Polyphase manganese base solid solution composite cathode material and preparation method thereof

A composite cathode material, solid solution technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of poor rate and low temperature performance, low first coulombic efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

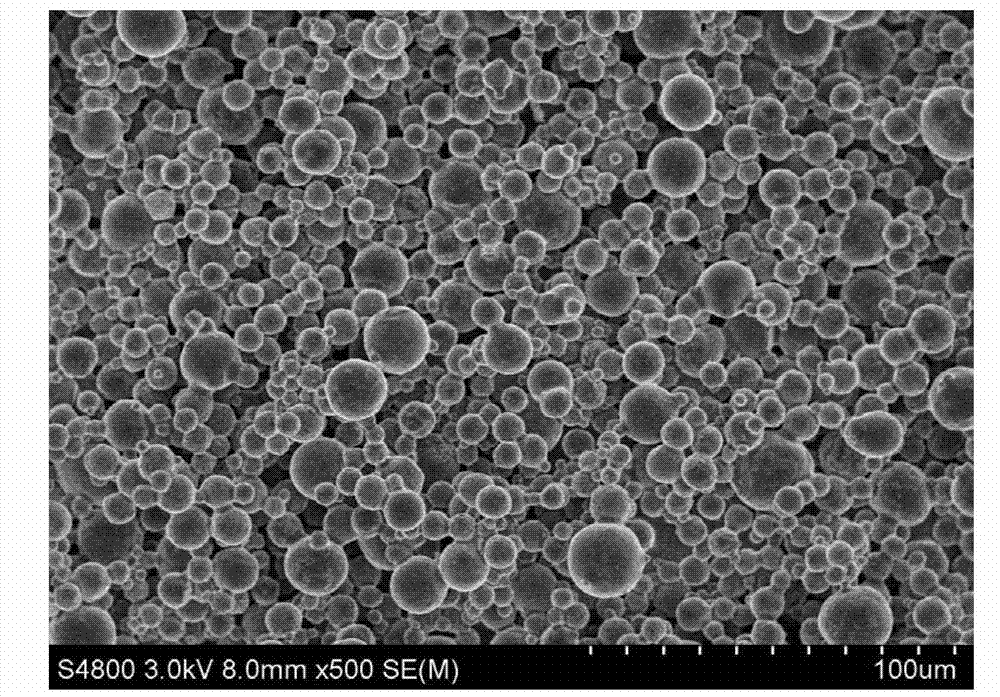

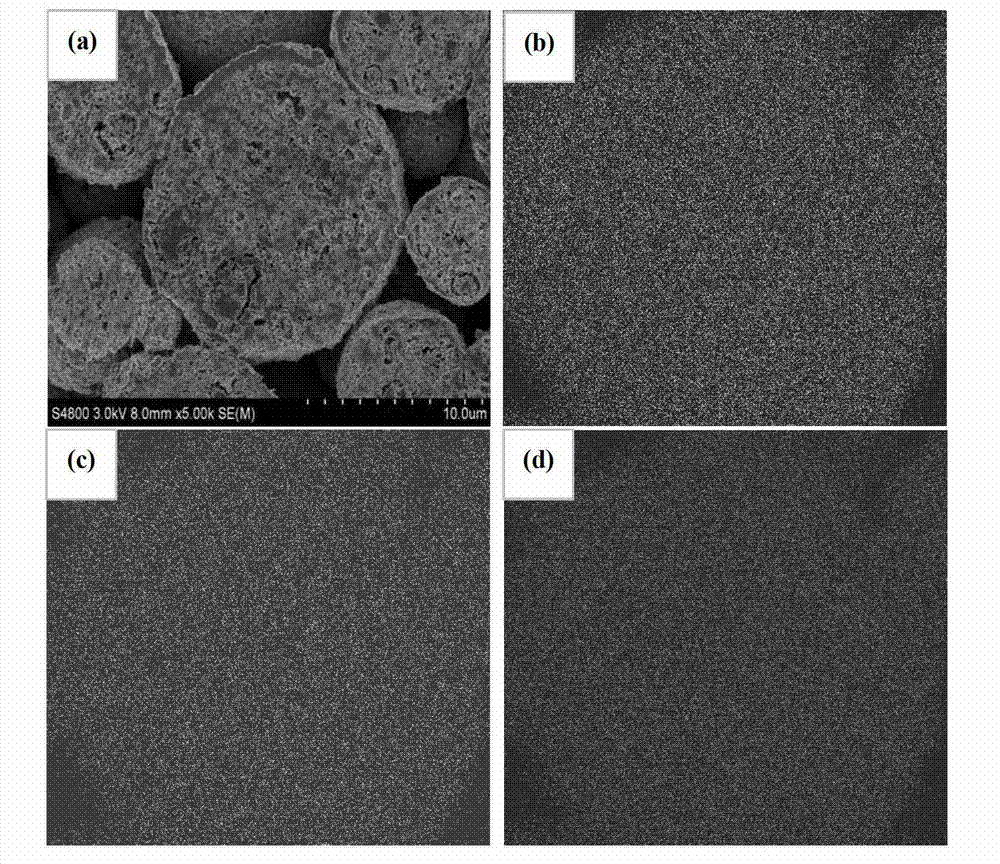

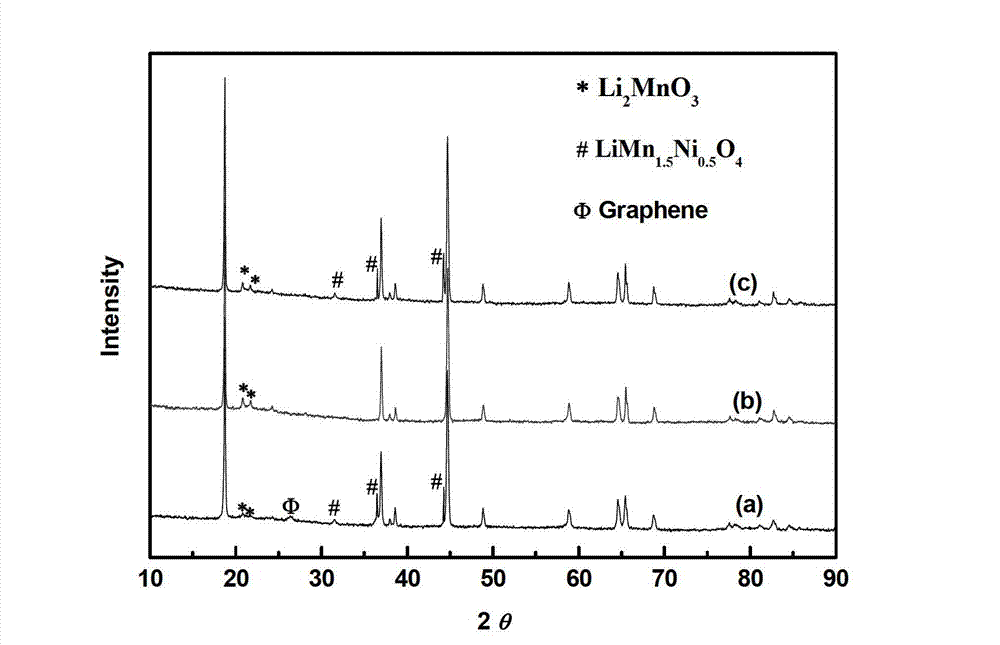

Embodiment 1

[0050]Lithium hydroxide 14mol, manganese nitrate 7mol, nickel nitrate 2mol, cobalt nitrate 1mol are evenly mixed and dispersed in the carboxymethyl cellulose solution, stirred until a suspension is formed; Grinding at a speed of 1 / min for 5 hours to obtain a viscous slurry; use a spray dryer to spray dry the above slurry to obtain a spherical precursor with uniform distribution of three metal elements, manganese, nickel and cobalt; place the precursor in a sintering furnace In the process, the temperature was raised to 950°C at a heating rate of 5°C / min, and the temperature was kept for 10 hours. During the roasting process, dry air was continuously introduced at a flow rate of 20mL / min. Obtain heterogeneous manganese-based solid solution cathode material 0.05LiMn 1.4 Ni 0.4 co 0.2 o 4 0.475 Li 2 MnO 3 0.475LiMn 0.4 Ni 0.4 co 0.2 o 2 ; Take a certain amount of graphene by weighing 2:100 according to the mass ratio of graphene and multiphase manganese-based solid solut...

Embodiment 2

[0052] Lithium hydroxide 13.2mol, manganese nitrate 7mol, nickel nitrate 2mol, cobalt nitrate 1mol are uniformly mixed and dispersed in the PVA aqueous solution, stirred until a suspension is formed; The viscous slurry was obtained by grinding at a rotational speed for 5 hours; the above slurry was spray-dried by a spray dryer to obtain a spherical precursor with uniform distribution of three metal elements, manganese, nickel and cobalt; the precursor was placed in a sintering furnace to The heating rate is 5°C / min, the temperature is raised to 950°C, and the temperature is kept for 10 hours. At the same time, dry air is continuously introduced during the roasting process at a flow rate of 20mL / min. Phase Manganese-Based Solid Solution Cathode Material 0.1LiMn 1.4 Ni 0.4 co 0.2 o 4 0.45 Li 2 MnO 3 0.45LiMn 0.4 Ni 0.4 co 0.2 o 2 . Take a certain amount of graphene by weighing 2:100 according to the mass ratio of graphene and multiphase manganese-based solid solution p...

Embodiment 3

[0054] 11.7mol of lithium hydroxide, 7mol of manganese nitrate, 2mol of nickel nitrate, and 1mol of cobalt nitrate were uniformly mixed and dispersed in the carboxymethyl cellulose solution, and stirred until a suspension was formed. The suspension was transferred to a roller mill jar, and ground at a speed of 400r / min for 5h to obtain a viscous slurry. Use a spray dryer to spray-dry the above slurry to prepare a spherical precursor with uniform distribution of three metal elements, manganese, nickel, and cobalt. Put the precursor in a sintering furnace and raise the temperature to 950 at a heating rate of 5°C / min. ℃, keep warm for 10h, and at the same time, dry air is continuously introduced during the calcination process at a flow rate of 20mL / min. After calcination, it is naturally cooled to room temperature, and the multiphase manganese-based solid solution positive electrode material 0.2LiMn is obtained by crushing, grading, and sieving. 1.4 Ni 0.4 co 0.2 o 4 0.4 Li 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com