 Mix well, control Li 6 P.S. 5 Br and Li 10 GeP 2 S 12 The molar ratio is 1:1, resulting in Li 6 P.S. 5 Br and Li 10 GeP 2 S 12 ethanol suspension;

[0070] (3) ...

Embodiment 2

[0073] This embodiment provides a method for preparing an all-solid-state battery electrode, the method comprising the following steps:

[0074] (1) Provide a basic positive electrode, the basic positive electrode uses aluminum foil as the positive electrode current collector, and uses a surface-coated Li 2 O-ZrO 2 Lithium nickel cobalt aluminate is used as positive electrode active material, adopts carbon nanofiber as positive electrode conductive agent, adopts polytetrafluoroethylene as positive electrode binder, and the mass ratio of described positive electrode active material, positive electrode conductive agent, positive electrode binder is 96: 1:3, the compacted density of the basic positive electrode is 3g / cm 3 ;

[0075] (2) will Li 6 P.S. 5 Cl was dissolved in methanol, then Li 2 S-SiS 2 Mix well, control Li 6 P.S. 5 Cl and Li 2 S-SiS 2 The molar ratio is 1:20, resulting in Li 6 P.S. 5 Cl and Li 2 S-SiS 2 Methanol suspension;

[0076] (3) Cast the susp...

Embodiment 3

[0079] This embodiment provides a method for preparing an all-solid-state battery electrode, the method comprising the following steps:

[0080] (1) Provide a basic negative electrode, the basic negative electrode adopts copper foil as the negative electrode current collector, adopts graphite as the negative electrode active material, adopts acetylene black as the negative electrode conductive agent, adopts polyimide as the negative electrode binder, and the negative electrode active material , the mass ratio of the negative electrode conductive agent and the negative electrode binder is 99:0.5:0.5, and the compacted density of the basic negative electrode is 3g / cm 3 ;

[0081] (2) will Li 6 P.S. 5 Add n-butanol to dissolve, then add Li 7 La 3 Zr 2 o 12 Mix well, control Li 6 P.S. 5 with Li 7 La 3 Zr 2 o 12 The molar ratio is 1:10, resulting in Li 6 P.S. 5 and Li 7 La 3 Zr 2 o 12 n-butanol suspension;

[0082] (3) Infiltrate the suspension obtained in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com