Method for preparing molecular sieve with hierarchical structure using mesoporous material as indirect template

A mesoporous material and templating agent technology, which is applied in the field of preparing multi-level molecular sieves, can solve the problems of easy deactivation of catalysts, catalyst deactivation, and high diffusion resistance of low-carbon olefins, and achieve low value-added by-products and one-way selection High performance and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

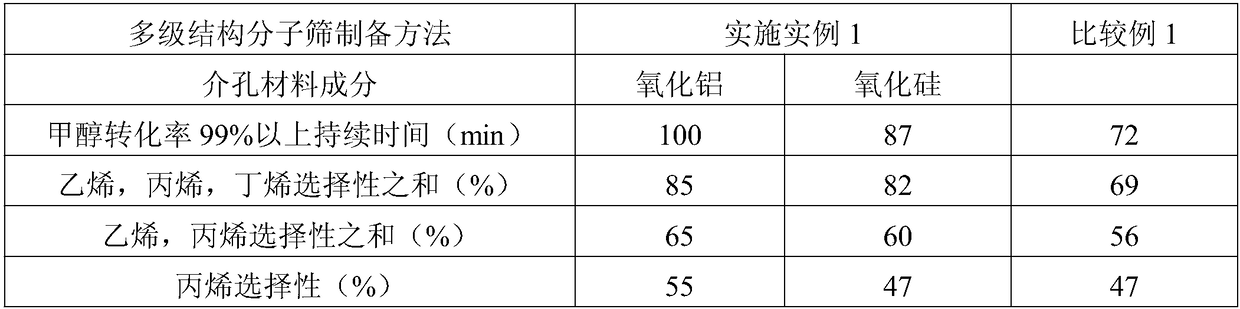

Embodiment 1a

[0024] A method for preparing molecular sieves with a multi-level structure using mesoporous materials as an indirect template, using 30wt% silica sol as an external silicon source without adding an aluminum source; using orthophosphoric acid solution as the phosphorus source in the synthetic raw material; using triethylamine as the Templating agent for molecular sieve synthesis.

[0025] A method for preparing a molecular sieve with a mesoporous material as an indirect template, comprising the steps of:

[0026] 1) Dissolve 10g of aluminum nitrate nonahydrate in 200ml of water and mix thoroughly for 1.5h, add 5g of glucose, continue to stir until a light yellow mixture is obtained, transfer it to a reaction kettle, and use the product obtained by hydrothermal crystallization at 200°C for 12h After fully washing with deionized water, dry at 70°C under vacuum overnight, then bake at 450°C for 7 hours, and finally granulate to obtain mesoporous alumina microspheres with an avera...

Embodiment 1b

[0033] 1) Mix 10ml of absolute ethanol, 10ml of ammonia water, and 100ml of deionized water with a measuring cylinder, heat in a water bath to 40°C, keep a constant temperature, continue stirring for 30min, and slowly add ethyl orthosilicate dropwise until the mixed solution becomes turbid; stop; Keep the turbid mixed solution at 60°C in the water bath, and continue to stir for 2 hours to form a milky white sol; pour the milky white sol into a glass centrifuge tube for high-speed centrifugation, and add the obtained solid product to anhydrous ethanol for ultrasonic washing until washing The final ethanol solution is neutral. Dry overnight at 70°C under vacuum, then calcinate at 450°C for 7 hours, and finally granulate to obtain mesoporous silica microspheres with an average particle size of 10 μm.

[0034] 2) Mix mesoporous silica microspheres, aluminum source, phosphoric acid, template agent and water to form a crystallization stock solution. The template agent is triethylami...

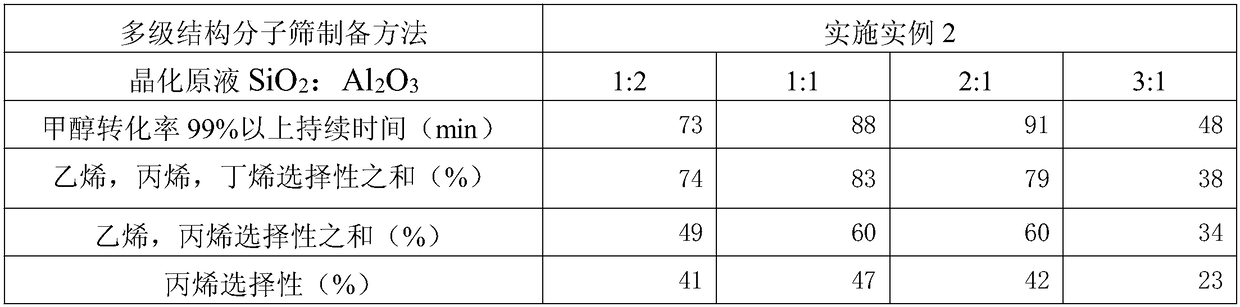

Embodiment 2

[0051] The synthesis of multi-level structure molecular sieves with mesoporous alumina balls as aluminum source adopts hydrothermal method, 30wt% silica sol is used as external silicon source, no aluminum source is added; orthophosphoric acid solution is used as phosphorus source in the synthesis raw material; Amine is used as a template, and the content of the external silicon source is adjusted to obtain the crystallization stock solution SiO 2 :Al 2 o 3 =1:2; 1:1; 2:1; 3:1 (molar ratio), and all the other steps are the same as in Example 1.

[0052] The effect of embodiment 2: reaction condition is the same as implementation example 1, and the activity evaluation result of this hierarchical structure molecular sieve is shown in table 2

[0053] Table 2

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com