Method for preparing titanium dioxide thin films through room temperature sputtering method

A titanium dioxide and sputtering technology, which is used in sputtering coating, semiconductor/solid-state device manufacturing, vacuum evaporation coating, etc., can solve the problems of harsh conditions and high synthesis temperature, and achieves reduced interface resistance, simple preparation process, and thickness. Continuously adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Compared with traditional preparation methods, perovskite solar cells based on this thin film have higher fill factor and short-circuit current, and the photoelectric conversion efficiency of the cell is higher. The room temperature sputtering method not only simplifies the traditional battery preparation process and saves costs, but also can improve the performance of the thin-film battery, which is conducive to promoting the market application of perovskite solar cells.

[0045] Advantages of the invention;

[0046] The film preparation conditions are mild, the equipment is simple, and resources and energy are saved;

[0047] The magnetron sputtering method has a short preparation period and can be continuously controlled, not limited by the substrate size and film uniformity;

[0048] The preparation process of the magnetron sputtering method is simple, high stability, good repeatability, and the market application prospect is bright;

[0049] The titanium dioxide ...

Embodiment 1

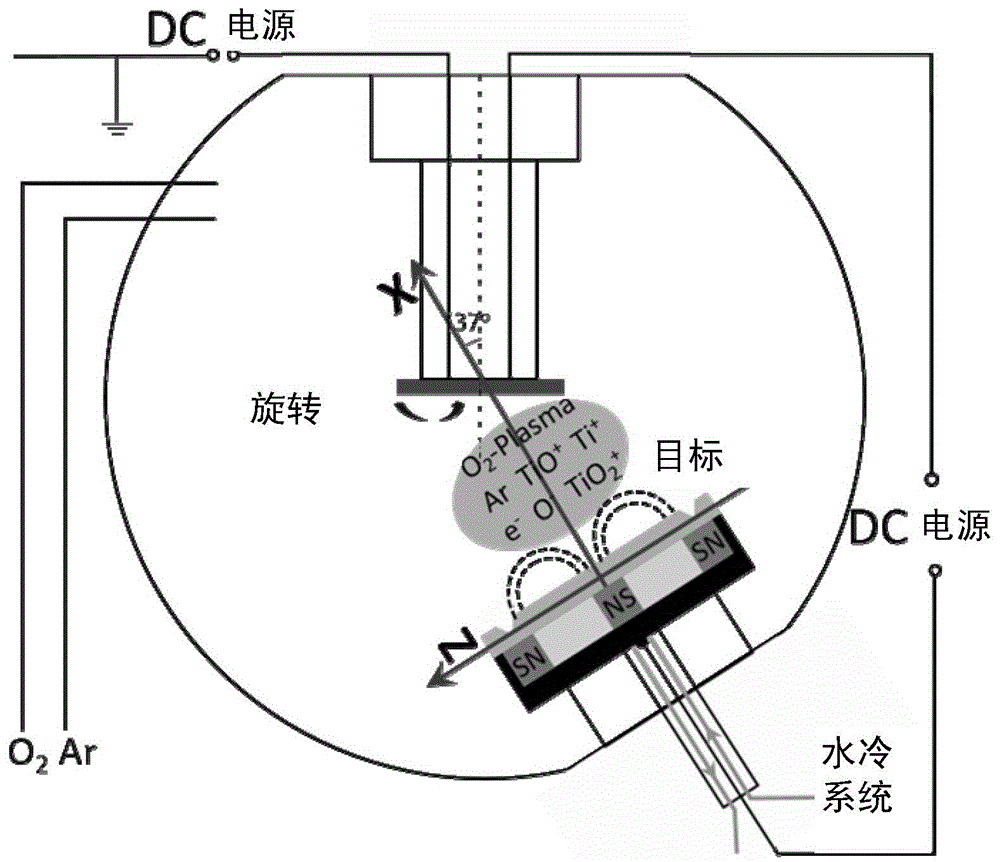

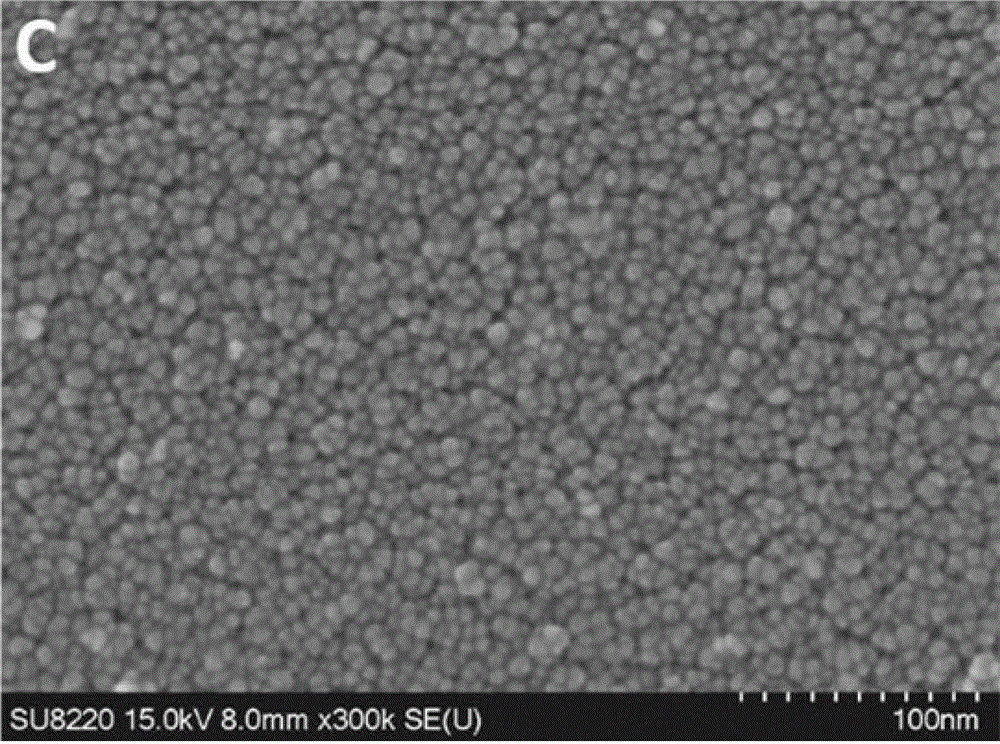

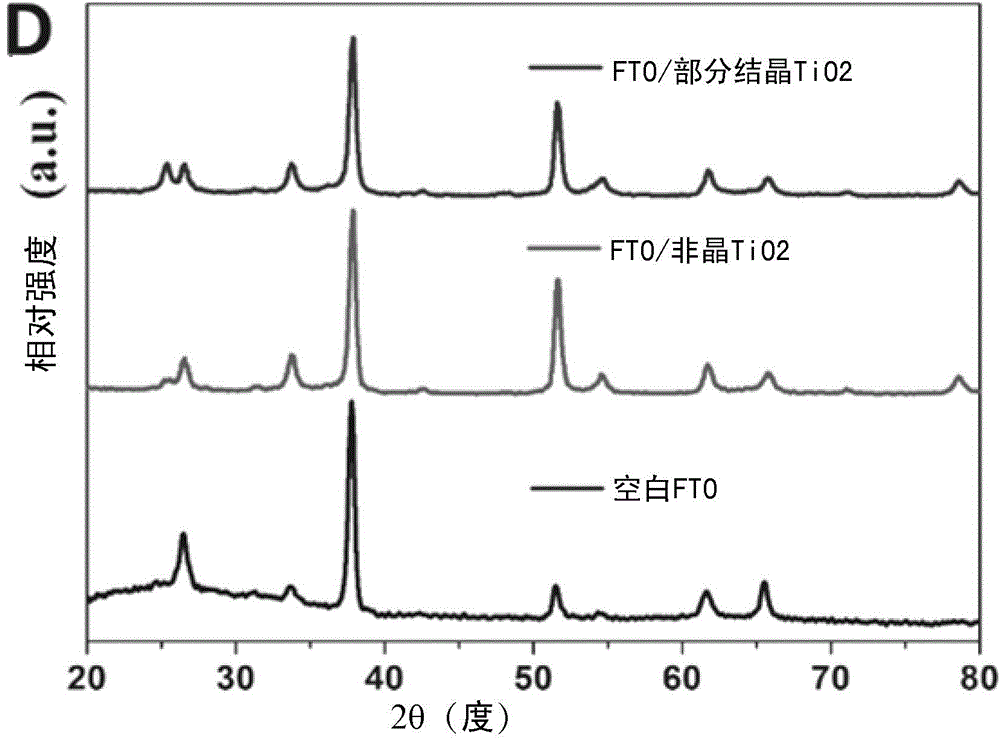

[0052] The substrate (FTO glass) was ultrasonically cleaned, and after the substrate was ultrasonically cleaned with acetone and absolute ethanol for 30 minutes, it was fixed on the substrate plate in an orderly manner, put into the sample chamber, and then opened the gate and loaded to a vacuum degree ( background vacuum) has reached 10 -4 In the deposition chamber below Pa. Introduce oxygen and argon at a ratio of 1:6, control the total pressure to 1.5Pa, the distance between the target and the substrate is 8cm, and the initial chamber temperature is kept at room temperature (15-35°C) and the DC power supply ( Electric power is 675W), sputtering pure titanium target material, deposition time is 15min, obtains completely amorphous titanium dioxide thin film, as Figure 2D shown. Subsequently, the perovskite absorber material was prepared by vacuum evaporation, the hole transport material was prepared by spin coating, and the back electrode (Ag) was prepared by vacuum evapor...

Embodiment 2

[0054] The substrate (FTO glass) was ultrasonically cleaned, and after the substrate was ultrasonically cleaned with acetone and absolute ethanol for 30 minutes, it was fixed on the substrate plate in an orderly manner, put into the sample chamber, and then opened the gate and loaded to a vacuum degree ( background vacuum) has reached 10 -4 In the deposition chamber below Pa. Introduce oxygen and argon at a ratio of 1:6, control the total pressure at 1.5Pa, and keep the distance between the target and the substrate at 8cm. The initial chamber temperature is kept at room temperature and the DC power supply (electric power is 700W) is turned on. Sputtering The pure titanium target is irradiated, and the deposition time is 15min, and a partially crystallized titanium dioxide film is obtained, and the XRD pattern is as follows Figure 2D Shown, according to crystallinity empirical formula:

[0055] R = X / Y ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com