A composite component methanation catalyst and its preparation method

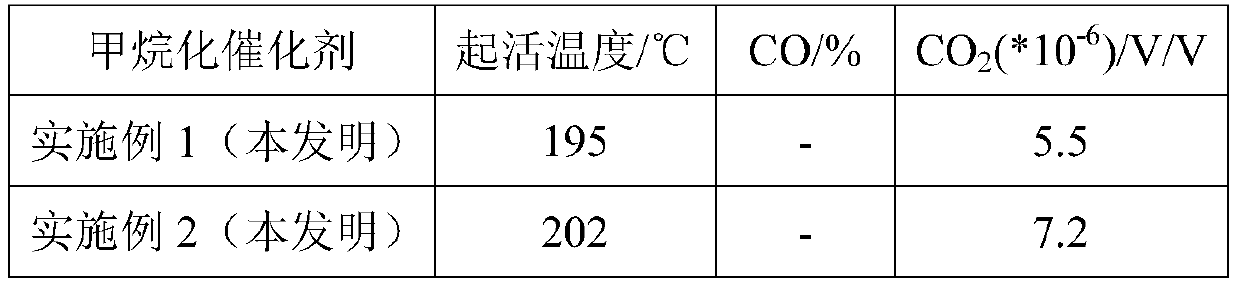

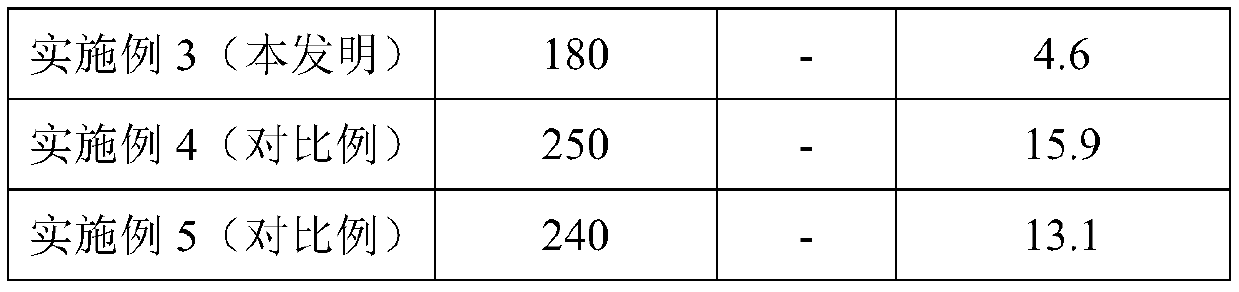

A methanation catalyst and methanation technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of unfavorable industrial application of ruthenium loading and high catalyst cost , the problem of high activation temperature, to achieve the effect of favorable dispersion, high methanation activity and selectivity, and low activation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of composite component methanation catalysts.

[0038] The preparation method comprises the following steps:

[0039] Step 1: Prepare the carrier precursor

[0040] 256g Mg(NO 3 ) 2 ·6H 2 Add 3000mL deionized water to dissolve O, and add 204g γ-Al to the solution 2 o 3 and 80g anatase TiO 2 , after fully stirring and infiltrating, slowly add 5% K 2 CO 3 solution until the pH of the mixed solution was 9. Filter the mixed solution and wash the filter cake until there is no NO 3 - residue. The filter cake was dried at 105° C. for 4 hours, calcined at 400° C. for 5 hours, and passed through a 20-mesh sieve to obtain a carrier precursor.

[0041] Step 2: Prepare the carrier

[0042] The carrier precursor was added with 15% water and 3% graphite by mass, mixed uniformly, pressed and molded, and calcined at 700° C. for 6 hours to obtain a carrier.

[0043] Step 3: Dipping

[0044] Take 1.52g RuCl 3 , 88.00g Ni(NO 3 ) 2 ·6H 2 O, 0.86gLa(NO 3 ) 3 ...

Embodiment 2

[0048] Preparation of composite component methanation catalysts.

[0049] The preparation method comprises the following steps:

[0050] Step 1: Prepare the carrier precursor

[0051] 256g Mg(NO 3 ) 2 ·6H 2 O was dissolved in 3000mL deionized water, and 153g γ-Al was added to the solution 2 o 3 and 40g anatase TiO 2 , after fully stirring and infiltrating, slowly add 5% K 2 CO 3 solution until the pH of the mixed solution was 9. Filter the mixed solution and wash the filter cake until there is no NO3 - residue. The filter cake was dried at 105° C. for 4 hours, calcined at 400° C. for 5 hours, and passed through a 20-mesh sieve to obtain a carrier precursor.

[0052] Step 2: Prepare the carrier

[0053] The carrier precursor was added with 15% water and 3% graphite by mass, mixed uniformly, pressed into shape, and calcined at 800° C. for 6 hours to obtain the carrier.

[0054] Step 3: Dipping

[0055] Take 1.82g RuCl 3 , 90.40g Ni(NO 3 ) 2 ·6H 2 O, 0.93gLa(NO ...

Embodiment 3

[0059] Preparation of composite component methanation catalysts.

[0060] The preparation method comprises the following steps:

[0061] Step 1: Prepare the carrier precursor

[0062] 256Mg(NO 3 ) 2 ·6H 2 O, add 3000mL deionized water to dissolve, add 102g γ-Al to the solution 2 o 3 and 53.33g anatase TiO 2 , after fully stirring and infiltrating, slowly add 5% K 2 CO 3 solution until the pH of the mixed solution was 9. Filter the mixed solution and wash the filter cake until there is no NO 3 - residue. The filter cake was dried at 105° C. for 4 hours, calcined at 400° C. for 5 hours, and passed through a 20-mesh sieve to obtain a carrier precursor.

[0063] Step 2: Prepare the carrier

[0064] The carrier precursor was added with 15% water and 3% graphite by mass, mixed uniformly, pressed into shape, and calcined at 700° C. for 6 hours to obtain a catalyst carrier.

[0065] Step 3: Dipping

[0066] Take 3.05g RuCl 3 , 37.89g Ni(NO 3 ) 2 ·6H 2 O, 1.30gLa(NO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com