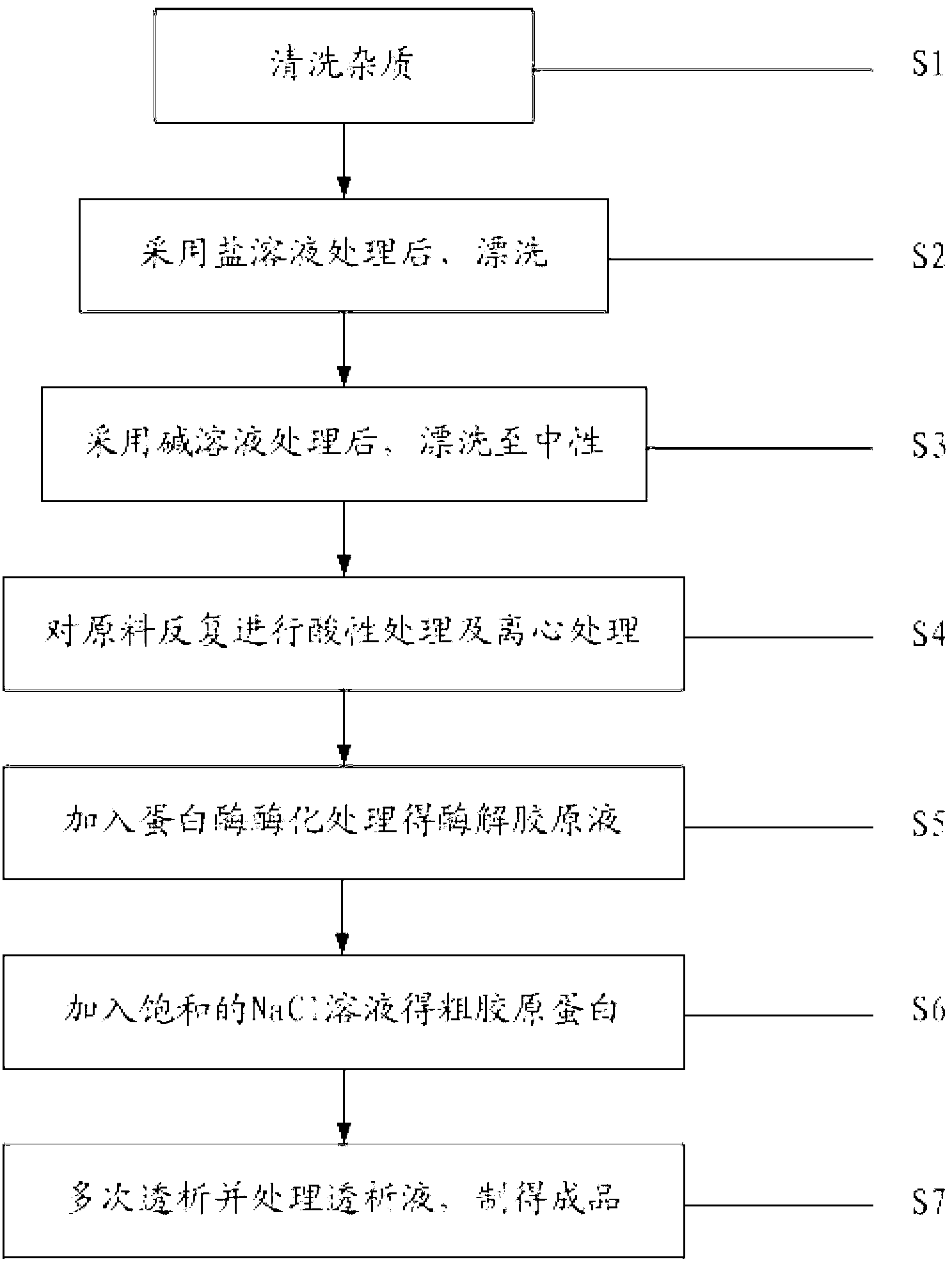

Preparation method of fish-skin collagen for medical biomaterial

A biomaterial and fish skin technology, applied in the preparation methods of peptides, chemical instruments and methods, animal/human proteins, etc., can solve the problems of polluted environment, long processing time, undiscovered, etc., and achieve good biocompatibility, The effect of short processing times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take 200g of fresh cod skin, remove the residual meat and fat, cut it into 1cm×1cm small pieces with a slicer, rinse with 20 times 4°C pure water for 30 minutes, repeat once, and drain. Put the fish skin in 3% NaCl solution at 4°C, the ratio of solid to liquid is 1:30 (w / w), stir for 40 hours, change the liquid every 10 hours, and drain. Wash with deionized water at 4°C 1:20 (w / w) 4 times, 30 minutes each time, and drain the water.

[0035]Put the fish skin in 0.2M NaOH solution at 4°C, the ratio of solid to liquid is 1:30 (w / w), stir for 40 hours, change the solution every 10 hours, and drain. Wash with deionized water at 4°C (1:30w / w) for 3 times, each time for 1 hour, until the pH is 7-8, and drain the water.

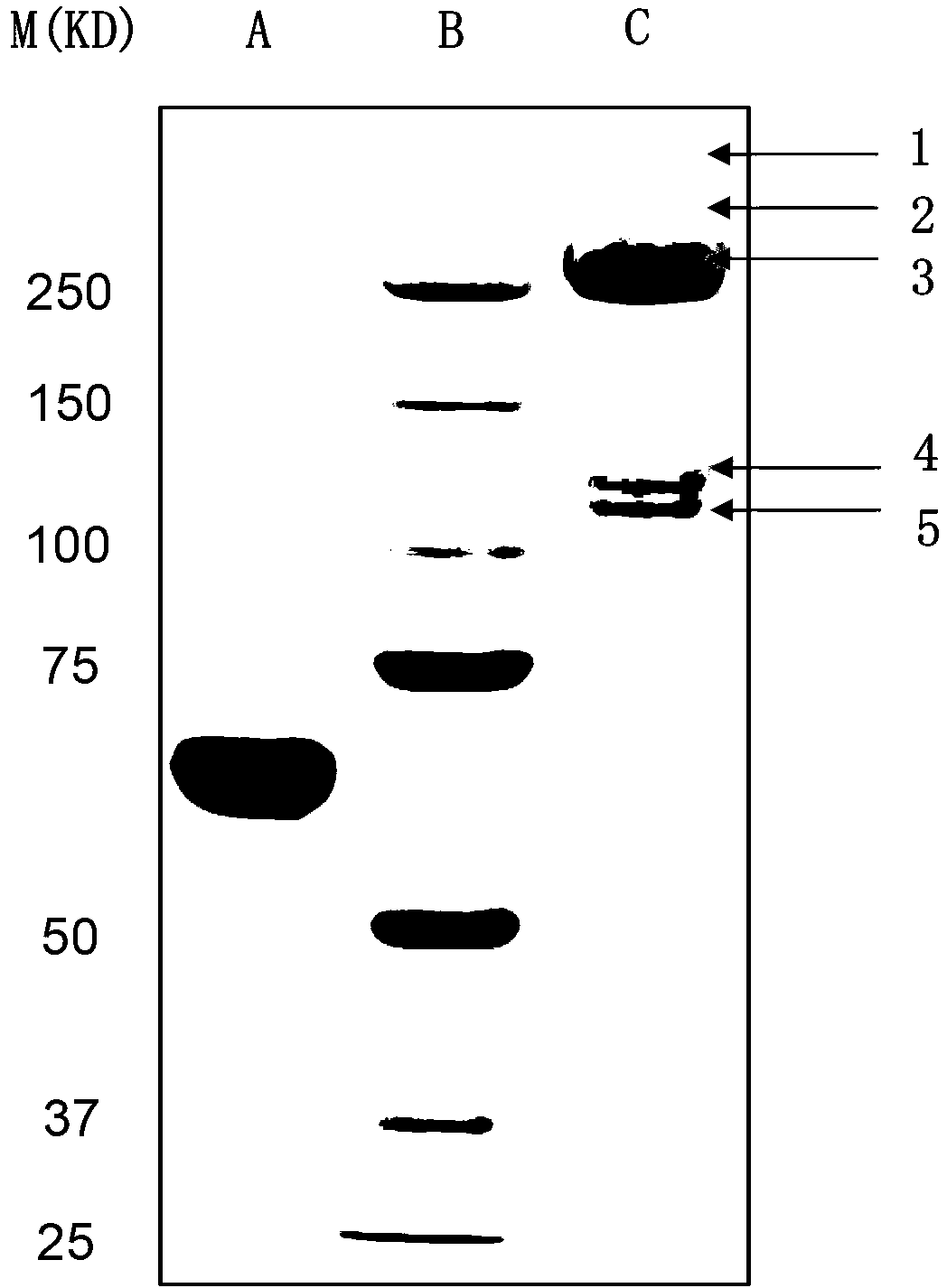

[0036] Put the washed fish skin into a 0.5M phosphoric acid solution at 4°C, stir with a solid-liquid ratio of 1:30, centrifuge at 10,000 rpm at 4°C, and take the supernatant for later use. Then add 0.5M phosphoric acid solution to the centrifuged precipitat...

Embodiment 2

[0040] Take 200g of fresh tilapia skin, remove scales, residual meat and fat, cut into 1cm×1cm small pieces with a slicer, rinse with 20 times of 4°C pure water for 30 minutes, and repeat once, drain the water. Put the fish skin in 4% NaCl solution at 4°C, the ratio of material to liquid is 1:30 (w / w), stir for 36 hours, change the liquid every 8 hours, drain the water, and use deionized water at 4°C 1:20 (w / w) Wash 4 times, 30min each time, drain the water.

[0041] Put the fish skin in 0.1M NaOH solution at 4°C, the ratio of material to liquid is 1:30 (w / w), stir for 48 hours, change the solution every 12 hours, and drain the water. Wash with deionized water at 4°C (1:30w / w) for 3 times, each time for 1 hour, until Ph7-8, and drain the water.

[0042] Put the washed fish skin into 0.5M acetic acid solution at 4°C, with a solid-liquid ratio of 1:30, mash it with a tissue grinder, stir for 4 hours, centrifuge at 10,000 rpm at 4°C, and take the supernatant. Put the precipitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com