Method for preparing a high-performance slab solid oxide fuel single battery

A solid oxide and single-cell technology, which is applied in the direction of solid electrolyte fuel cells and fuel cell components, can solve the problems of unguaranteed interface contact reliability, large interface contact resistance, and large differences between different batteries, so as to prevent The effect of the failure of the electrolyte diaphragm, the reduction of the interface contact resistance, and the half of the preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

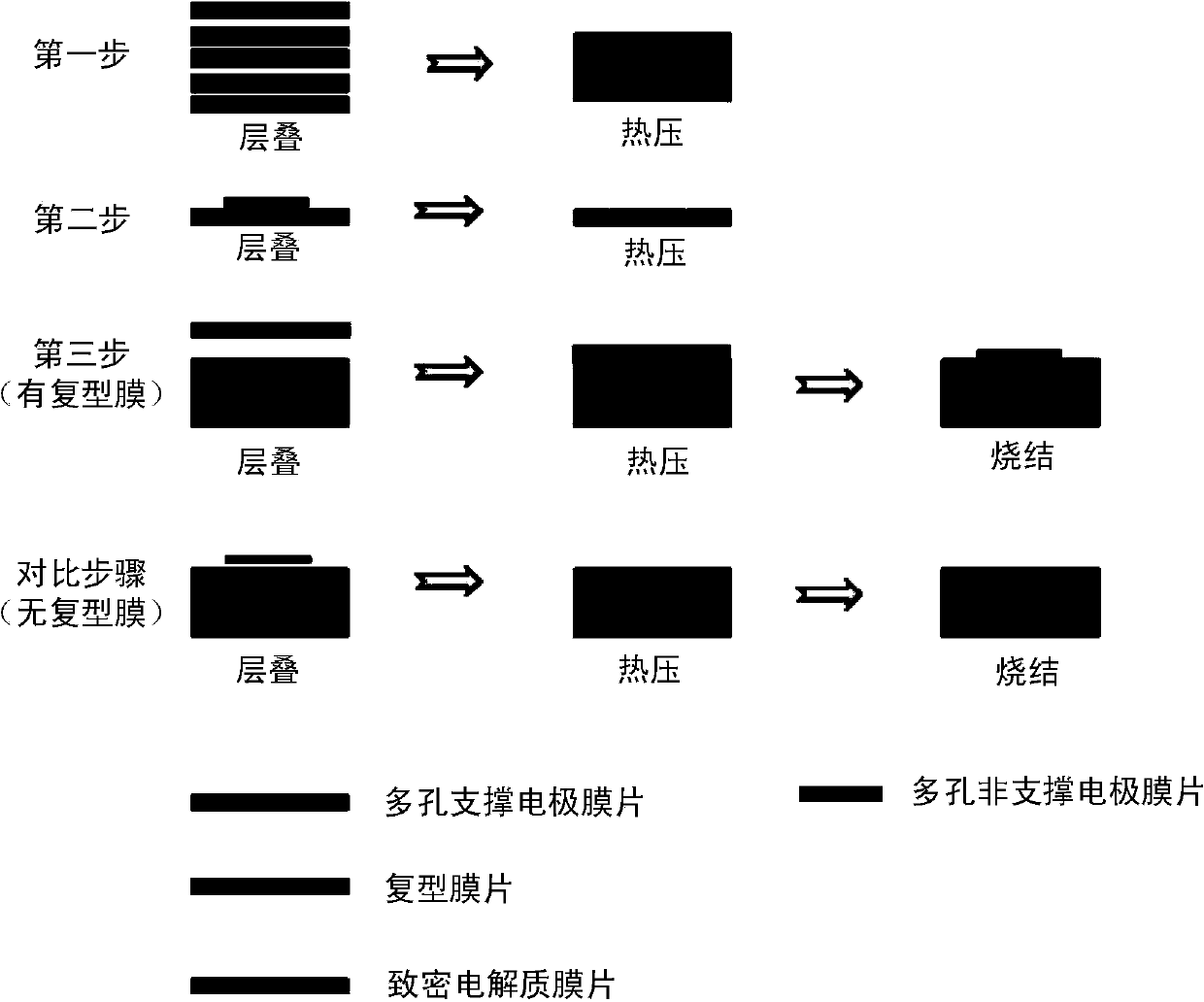

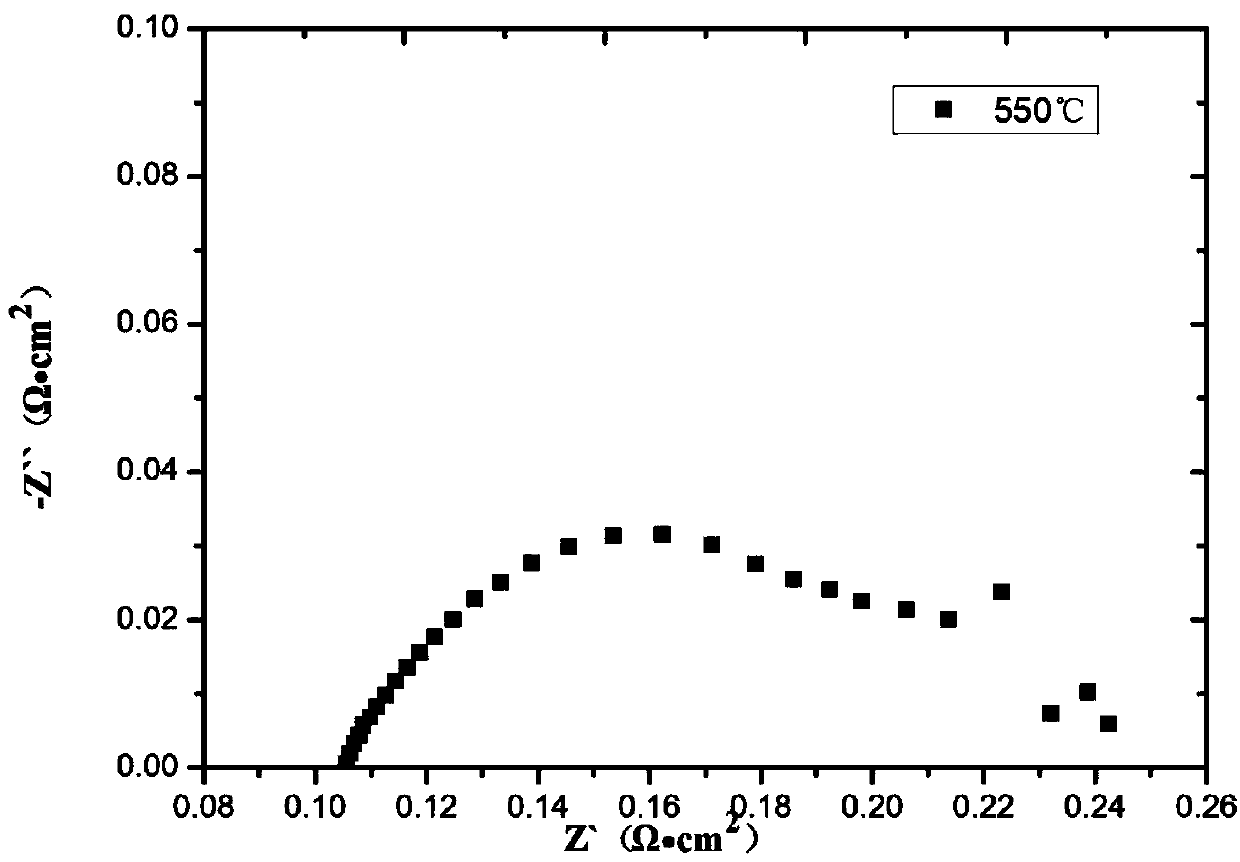

[0059] Battery Structure I: "Porous Electrolyte / Dense Electrolyte / Porous Electrolyte" Structure

[0060] Weigh an appropriate amount of commercial powder LSGM (lanthanum strontium gallium magnesium), use alcohol and methyl ethyl ketone as a solvent, add an appropriate amount of additives to prepare a slurry suitable for casting, and cast an LSGM electrolyte body; weigh an appropriate amount of commercial Powder LSGM (lanthanum strontium gallium magnesium), pore-forming agent, use alcohol and methyl ethyl ketone as solvents, add appropriate amount of additives, prepare slurry suitable for casting, and cast LSGM porous electrode body; weigh an appropriate amount of high temperature flammable Using alcohol and methyl ethyl ketone as solvents, adding appropriate amount of additives to prepare a slurry suitable for casting, and casting to obtain a composite film blank. A "porous electrolyte / dense electrolyte" support body was obtained by superimposing three layers of porous electro...

Embodiment 2

[0063] Cell Structure II: "Cathode Support / Dense Electrolyte / Anode" Structure

[0064] Weigh an appropriate amount of commercial powder LSM (strontium-doped lanthanum manganate) and NiO, use alcohol and methyl ethyl ketone as a solvent, add an appropriate amount of additives to prepare a slurry suitable for casting, and cast the LSM / NiO cathode support. Electrode body: Weigh an appropriate amount of commercial powder 8YSZ (8% yttrium fully stabilized zirconia), use alcohol and methyl ethyl ketone as solvents, add appropriate amount of additives to prepare a slurry suitable for casting, and cast to obtain 8YSZ electrolyte Green body: Weigh an appropriate amount of commercial powder 8YSZ (8% yttrium fully stabilized zirconia) and NiO, use alcohol and methyl ethyl ketone as solvents, add appropriate amount of additives to prepare a slurry suitable for casting, and cast to obtain an anode Green body: Weigh an appropriate amount of high-temperature combustible powder carbon powder,...

Embodiment 3

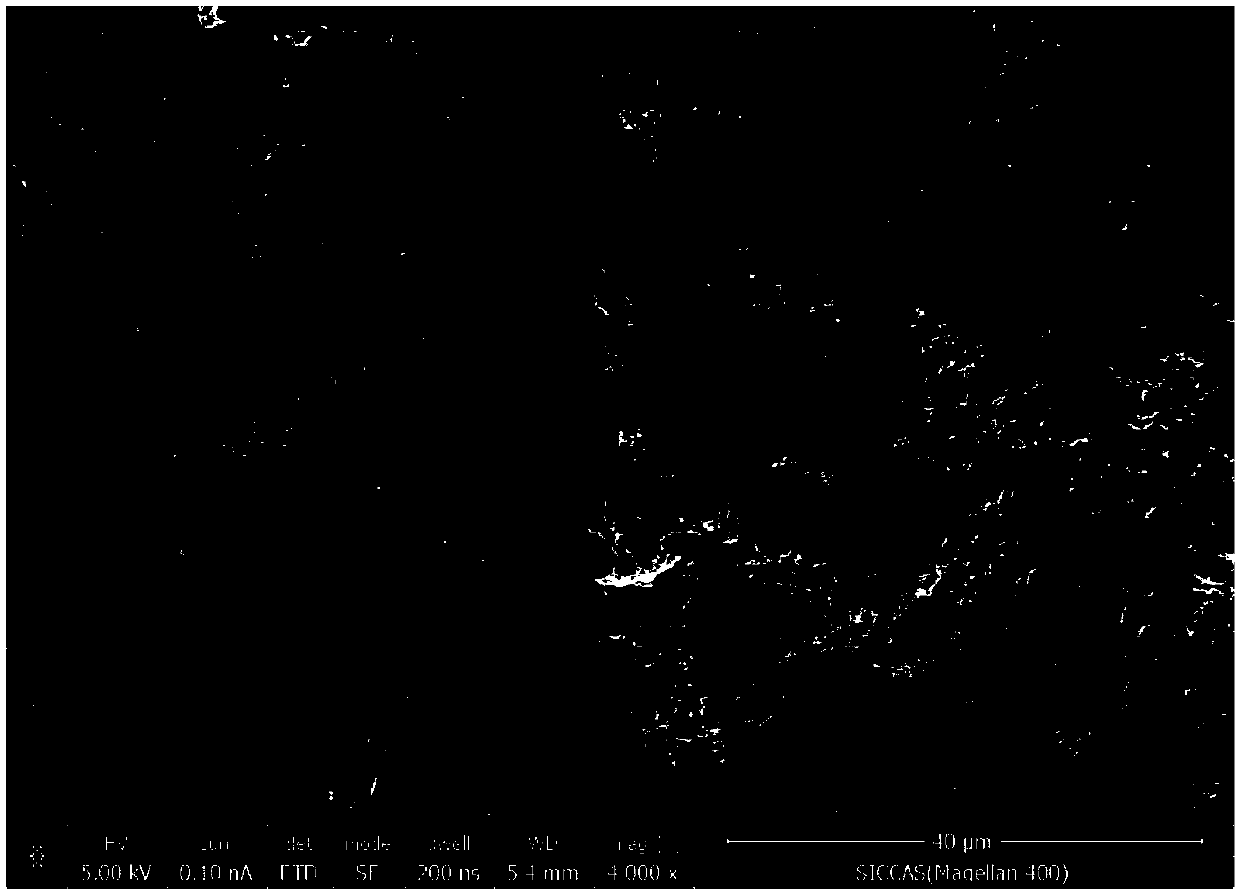

[0066] Cell Structure III: "Anode Support / Dense Electrolyte / Porous Electrolyte" Structure

[0067] Weigh an appropriate amount of commercial powder 8YSZ (8% yttrium fully stabilized zirconia) and NiO, use alcohol and methyl ethyl ketone as a solvent, add an appropriate amount of additives to prepare a slurry suitable for casting, and cast to obtain YSZ / NiO support Body electrode body; Weigh an appropriate amount of commercial powder 8YSZ (8% yttrium fully stabilized zirconia), use alcohol and methyl ethyl ketone as solvents, add appropriate amount of additives to prepare a slurry suitable for casting, and cast to obtain 8YSZ Electrolyte green body; weigh an appropriate amount of commercial powder SSZ (10% scandium fully stabilized zirconia), pore-forming agent, use alcohol and methyl ethyl ketone as solvents, add appropriate amount of additives, and prepare a slurry suitable for casting. The porous electrolyte body is obtained by stretching; an appropriate amount of high-tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com