All-solid-state lithium air battery and manufacturing method therefor

A lithium-air battery, all-solid-state technology, applied in hybrid batteries, fuel cell half-cells, primary battery-type half-cells, circuits, etc., can solve the problem of increased internal resistance of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

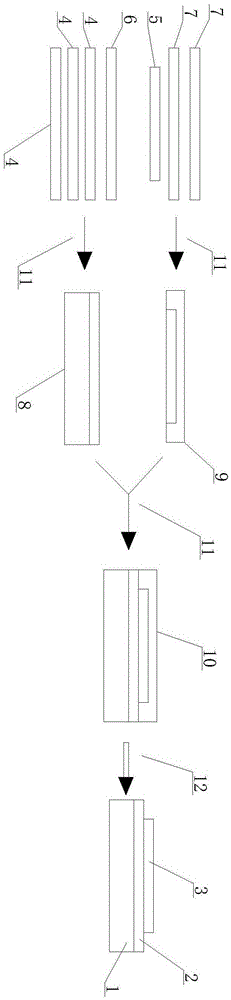

[0027] Specific embodiment one, please refer to figure 1 , an all-solid-state lithium-air battery, characterized in that: the all-solid-state lithium-air battery is composed of a positive electrode layer 1, an electrolyte layer 2 and a negative electrode layer 3, the positive electrode layer 1 is a structural support layer, and the positive electrode layer 1 and The negative electrode layer 3 adopts a large and small structure, the positive electrode layer 1 and the negative electrode layer 3 are separated by the electrolyte layer 2, the thickness of the positive electrode layer 1 is 100um, and the thickness of the electrolyte layer 2 is 5um. The thickness of the negative electrode layer 3 is 5um, the center of the planar size of the positive electrode layer 1, the electrolyte layer 2 and the negative electrode layer 3 coincides, and the planar size of the positive electrode layer 1 is equal to the planar size of the electrolyte layer 2, and the planar size area of the positi...

specific Embodiment 2

[0038] Specific embodiment two, please refer to figure 1 , an all-solid-state lithium-air battery, characterized in that: the all-solid-state lithium-air battery is composed of a positive electrode layer 1, an electrolyte layer 2 and a negative electrode layer 3, the positive electrode layer 1 is a structural support layer, and the positive electrode layer 1 and The negative electrode layer 3 adopts a large and small structure, and the positive electrode layer 1 and the negative electrode layer 3 are separated by an electrolyte layer 2. The thickness of the positive electrode layer 1 is 3000um, and the thickness of the electrolyte layer 2 is 300um. The thickness of the negative electrode layer 3 is 300um, the center of the planar size of the positive electrode layer 1, the electrolyte layer 2 and the negative electrode layer 3 coincides, and the planar size of the positive electrode layer 1 is equal to the planar size of the electrolyte layer 2, and the planar size area of th...

specific Embodiment 3

[0049] Specific embodiment three, please refer to figure 1 , an all-solid-state lithium-air battery, characterized in that: the all-solid-state lithium-air battery is composed of a positive electrode layer 1, an electrolyte layer 2 and a negative electrode layer 3, the positive electrode layer 1 is a structural support layer, and the positive electrode layer 1 and The negative electrode layer 3 adopts a large and small structure, and the positive electrode layer 1 and the negative electrode layer 3 are separated by an electrolyte layer 2. The thickness of the positive electrode layer 1 is 5000um, and the thickness of the electrolyte layer 2 is 500um. The thickness of the negative electrode layer 3 is 500um, the center of the planar size of the positive electrode layer 1, the electrolyte layer 2 and the negative electrode layer 3 coincides, and the planar size of the positive electrode layer 1 is equal to the planar size of the electrolyte layer 2, and the planar size area of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com