High-performance foam concrete insulation board and preparation method thereof

A technology of foam concrete and insulation board, applied in the field of building exterior wall insulation materials, can solve the problems of foam pore size and uneven distribution, difficulty in guaranteeing construction and strength, unreasonable structure components of pore walls, etc., and reduce water absorption , high waterproof effect, the effect of reducing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

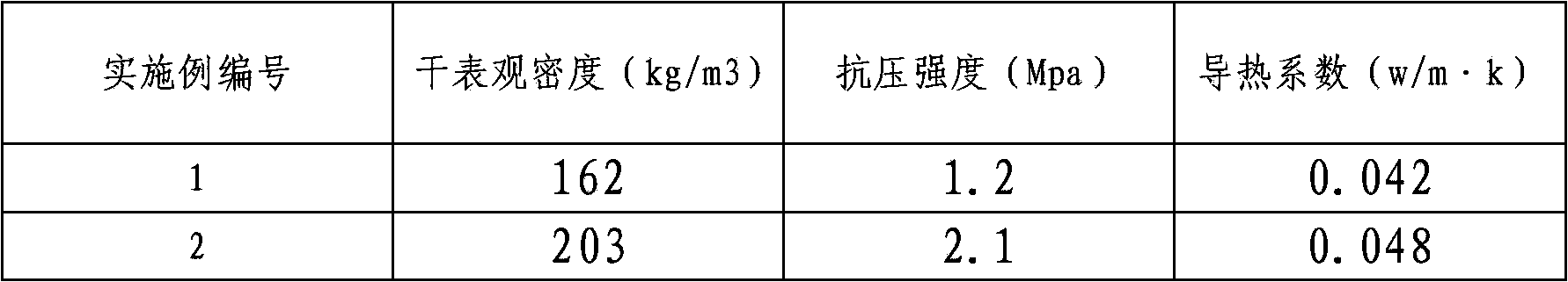

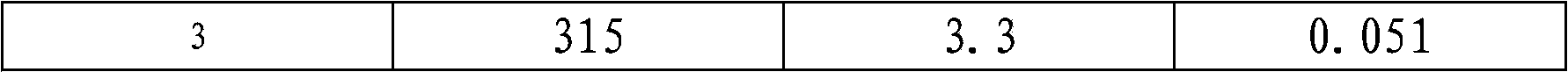

Embodiment 1

[0023] High-performance foam concrete insulation board, weigh 65kg of cement, 55kg of admixture, 15kg of foaming agent, 52kg of water, 1.1kg of admixture, and 2.0kg of modifier. After mixing, pouring, pre-setting and demoulding, curing.

[0024] Preparation of high-performance foam concrete insulation board Mix 65kg of cement, 55kg of admixture, 52kg of water, 1.1kg of admixture and 2.0kg of modifier, stir at 40r / min for 3min and mix evenly, then add 15kg of foaming agent and Mix and stir at a rate of 100r / min for 1min, pour the material into the mold, and enter the pre-condensation kiln. Curing to form foam concrete insulation board.

[0025] The above-mentioned cement is Jianba brand P.O52.5 ordinary Portland cement produced by Liaoning Zhongbei Cement; Mineral powder and fly ash in the mixture are mixed in a ratio of 1:1 by weight; the foaming agent is industrial hydrogen peroxide with a mass concentration of 27.5%; the admixture is produced by Shenyang Yilida Construction...

Embodiment 2

[0027] High-performance foam concrete insulation board, weigh 90kg of cement, 80kg of admixture, 20kg of foaming agent, 68kg of water, 1.6kg of admixture, and 3.0kg of modifier. After mixing, pouring, pre-setting and demoulding, curing.

[0028] Preparation of high-performance foam concrete insulation board: Mix 90kg of cement, 80kg of admixture, 68kg of water, 1.6kg of admixture and 3.0kg of modifier, and stir at 40r / min for 3min to mix evenly, then add 15kg of foaming agent and Mix and stir at a rate of 100r / min for 1min, pour the material into the mold, and enter the pre-condensation kiln. Cut and maintain to form a foam concrete insulation board.

[0029] The above-mentioned cement is Jianba brand P.O42.5 ordinary portland cement produced by Liaoning Zhongbei Cement; Mineral powder and fly ash in the mixture are mixed in a ratio of 2:1 by weight; the foaming agent is industrial hydrogen peroxide with a mass concentration of 27.5%; the admixture is produced by Shenyang Yil...

Embodiment 3

[0031] High-performance foam concrete insulation board, weighing 130kg of cement, 120kg of admixture, 21kg of foaming agent, 98kg of water, 2.0kg of admixture, and 3.6kg of modifier, after mixing, pouring, pre-setting, formwork removal, and curing.

[0032]Preparation method of high-performance foam concrete insulation board: mix 130kg of cement, 120kg of admixture, 98kg of water, 2.0kg of admixture and 3.6kg of modifier, stir at 40r / min for 3min and mix evenly, then add 15kg of foaming agent and mix Mix and stir at a rate of 100r / min for 1min, pour the material into the mold, and enter the pre-condensation kiln. Cut and maintain to form a foam concrete insulation board.

[0033] The above-mentioned cement is Jianba brand P.O42.5 ordinary portland cement produced by Liaoning Zhongbei Cement; Mineral powder and fly ash in the mixture are mixed in a ratio of 2:1 by weight; the foaming agent is industrial hydrogen peroxide with a mass concentration of 27.5%; the admixture is pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com