Spray-drying method of broccoli powder

A processing method and technology of broccoli, applied in the field of food processing, can solve the problems of limited market, short shelf life, inability to utilize raw materials, etc., and achieve the effects of easy digestion, rapid dissolution of solubility, and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

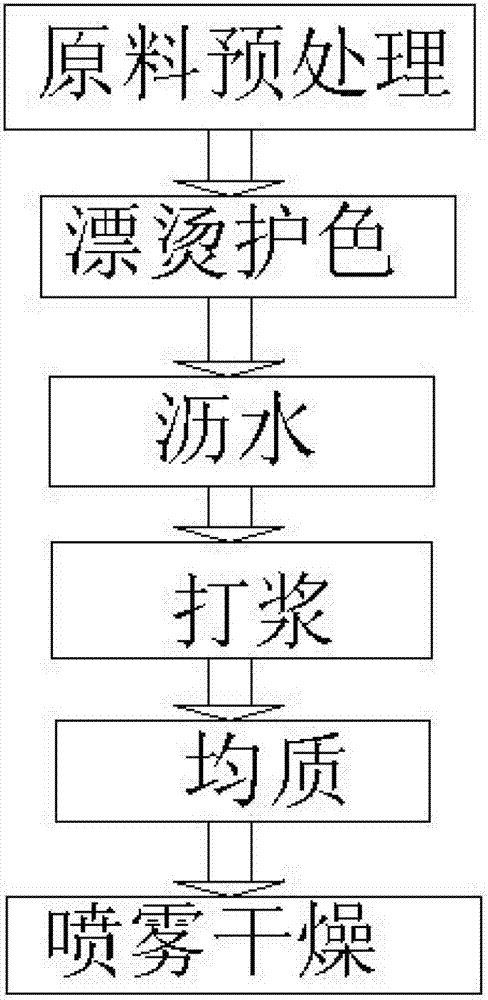

[0033] Embodiment 1, spray drying processing method prepare broccoli vegetable powder

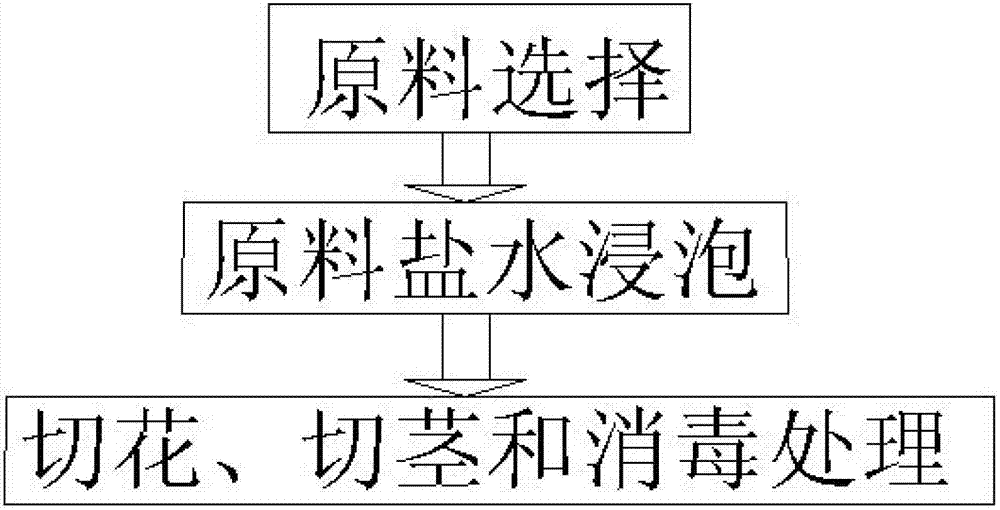

[0034] (1) Step 1, raw material pretreatment: specifically includes ① raw material selection, ② raw material soaking in salt water, and ③ cut flowers, cut stems and disinfection.

[0035] ①The specific steps for raw material selection are: choose broccoli plants with dark green and bright color, no bumps on the surface of the curd, tight and firm flower buds, heavy hand feeling, no damage from diseases and insect pests, basically the same maturity and size, and not too old; fresh Broccoli raw materials should be processed within 24 hours (no more than 30 hours) after picking, otherwise it will bloom, turn yellow and deteriorate, which will affect the quality of the product. Those that cannot be processed in time should be stored in a constant temperature library at 0-3°C.

[0036] ② The specific steps of soaking the raw material in salt water are: soak the raw broccoli selected in the step ①...

Embodiment 2

[0045] Embodiment 2, spray drying processing method prepare broccoli vegetable powder

[0046] The difference with embodiment 1 is:

[0047] In described step 2, with the Cu(AC) of concentration 0.15mg / l 2 As a color-protecting agent, the broccoli pieces obtained in the first step are blanched to protect the color. The conditions for blanching and color protection are as follows: a blanching temperature of 100°C and a blanching time of 2 minutes; Soak the broccoli pieces after the blanching and color protection treatment in cold water; after the second step, use a color difference meter to measure the color difference of the broccoli pieces after blanching and color protection as -12.948±0.142.

[0048] In said step five, the homogeneous pressure is 15MPa.

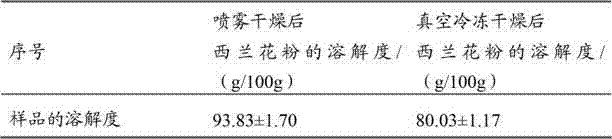

[0049] In the step six, the parameters of spray drying are: inlet temperature 190°C, concentration of broccoli feed liquid 65%, compressed air flow rate 600ml / h. After the sixth step, the measured color difference of th...

Embodiment 3

[0050] Embodiment 3, spray drying processing method prepare broccoli vegetable powder

[0051] The difference with embodiment 1 is:

[0052] In described step 2, with the Cu(AC) of concentration 0.35mg / l 2 As a color-protecting agent, carry out blanching and color-protection to the small pieces of broccoli obtained from the treatment in step 1. The conditions for blanching and color protection are: blanching temperature 75° C., blanching time 1.5 min; after the blanching time ends, Soak the broccoli pieces after the blanching and color protection treatment with cold water; after the step 2 is completed, use a color difference meter to measure the color difference between the broccoli pieces and the raw broccoli after blanching and color protection, and the color difference value It is -12.976±0.197.

[0053] In said step five, the homogeneous pressure is 25MPa.

[0054] In the step six, the parameters of spray drying are: inlet temperature 190°C, concentration of broccoli f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com