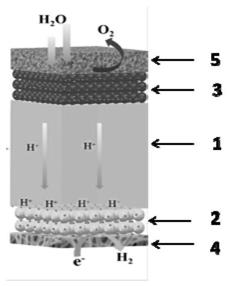

Membrane electrode assembly for solid polymer electrolyte electrolytic cell and preparation method

A solid polymer, membrane electrode assembly technology, applied in the direction of electrolysis components, electrodes, electrolysis process, etc., to achieve the effect of reducing ohmic impedance, reducing interface contact impedance, and reducing use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

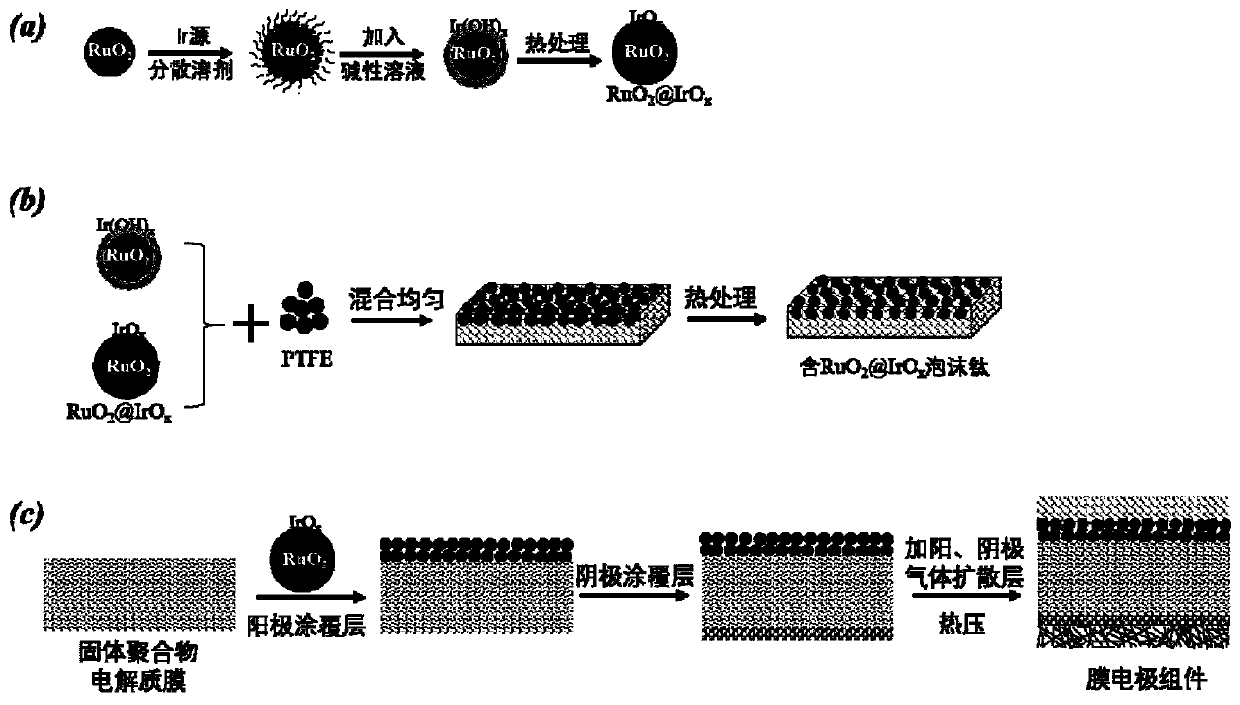

[0029] like figure 2 As shown in (a), 0.075g RuO 2 Added 200ml ethanol solution ultrasonic 30min, 0.025g IrCl 3 Join RuO 2 Continue to sonicate for 30 minutes, then add 0.01M NaOH aqueous solution drop by drop until the pH of the mixed solution is ≥ 10 and keep for two hours. Process 1h to get RuO 2 @IrO x core-shell material.

[0030] like figure 2 (b) shows the resulting RuO 2 @IrO x Mixed with polytetrafluoroethylene (PTFE) according to the mass ratio of 70:30 mechanical ball milling, coated on the surface of foamed titanium, and then treated at 350 ° C for 1 h to obtain the RuO-containing 2 @IrO x Titanium foam, RuO on the surface of titanium foam 2 @IrO x The loading capacity is 0.05mg cm -2 ;

[0031] RuO 2 @IrO x And 5% Nafion solution is dispersed in the mixed solution (isopropanol: water=9:1) of isopropanol water according to mass ratio (80:20) and stirs to obtain slurry, by screen printing method RuO 2 @IrO x Prepared on Nafion 117 as the anode cat...

Embodiment 2

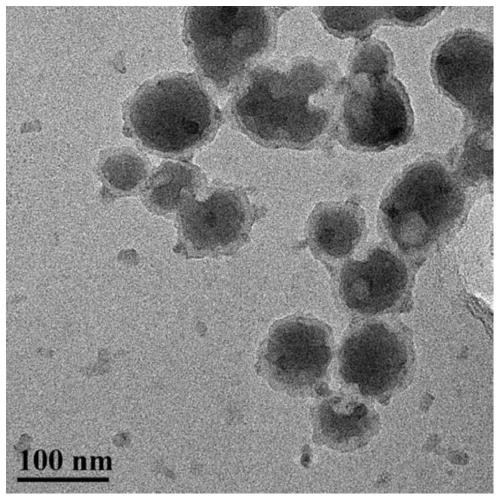

[0033] 0.075g RuO 2 Added 180ml of ethanol and 20ml of water in the mixed solution of ultrasonic 30min, 0.025g H 2 IrCl 6 6H 2 O joined RuO 2 The ethanol-water mixed solution, continue to sonicate for 30min, then add ammonia aqueous solution drop by drop, until the mixed solution is maintained at pH = 12 for two hours, collect the resulting precipitate, place it in a vacuum oven for drying at 80°C, and then dry it in a vacuum oven at 400°C Treat at ℃ for 1h to get RuO 2 @IrO x core-shell material. image 3 For the prepared RuO 2 @IrO x For the core-shell sample, it can be seen that the RuO 2 The size of the core is about 85nm, and the outer shell is IrO x About 8nm.

[0034] The RuO obtained above 2 @IrO x The dried precursor precipitate was mixed with polytetrafluoroethylene (PTFE) by mechanical ball milling according to the mass ratio of 80:20, and then coated on the surface of titanium foam, and then treated at 350°C for 2h to obtain the RuO-containing 2 @IrO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com