Interface wetting agent and preparation method and application thereof

A technology of interfacial wetting and additives, which is applied in the field of materials, can solve the problems that the interface reaction impedance cannot be improved, the interface electrochemical stability is very poor, and the interface resistance problem needs to be improved, so as to achieve good electrochemical stability and reduce the interface reaction impedance , high security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

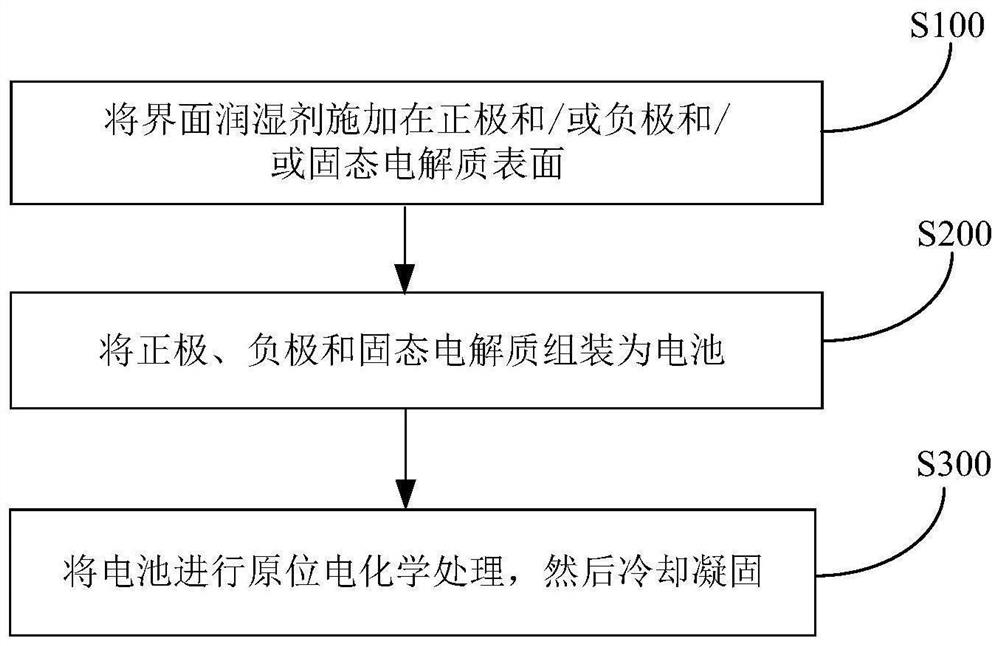

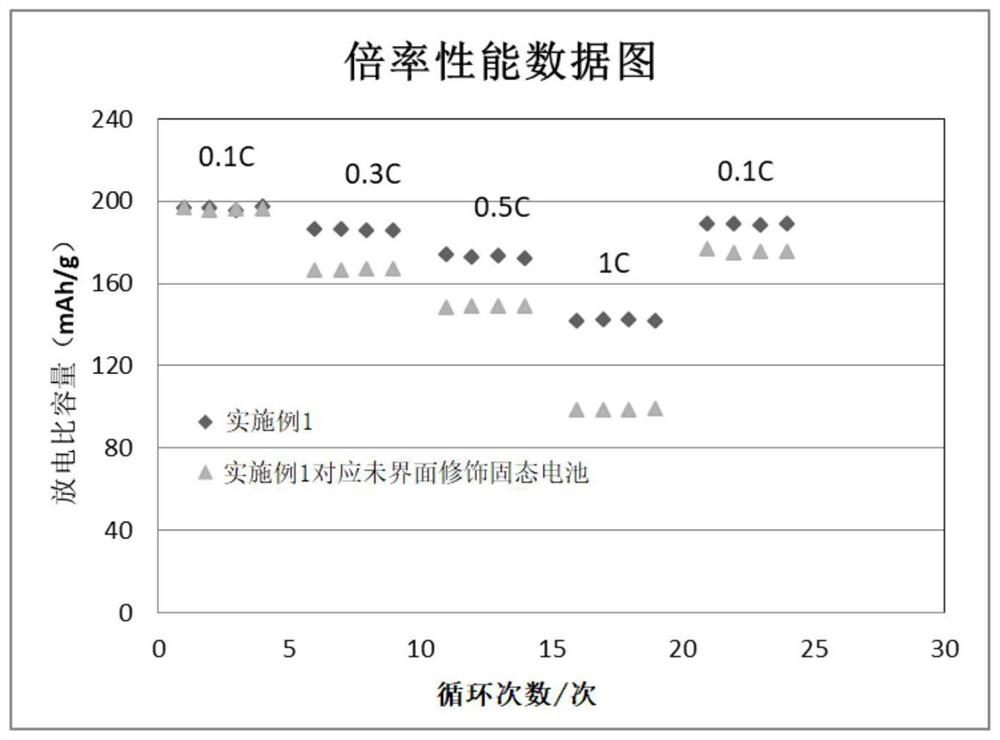

[0062] According to the method for preparing a solid-state battery according to an embodiment of the present invention, the above-mentioned interfacial wetting agent having the advantages of high lithium ion conductivity and better electrochemical stability is applied to the surface of the positive electrode and / or the negative electrode and / or the solid electrolyte, and then Assembled into a battery, that is, an interfacial wetting layer formed by an interfacial wetting agent is formed between the positive electrode and the solid electrolyte and / or between the negative electrode and the solid electrolyte, and finally in-situ electrochemical treatment is performed. On the one hand, the interfacial wetting agent The synergistic effect of the first additive and the second additive can generate a nanoscale and stable interface modification layer on the surface of the positive electrode and / or the surface of the negative electrode and / or the surface of the solid electrolyte, thereby...

Embodiment 1

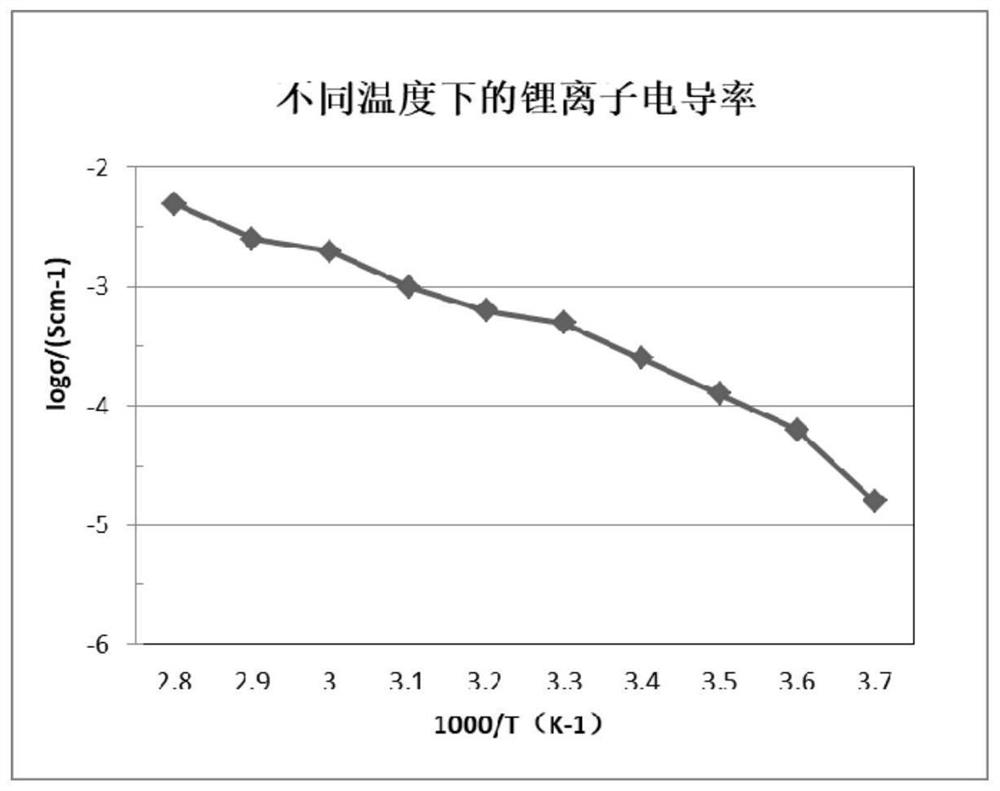

[0066] Choose LiNi 0.8 co 0.1 mn 0.1 It is the positive electrode active material of the solid-state battery, graphite is the negative electrode active material, and the positive electrode and the negative electrode of the solid-state battery are prepared, and the garnet-type oxide electrolyte LLZO is selected as the solid electrolyte. Take by weighing 55wt% succinonitrile, the first additive of 42wt% (the first additive is ethylene carbonate, diethyl carbonate and dimethyl carbonate (volume ratio of ethylene carbonate, diethyl carbonate and dimethyl carbonate) 1:1:1)), 3wt% vinylene carbonate is the second additive, and the bistrifluoromethanesulfonimide lithium with a concentration of 1.5mol / L is an inorganic lithium salt. Heat and stir for 16 hours, and mix evenly to obtain an interface wetting agent. The obtained interfacial wetting agent was printed on the surface of the positive and negative electrodes of the solid-state battery, and assembled into a solid-state batte...

Embodiment 2

[0068] Choose LiNi 0.6 co 0.2 mn 0.2 It is the positive electrode active material of the solid-state battery, silicon carbon is the negative electrode active material, and the positive electrode and the negative electrode of the solid-state battery are prepared, and LGPS sulfide is selected as the solid-state electrolyte. Weigh 85wt% of the plastic crystal compound (the cation is N,N-methylpropylpyrrolidine, and the anion is PF 6 - ), 14.1wt% of the first additive (the first additive is ethylene carbonate and ethyl methyl carbonate, the volume ratio between the two is 3:7), 0.3wt% propylene sulfite, 0.6wt% of 1, 2-bis(cyanoethoxy)ethane is the second additive, and lithium hexafluorophosphate with a concentration of 1mol / L is the inorganic lithium salt. The above raw materials are heated and stirred at 45°C for 12 hours and mixed evenly to obtain a positive electrode interface wetting agent; at the same time, the plastic The addition amount and type of crystalline compound,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com