Efficient energy-saving sewage treatment system

A sewage treatment system, energy-saving technology, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. The problem of single function of the treatment agent can achieve the effect of improving the sewage treatment effect and sewage treatment time, good economic and environmental benefits, and good sewage treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

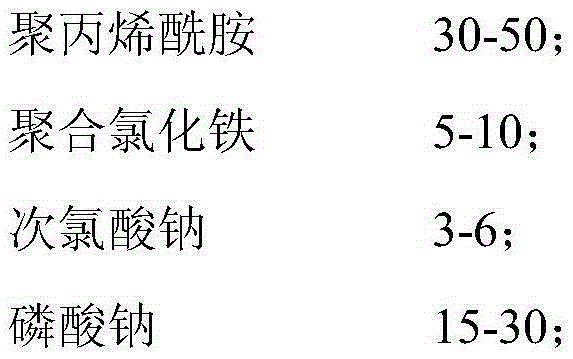

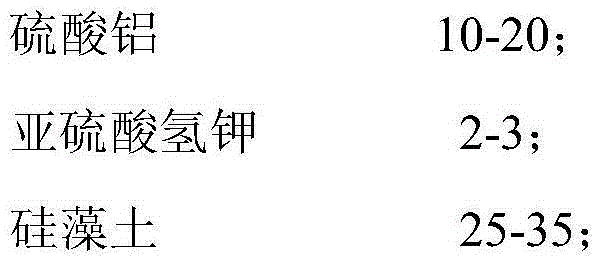

[0025] The water purifying agent adopted in this embodiment includes the following components and parts by weight:

[0026]

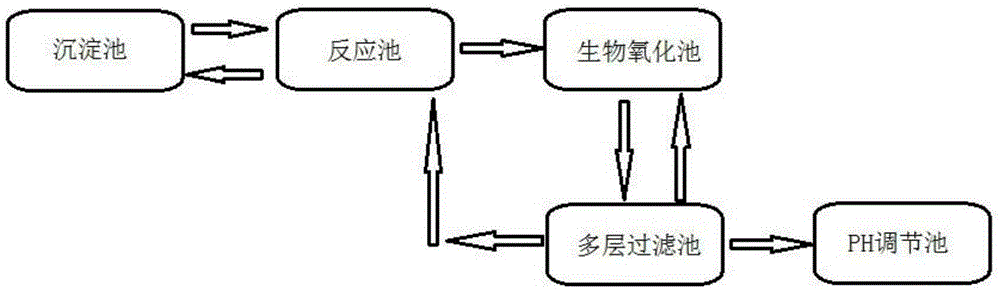

[0027] The sewage is introduced into the sedimentation tank, and after 4 hours of sedimentation, the upper sewage in the sedimentation tank is introduced into the sewage reaction tank, and the sewage in the reaction tank reacts with the water purifier to remove suspended solids and colloidal pollutants. After 0.5h of sedimentation , the upper layer sewage in the reaction tank enters the biological oxidation tank, the lower layer sediment enters the sedimentation tank for circulating sedimentation, and the sewage passing through the biological oxidation tank enters the multi-layer filter tank for filtration. It is 400, 430, 450 and 500 meshes. According to the sediment mesh size obtained by filtration and the effect of sewage treatment, part of the sediment is passed into the biological oxidation tank again for reaction treatment, and part of the sedim...

Embodiment 2

[0030] The water purifying agent adopted in this embodiment includes the following components and parts by weight:

[0031]

[0032]

[0033] The sewage is introduced into the sedimentation tank, and after 4 hours of sedimentation, the upper sewage in the sedimentation tank is introduced into the sewage reaction tank, and the sewage in the reaction tank reacts with the water purifier to remove suspended solids and colloidal pollutants. After 0.5h of sedimentation , the upper layer sewage in the reaction tank enters the biological oxidation tank, the lower layer sediment enters the sedimentation tank for circulating sedimentation, and the sewage passing through the biological oxidation tank enters the multi-layer filter tank for filtration. It is 400, 430, 450 and 500 meshes. According to the sediment mesh size obtained by filtration and the effect of sewage treatment, part of the sediment is passed into the biological oxidation tank again for reaction treatment, and part ...

Embodiment 3

[0036] The water purifying agent adopted in this embodiment includes the following components and parts by weight:

[0037]

[0038] The sewage is introduced into the sedimentation tank, and after 4 hours of sedimentation, the upper sewage in the sedimentation tank is introduced into the sewage reaction tank, and the sewage in the reaction tank reacts with the water purifier to remove suspended solids and colloidal pollutants. After 0.5h of sedimentation , the upper layer sewage in the reaction tank enters the biological oxidation tank, the lower layer sediment enters the sedimentation tank for circulating sedimentation, and the sewage passing through the biological oxidation tank enters the multi-layer filter tank for filtration. It is 400, 430, 450 and 500 meshes. According to the sediment mesh size obtained by filtration and the effect of sewage treatment, part of the sediment is passed into the biological oxidation tank again for reaction treatment, and part of the sedim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com