Photoluminescent coating material composition

A technology of composition and brightness, applied in polyester coatings, coatings, devices for coating liquids on surfaces, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

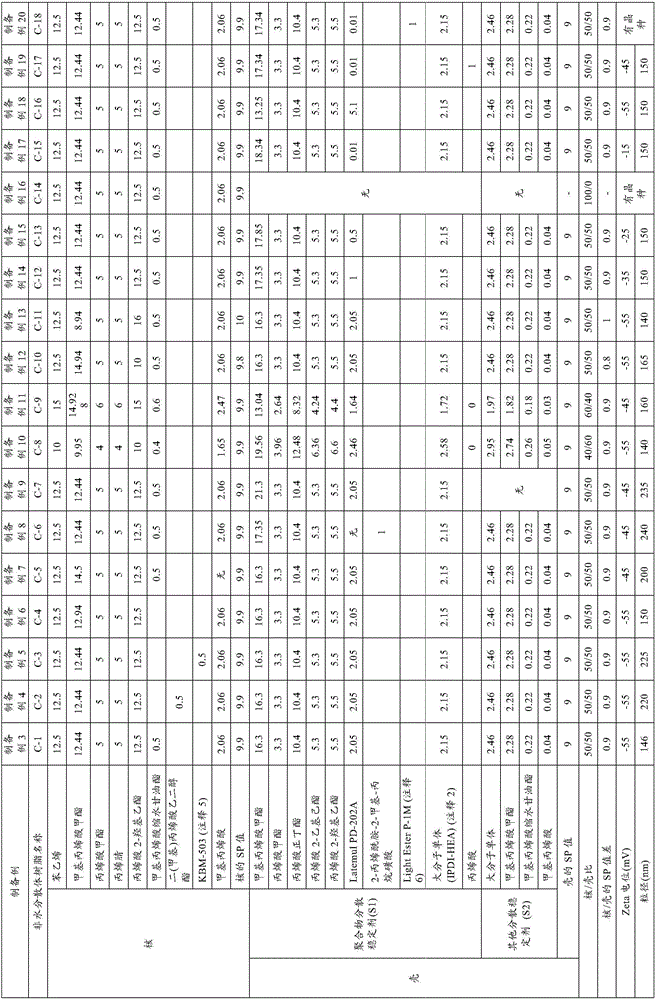

Examples

preparation example Construction

[0091] The preparation method of the hydroxyl group-containing polyester resin (A2) is not limited, and can be performed by any conventional method. For example, the acid component and the alcohol component are heated at about 150° C. to 250° C. for about 5 hours to 15 hours in a nitrogen stream to perform esterification or transesterification of the acid component and the alcohol component. Thereby, a hydroxyl-containing polyester resin can be prepared.

[0092] For the esterification or transesterification of an acid component and an alcohol component, these components may be added to the reaction vessel at one time, or one or both of the components may be added in several portions. In addition, a hydroxyl group-containing polyester resin may be synthesized first and then subjected to a half-esterification reaction with an acid anhydride to thereby obtain a carboxyl group- and hydroxyl group-containing polyester resin. In addition, a carboxyl group-containing polyester resi...

Embodiment

[0229] The present invention is described in more detail below with reference to Examples and Comparative Examples; however, the present invention is not limited to these Examples. In the following examples, "part" and "%" are based on mass.

[0230] Preparation of hydroxyl-containing acrylic resin (A1) solution

preparation example 1

[0232] 30 parts of Swasol 1000 (trade name, produced by Maruzen Petrochemical Co., Ltd.; petroleum-based aromatic hydrocarbon solvent) were placed in a tank equipped with a thermometer, thermostat, stirrer, reflux condenser, nitrogen inlet tube and dropping funnel In a reaction vessel, it was heated to 110° C. while nitrogen was blown in. Subsequently, a polymerizable monomer solution containing 10 parts of styrene, 50 parts of methyl methacrylate, 28 parts of n-butyl acrylate, 4 parts or less of phosphoric acid group-containing monomers and 1.5 parts of 2,2'-azobisiso A monomer mixture of butyronitrile (AIBN) was added dropwise to the reaction vessel maintained at the same temperature over 4 hours. After completion of the dropwise addition, the mixture was aged for 1 hour. Subsequently, a mixture of 15 parts of butyl acetate and 1.0 part of 2,2'-azobisisobutyronitrile was further added dropwise into the reaction vessel over 1 hour. After the dropwise addition was completed,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com