Plate putting machine for fireproof plate production line

A fireproof board and production line technology, applied in the direction of supply devices, pressing rollers, manufacturing tools, etc., can solve the problems of low production efficiency and low yield of fireproof boards, and achieve the effects of improving quality, improving production quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

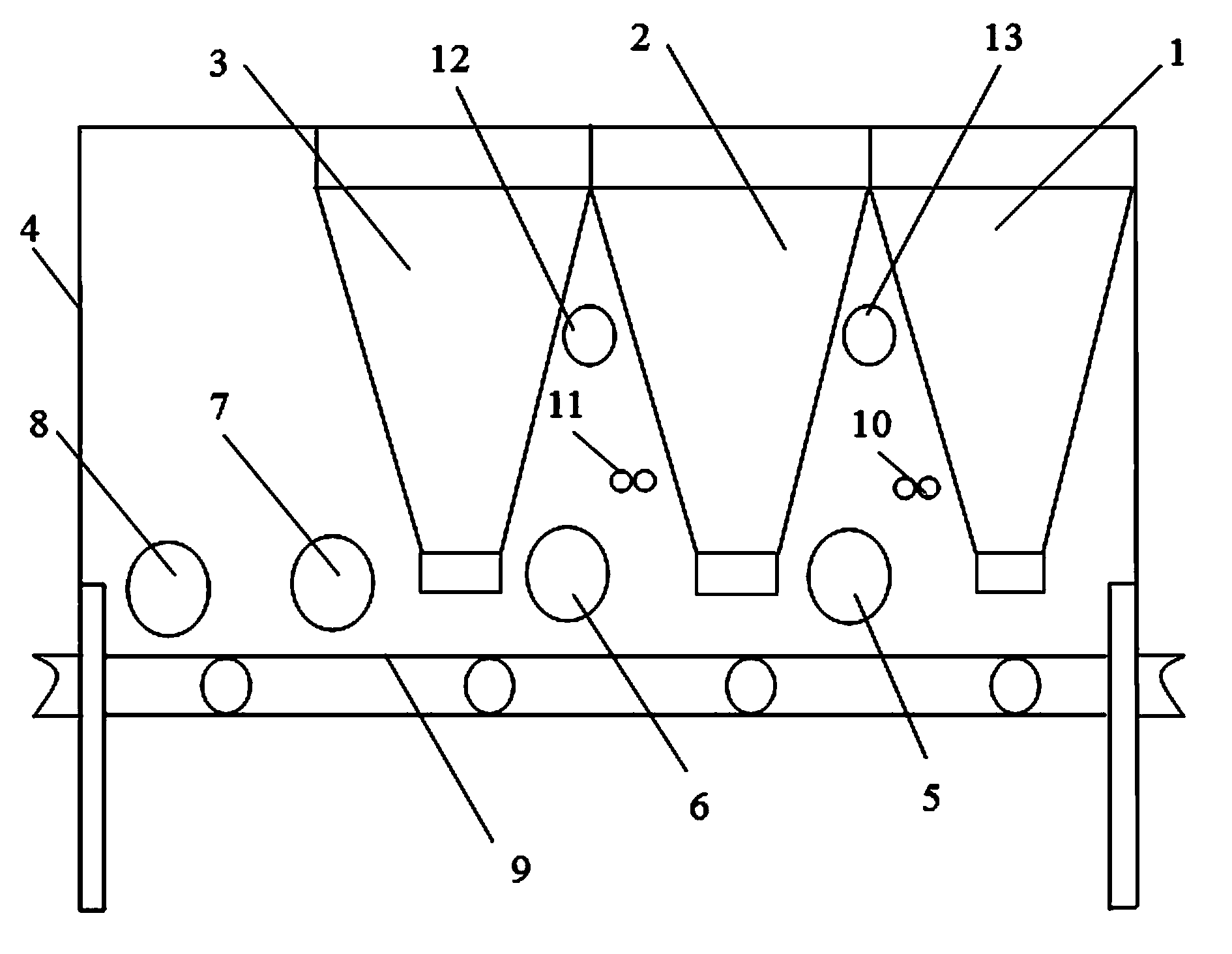

Embodiment 1

[0022] Embodiment 1: A board-setting machine for processing three-layer solid fireproof boards. like figure 1 As shown, a hopper and a pressure roller shaft are arranged on the top of the material row conveyor belt 9, and the shaft seats of the hopper and the pressure roller shaft are all fixed with the frame 4, and along the running direction of the material row conveyor belt, the first The hopper 1, the second hopper 2 and the third hopper 3 are equipped with two stirring shafts in the first hopper, the second hopper, and the third hopper. During implementation, the stirring shaft adopts a wing-shaped roller whose outer surface is wing-shaped. A first press roller shaft 5 is provided between the first hopper 1 and the second hopper 2, a second press roller shaft 6 is provided between the second hopper 2 and the third hopper 3, and a third press roller shaft 6 is provided on the rear side of the third hopper 3. The pressing roller shaft 7, the first pressing roller shaft 5, ...

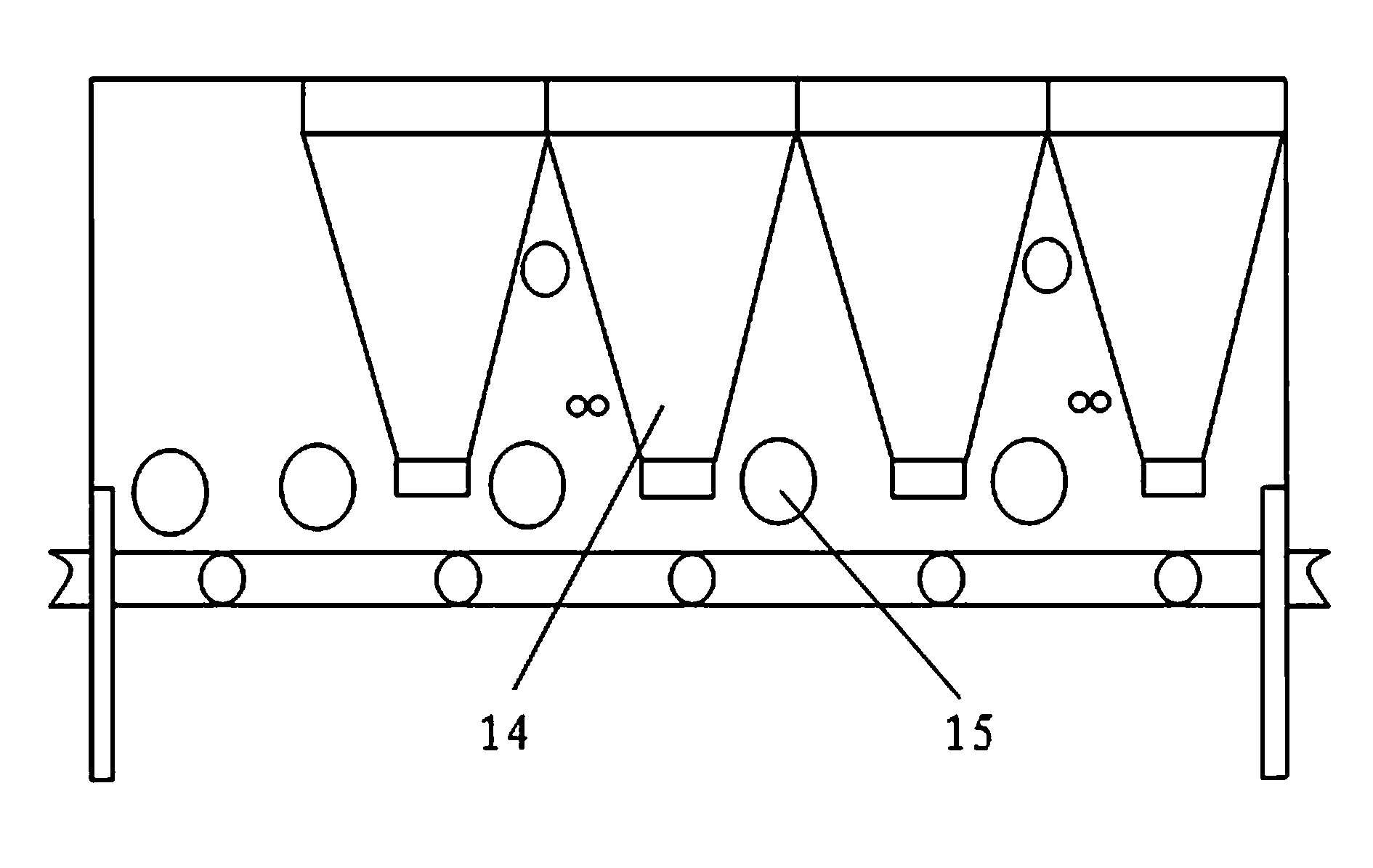

Embodiment 2

[0026] Embodiment 2: A board-setting machine for processing three-layer hollow fireproof boards. like figure 2 As shown, the difference with the structure of Embodiment 1 is that a fourth hopper 14 is added between the second hopper and the third hopper, and a fifth press roller shaft 15 is added between the fourth hopper 14 and the second hopper. , the processing of the second layer of the fireproof board is realized by two pressing roller shafts, the fifth pressing roller shaft 15 is used to process the lower half of the hollow layer (the second layer of the fireproof board), and the second pressing roller shaft behind is used for processing The upper half of the hollow layer (the second layer of the fireproof board). At the same time, since the thickness of the hollow fireproof board is greater than that of the solid fireproof board, the distance between the high-pressure roller shaft and the top surface of the material row should be adjusted accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com