Attapulgite nickel-plated composite material and preparation method thereof

A technology of attapulgite and composite material, which is applied in the field of attapulgite nickel-plated composite material and its preparation, can solve problems such as reports that have not seen research, and achieve significant economic and social significance, and the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

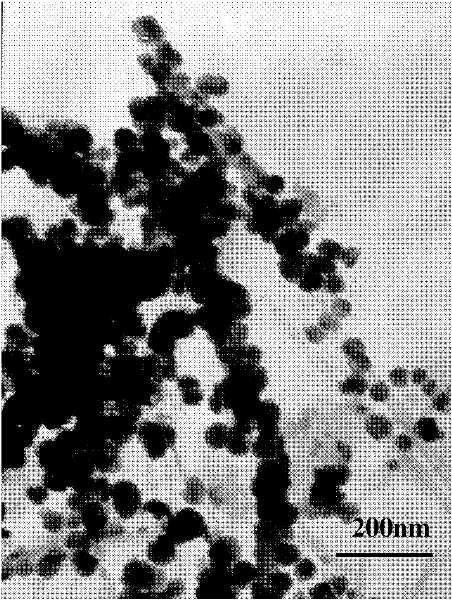

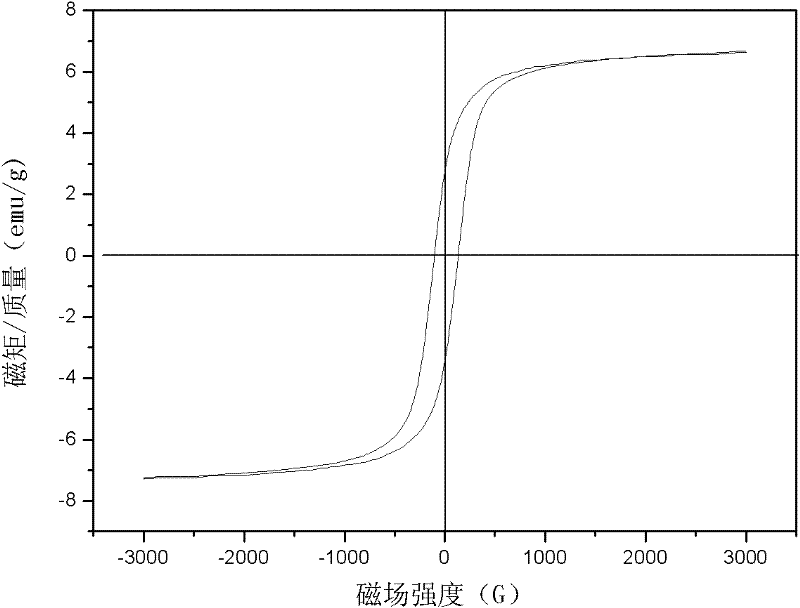

[0030] The attapulgite nickel-plated composite material in this embodiment uses attapulgite as a substrate, and a nickel layer is plated on the attapulgite surface.

[0031] In this embodiment, the attapulgite nickel-plated composite material is prepared according to the following method:

[0032] 1. Prepare 50 mL of attapulgite deionized water suspension with a concentration of 20 g / L, add 100 mg of sodium dodecylbenzene sulfonate to ultrasonically disperse for 20 minutes, and obtain a uniformly dispersed suspension I;

[0033] 2. Add the sensitizing solution to the suspension I, ultrasonically and stir at room temperature for 10 minutes, then centrifuge and reclaim the white sediment, wherein the sensitizing solution is 1.8g stannous chloride, 3.5mL concentrated hydrochloric acid (commercially available analytically pure, Mass concentration is 36-38%) and the mixed solution of 50mL deionized water;

[0034] 3. Add activation solution to the solid phase obtained in step 2, u...

Embodiment 2

[0040] The attapulgite nickel-plated composite material in this embodiment uses attapulgite as a substrate, and a nickel layer is plated on the attapulgite surface.

[0041] In this embodiment, the attapulgite nickel-plated composite material is prepared according to the following method:

[0042] 1. Prepare 40mL of attapulgite deionized water suspension with a concentration of 20g / L, add 100mg sodium dodecylbenzenesulfonate for ultrasonic dispersion for 20 minutes, then add 60mL of 10mol / L concentrated HCl, and let it stand for 12 hours. Sonicate and stir for 30 minutes, centrifuge to collect sediment, wash with deionized water until neutral, add deionized water to make 50mL suspension I;

[0043] 2. Add the sensitizing solution to the suspension I, ultrasonically and stir at room temperature for 10 minutes, then centrifuge and reclaim the white sediment, wherein the sensitizing solution is 1.8g stannous chloride, 3.5mL concentrated hydrochloric acid (commercially available a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com