Reverse osmosis safety filter with cleaning function and cleaning method thereof

A security filter and filter technology, applied in chemical instruments and methods, reverse osmosis, semi-permeable membrane separation, etc., can solve the problems of reduced water flow and poor water permeability of the filter element, and reduce operating costs and improve water permeability. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

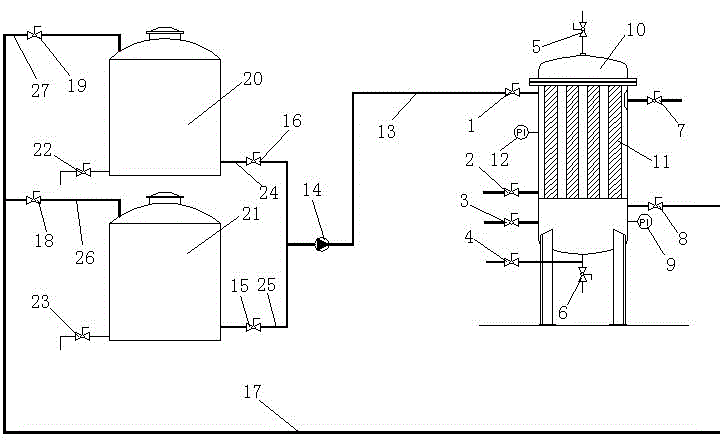

[0026] Embodiment 1: as figure 1 As shown, the following part of the present embodiment describes a reverse osmosis security filter with a cleaning function, which consists of a filter body 10, a cleaning inlet liquid main pipe 13, a cleaning water pump 14, a cleaning liquid return main pipe 17, a sodium hypochlorite tank 20, sub Sodium bisulfate tank 21, sodium hypochlorite liquid inlet pipe 24, sodium bisulfite liquid inlet pipe 25, sodium bisulfite return liquid pipe 26, sodium hypochlorite liquid return pipe 27 form.

[0027] A filter element 11 is arranged in the filter body 10, the upper end of the filter body 10 is the water inlet end, and the lower end is the water outlet end. The filter body 10 is provided with a lower pressure gauge 9 and an upper pressure gauge 12 for measuring pressure. The water inlet end of the filter body 10 is provided with a cleaning liquid inlet valve 1, an air discharge valve 5, and a water inlet valve 7, and the water outlet end of the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com