Method for preparing multi-level-structured molecular sieve by taking mesoporous material as indirect template agent

A technology of mesoporous materials and templating agents, which is applied in the field of preparing hierarchical molecular sieves, can solve the problems of easy catalyst deactivation, catalyst deactivation, and large diffusion resistance of low-carbon olefins, so as to achieve low value-added by-products and one-way selection. High performance and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1a

[0024] A method for preparing a molecular sieve with a hierarchical structure using a mesoporous material as an indirect template, using 30wt% silica sol as an external silicon source and no external aluminum source; using orthophosphoric acid solution as the phosphorus source in the synthesis raw material; using triethylamine as Template for molecular sieve synthesis.

[0025] A method for preparing a molecular sieve with a hierarchical structure using a mesoporous material as an indirect template includes the following steps:

[0026] 1) Dissolve 10g of aluminum nitrate nonahydrate in 200ml of water and stir and mix for 1.5h, add 5g of glucose, continue to stir until a light yellow mixture is obtained, transfer it to the reactor, and hydrothermally crystallize the product at 200℃ for 12h. After thorough washing with deionized water, drying under vacuum at 70°C overnight, then calcining at 450°C for 7 hours, and finally granulating to obtain mesoporous alumina microspheres with an...

Embodiment 1b

[0033] 1) Measure 10ml of absolute ethanol, 10ml of ammonia, and 100ml of deionized water with a graduated cylinder. Heat the water bath to 40°C and keep at a constant temperature. After stirring for 30 minutes, slowly add ethyl orthosilicate until the mixed solution becomes turbid; stop; Keep the turbid mixed solution in a water bath at 60℃ and continue to stir for 2 hours to form a milky white sol; pour the milky white sol into a glass centrifuge tube for high-speed centrifugation, add the resulting solid product to absolute ethanol for ultrasonic washing until it is washed The latter ethanol solution is neutral. It was dried overnight under vacuum at 70°C, then calcined at 450°C for 7h, and finally granulated to obtain mesoporous silica microspheres with an average particle size of 10μm.

[0034] 2) The mesoporous silica microspheres are mixed with aluminum source, phosphoric acid, template agent and water to form a crystallization stock solution. The template is triethylamine...

Embodiment 2

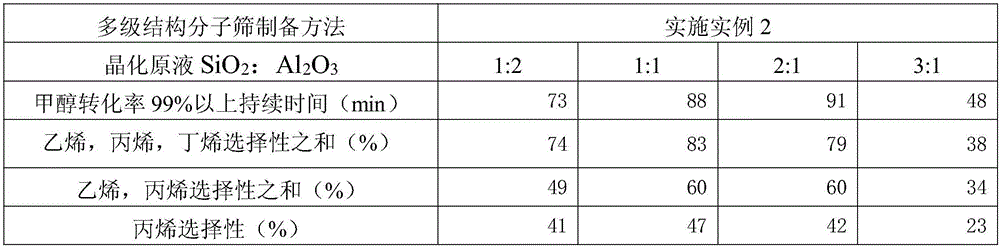

[0051] The synthesis of the multi-stage molecular sieve with mesoporous alumina balls as the aluminum source adopts the hydrothermal method, with 30wt% silica sol as the external silicon source and no external aluminum source; orthophosphoric acid solution as the phosphorus source in the synthesis raw material; Amine is used as template, adjust the content of external silicon source to obtain crystallization stock solution SiO 2 : Al 2 O 3 =1:2; 1:1; 2:1; 3:1 (molar ratio), the remaining steps are the same as in Example 1.

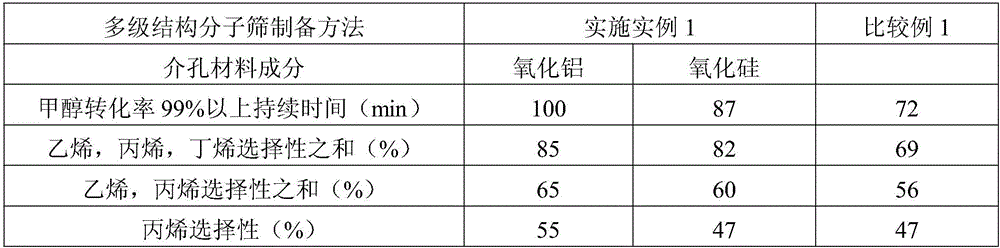

[0052] Effect of Example 2: The reaction conditions are the same as those of Example 1. The activity evaluation results of the multi-stage molecular sieve are shown in Table 2.

[0053] Table 2

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com