Solid-state electrolyte, preparation method thereof and solid-state battery

A solid-state electrolyte, solid-state battery technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, solid electrolytes and other directions, can solve the problem that the electrode plates cannot obtain cycle performance and rate performance, and cannot exert the maximum benefit of solid-state batteries, etc., to improve Insufficient stability, effect of improved ionic conductivity, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

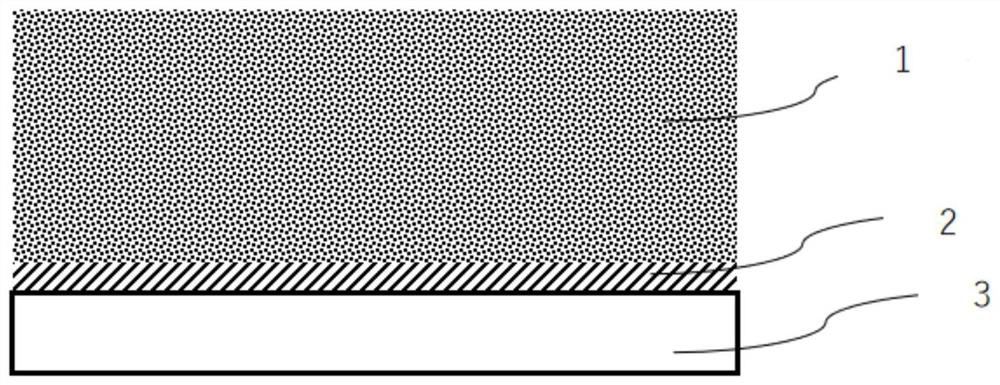

Image

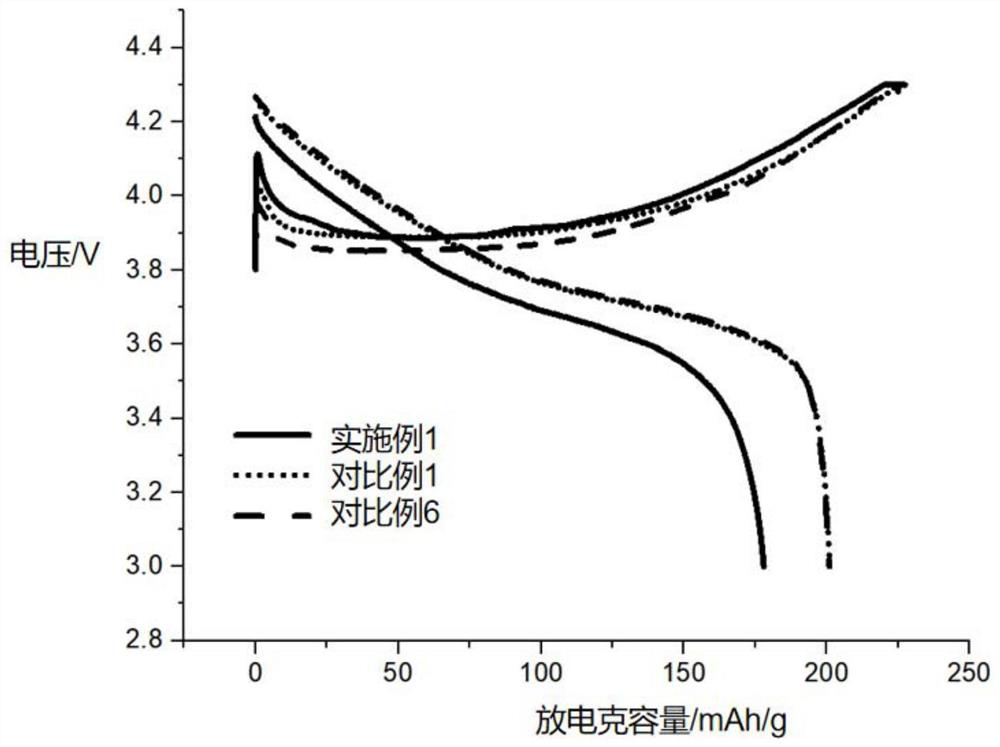

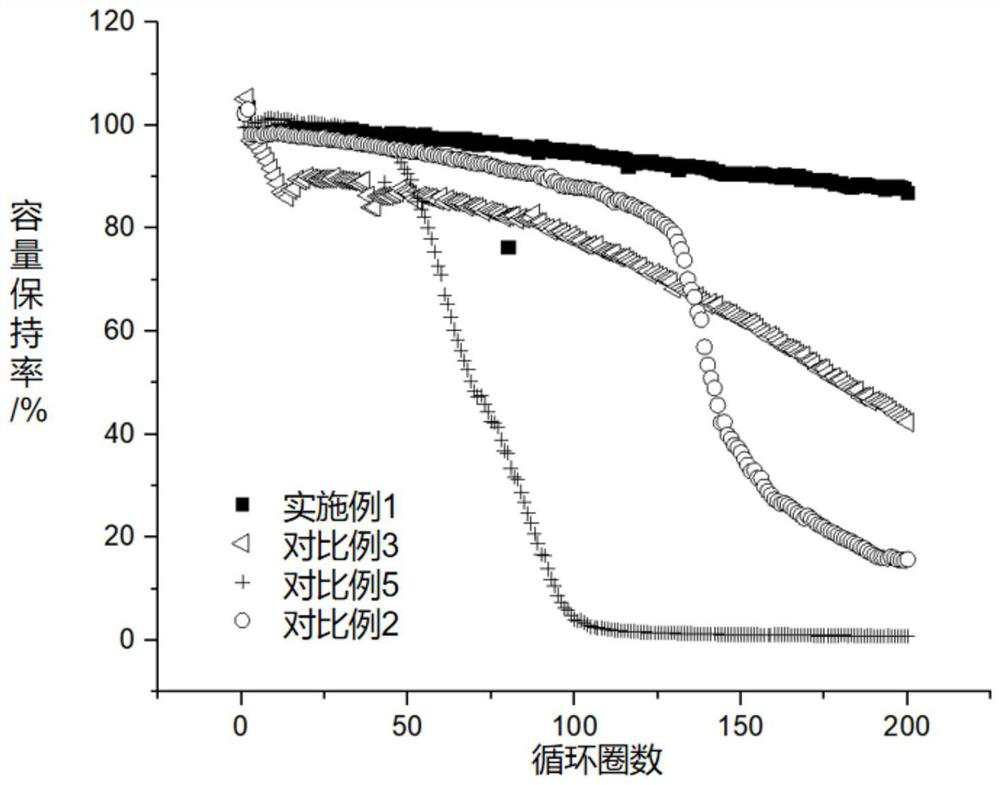

Examples

preparation example Construction

[0032] 1. Preparation of solid electrolyte:

[0033] According to the composition design in Table 2, the base polymer and the dopant were mixed at a mass ratio of 5:1, and then the mixture was placed in an argon atmosphere and heated at 200°C for 24 hours. After cooling, it was ground to reduce the particle size of the material to 50 μm. Left and right, get the polymer ion conductor, spare;

[0034] The ceramic-based ion conductor was put into a ball mill and milled at a speed of 1000 rpm for 8 hours to make the particle size as small as about 500nm. The mixture composed of ceramic-based ion conductor, polymer ion conductor and lithium salt is dissolved in DMF, stirred evenly, and coated on the surface of aluminum foil. After the solvent is volatilized, a solid electrolyte with a thickness of 50 μm is obtained; Table 2 shows the composition and performance parameters of the solid electrolyte. For the lithium salt composition, the mass ratio of LiTFSI and LiDFOB in the lithium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com