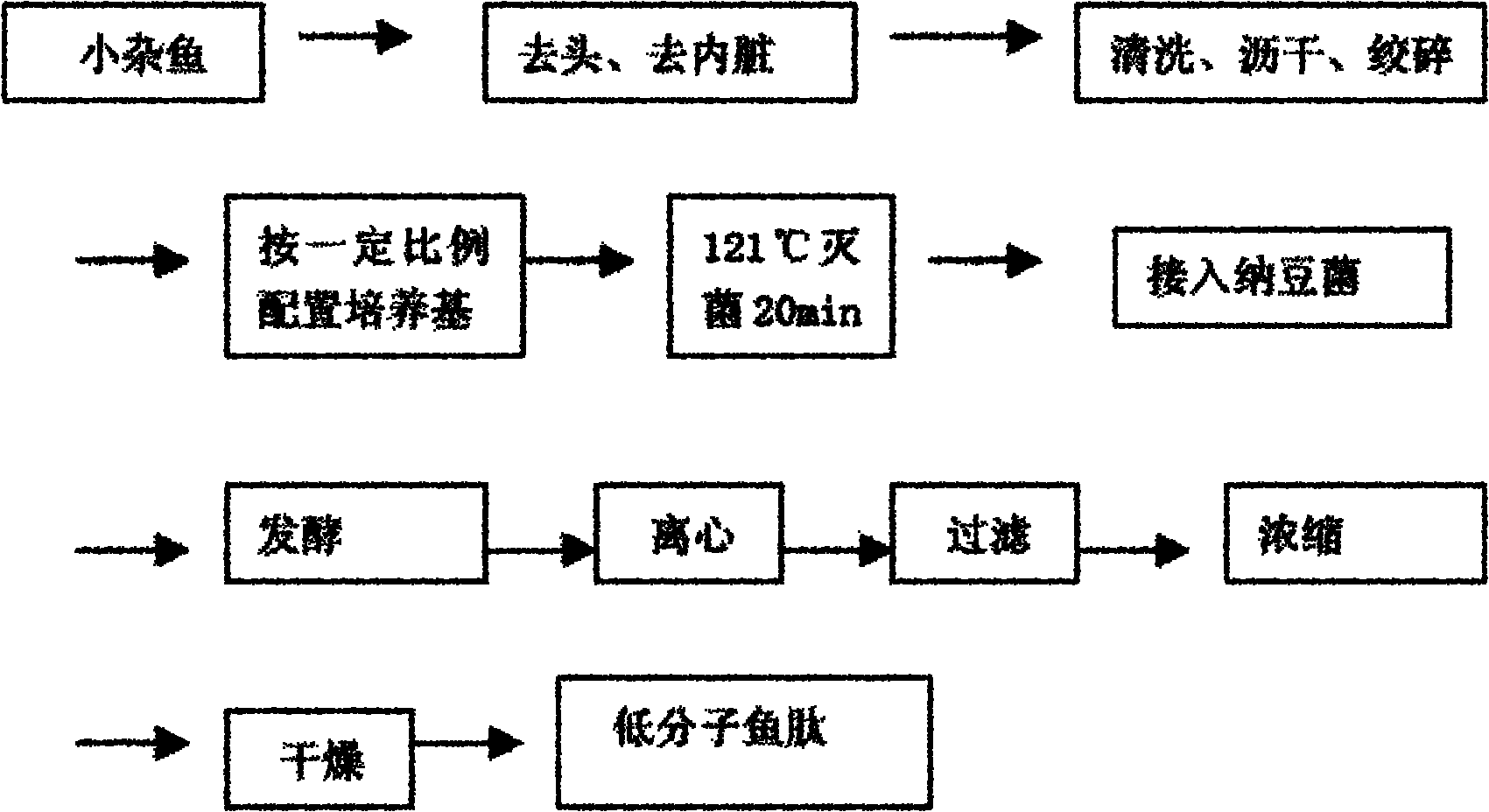

Method for preparing low molecular weight fish peptide through Bacillus natto fermentation method

A low-molecular, natto-based technology is applied in food preparation, protein food ingredients, and fish protein ingredients. It can solve problems such as low fish prices, poor transportation and sales, and discard leftovers, achieving flexibility, High protein content, good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Example 1: Take 100kg of minced fish, add 400L of water, 8kg of glucose, adjust the pH to 6.5, sterilize by high-pressure steam at 121°C for 20min, add 12L of Bacillus natto seed solution after cooling, and cultivate in ventilation at 32°C for 48h. The fermentation broth was centrifuged at 4000r / min for 20min, the filtrate was concentrated, dried and pulverized to obtain 15.4kg of low molecular weight fish peptide product.

example 2

[0019] Example 2: Take 120kg of minced fish, add 480L of water, 9.6kg of sucrose, adjust the pH to 7.5, sterilize by high pressure steam at 121°C for 20min, add 14.4L of Bacillus natto seed liquid after cooling, and cultivate in ventilation at 37°C for 36h. The fermentation broth was centrifuged at 4000r / min for 20min, the filtrate was concentrated, dried and pulverized to obtain 18.6kg of low-molecular-weight fish peptide product.

example 3

[0020] Example 3: Take 150 kg of minced fish, add 600 L of water, 12 kg of sucrose, adjust the pH to 7.0, sterilize by high-pressure steam at 121°C for 20 minutes, add 18L of Bacillus natto seed liquid after cooling, and cultivate in ventilation at 40°C for 60 hours. The fermentation broth was centrifuged at 4000r / min for 20min, the filtrate was concentrated, dried and pulverized to obtain 23.7kg of low-molecular-weight fish peptide product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com